Page 48: of Offshore Engineer Magazine (Mar/Apr 2013)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2013 Offshore Engineer Magazine

Internal LDS are well-established for detecting large leaks. However, sensitivity drops during operations that introduce pressure/fow variations (eg startup, shut-in, valve closures, transient fow, etc).

These events can be misinterpreted,

Subsea leading to false alarms. Such systems can be integrated into a pipeline’s SCADA to record all large leaks (typically, above 1% of nominal fow rate). Systems usually detect large leaks in 30 seconds and small leaks within 24 hours. External LDS can quickly detect and locate small leaks below the minimum thresholds of internal 2

LDS, and provide information for

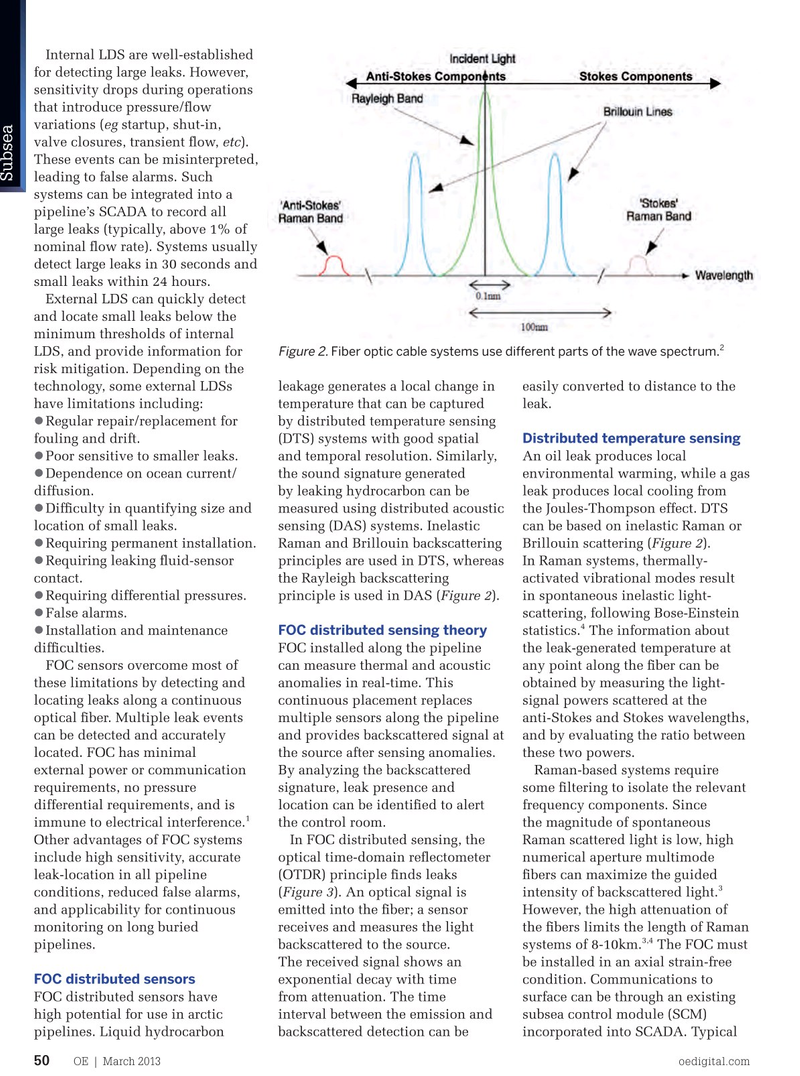

Figure 2. Fiber optic cable systems use different parts of the wave spectrum.

risk mitigation. Depending on the technology, some external LDSs leakage generates a local change in easily converted to distance to the have limitations including: temperature that can be captured leak.

l Regular repair/replacement for by distributed temperature sensing fouling and drift. (DTS) systems with good spatial Distributed temperature sensing l Poor sensitive to smaller leaks. and temporal resolution. Similarly, An oil leak produces local l Dependence on ocean current/ the sound signature generated environmental warming, while a gas diffusion. by leaking hydrocarbon can be leak produces local cooling from l Diffculty in quantifying size and measured using distributed acoustic the Joules-Thompson effect. DTS location of small leaks. sensing (DAS) systems. Inelastic can be based on inelastic Raman or l Requiring permanent installation. Raman and Brillouin backscattering Brillouin scattering (Figure 2). l Requiring leaking fuid-sensor principles are used in DTS, whereas In Raman systems, thermally- contact. the Rayleigh backscattering activated vibrational modes result l Requiring differential pressures. principle is used in DAS (Figure 2). in spontaneous inelastic light- l False alarms. scattering, following Bose-Einstein 4 l Installation and maintenance FOC distributed sensing theory statistics. The information about diffculties. FOC installed along the pipeline the leak-generated temperature at FOC sensors overcome most of can measure thermal and acoustic any point along the fber can be these limitations by detecting and anomalies in real-time. This obtained by measuring the light- locating leaks along a continuous continuous placement replaces signal powers scattered at the optical fber. Multiple leak events multiple sensors along the pipeline anti-Stokes and Stokes wavelengths, can be detected and accurately and provides backscattered signal at and by evaluating the ratio between located. FOC has minimal the source after sensing anomalies. these two powers. external power or communication By analyzing the backscattered Raman-based systems require requirements, no pressure signature, leak presence and some fltering to isolate the relevant differential requirements, and is location can be identifed to alert frequency components. Since 1 immune to electrical interference. the control room. the magnitude of spontaneous

Other advantages of FOC systems In FOC distributed sensing, the Raman scattered light is low, high include high sensitivity, accurate optical time-domain refectometer numerical aperture multimode leak-location in all pipeline (OTDR) principle fnds leaks fbers can maximize the guided 3 conditions, reduced false alarms, (Figure 3). An optical signal is intensity of backscattered light. and applicability for continuous emitted into the fber; a sensor However, the high attenuation of monitoring on long buried receives and measures the light the fbers limits the length of Raman 3,4 pipelines. backscattered to the source. systems of 8-10km. The FOC must

The received signal shows an be installed in an axial strain-free

FOC distributed sensors exponential decay with time condition. Communications to

FOC distributed sensors have from attenuation. The time surface can be through an existing high potential for use in arctic interval between the emission and subsea control module (SCM) pipelines. Liquid hydrocarbon backscattered detection can be incorporated into SCADA. Typical

OE | March 2013 oedigital.com 50 oe_subseaINTECSEA_rev3.indd 50 27/02/2013 11:55

47

47

49

49