Page 49: of Offshore Engineer Magazine (Mar/Apr 2013)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2013 Offshore Engineer Magazine

spatial resolution is of the order that affect the maximum coverage of one meter and temperature length for the system. Therefore, 3 resolution is 0.2°C. cable connections onshore, in-water cable splices, and those at offshore

Subsea

Distributed acoustic sensing facilities should be limited by

DAS uses a monitoring instrument maximizing the cable reel size. at one end of the pipeline and two or more fbers within a FOC bundle Technology gaps to detect leakage. The FOC acts as a Key technology gaps associated distributed hydrophone system that with the FOC-based, Arctic, offshore picks up sound from leakage. When pipeline, leak detection include: a leak’s sound signature is detected, uncertain minimum detection location information is sent and thresholds, false alarm reduction, an alarm is triggered. OTDR in the FOC on long pipelines, reliability

Rayleigh band monitors acoustic quantifcation, installation, and signals. The backscattered signals, maintenance.

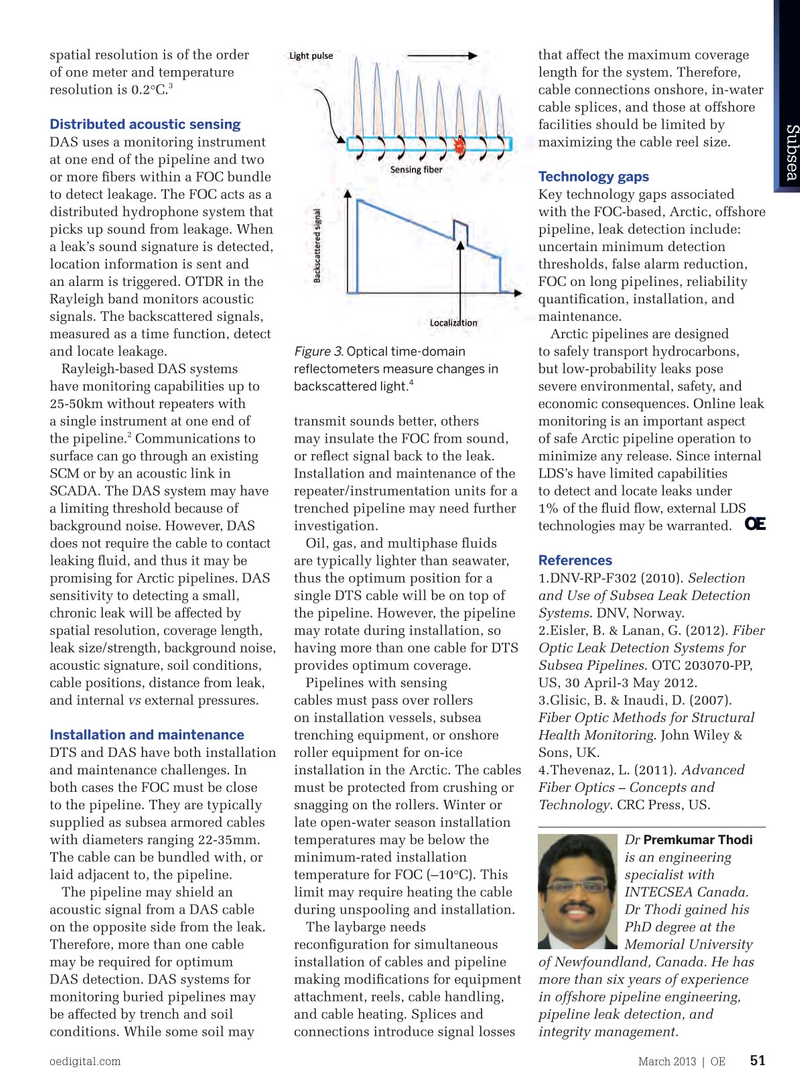

measured as a time function, detect Arctic pipelines are designed and locate leakage. to safely transport hydrocarbons,

Figure 3. Optical time-domain Rayleigh-based DAS systems but low-probability leaks pose refectometers measure changes in 4 have monitoring capabilities up to severe environmental, safety, and backscattered light.

25-50km without repeaters with economic consequences. Online leak a single instrument at one end of transmit sounds better, others monitoring is an important aspect 2 the pipeline. Communications to may insulate the FOC from sound, of safe Arctic pipeline operation to surface can go through an existing or refect signal back to the leak. minimize any release. Since internal

SCM or by an acoustic link in Installation and maintenance of the LDS’s have limited capabilities

SCADA. The DAS system may have repeater/instrumentation units for a to detect and locate leaks under a limiting threshold because of trenched pipeline may need further 1% of the fuid fow, external LDS background noise. However, DAS investigation. technologies may be warranted. does not require the cable to contact Oil, gas, and multiphase fuids leaking fuid, and thus it may be are typically lighter than seawater, References promising for Arctic pipelines. DAS thus the optimum position for a 1. DNV-RP-F302 (2010). Selection sensitivity to detecting a small, single DTS cable will be on top of and Use of Subsea Leak Detection chronic leak will be affected by the pipeline. However, the pipeline Systems. DNV, Norway.

spatial resolution, coverage length, may rotate during installation, so 2. Eisler, B. & Lanan, G. (2012). Fiber leak size/strength, background noise, having more than one cable for DTS Optic Leak Detection Systems for acoustic signature, soil conditions, provides optimum coverage. Subsea Pipelines. OTC 203070-PP, cable positions, distance from leak, Pipelines with sensing US, 30 April-3 May 2012.

and internal vs external pressures. cables must pass over rollers 3. Glisic, B. & Inaudi, D. (2007). on installation vessels, subsea Fiber Optic Methods for Structural

Installation and maintenance trenching equipment, or onshore Health Monitoring. John Wiley &

DTS and DAS have both installation roller equipment for on-ice Sons, UK.

and maintenance challenges. In installation in the Arctic. The cables 4. Thevenaz, L. (2011). Advanced both cases the FOC must be close must be protected from crushing or Fiber Optics – Concepts and to the pipeline. They are typically snagging on the rollers. Winter or Technology. CRC Press, US.

supplied as subsea armored cables late open-water season installation with diameters ranging 22-35mm. temperatures may be below the Dr

Premkumar Thodi

The cable can be bundled with, or minimum-rated installation is an engineering laid adjacent to, the pipeline. temperature for FOC (–10°C). This specialist with The pipeline may shield an limit may require heating the cable INTECSEA Canada. acoustic signal from a DAS cable during unspooling and installation. Dr Thodi gained his on the opposite side from the leak. The laybarge needs PhD degree at the

Therefore, more than one cable reconfguration for simultaneous Memorial University may be required for optimum installation of cables and pipeline of Newfoundland, Canada. He has

DAS detection. DAS systems for making modifcations for equipment more than six years of experience monitoring buried pipelines may attachment, reels, cable handling, in offshore pipeline engineering, be affected by trench and soil and cable heating. Splices and pipeline leak detection, and conditions. While some soil may connections introduce signal losses integrity management.

oedigital.com March 2013 | OE 51 oe_subseaINTECSEA_rev3.indd 51 27/02/2013 11:56

48

48

50

50