Page 60: of Offshore Engineer Magazine (Apr/May 2013)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2013 Offshore Engineer Magazine

Subsea cable overheating risk

Subsea reduced by monitoring

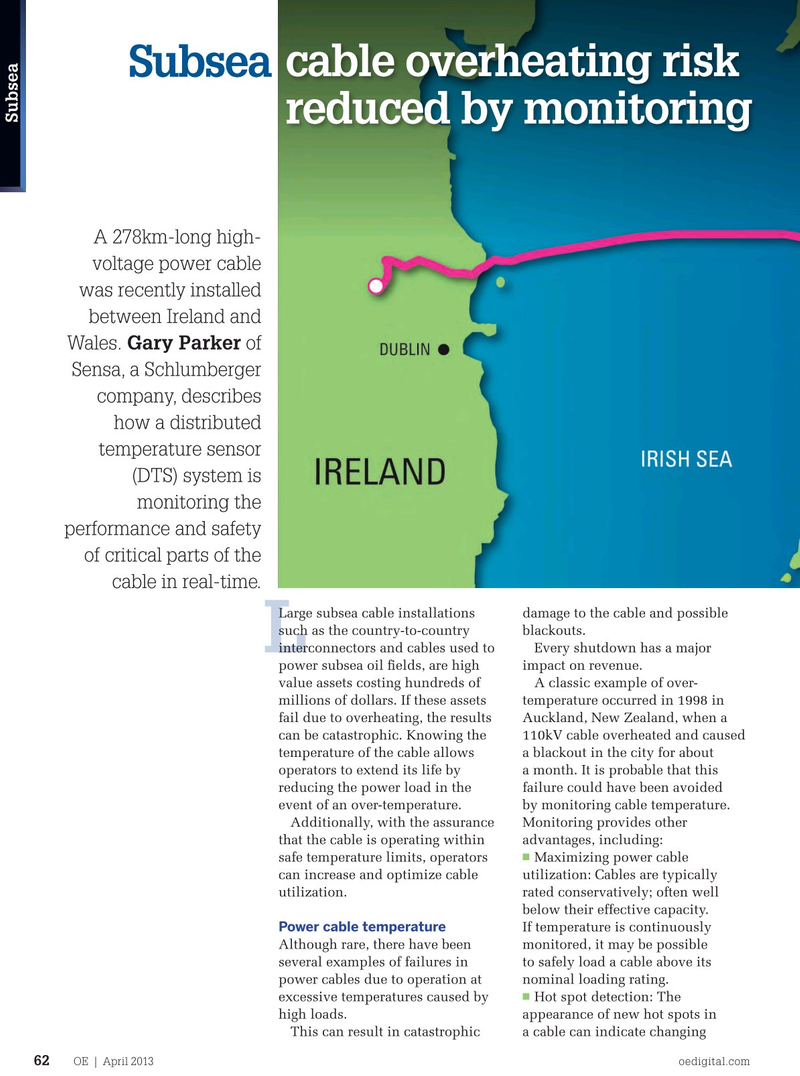

A 278km-long high- voltage power cable was recently installed between Ireland and

Wales. Gary Parker of

Sensa, a Schlumberger company, describes how a distributed temperature sensor (DTS) system is monitoring the performance and safety of critical parts of the cable in real-time.

Large subsea cable installations damage to the cable and possible such as the country-to-country blackouts. interconnectors and cables used to Every shutdown has a major

L power subsea oil felds, are high impact on revenue. value assets costing hundreds of A classic example of over- millions of dollars. If these assets temperature occurred in 1998 in fail due to overheating, the results Auckland, New Zealand, when a can be catastrophic. Knowing the 110kV cable overheated and caused temperature of the cable allows a blackout in the city for about operators to extend its life by a month. It is probable that this reducing the power load in the failure could have been avoided event of an over-temperature. by monitoring cable temperature. Additionally, with the assurance Monitoring provides other that the cable is operating within advantages, including: n safe temperature limits, operators Maximizing power cable can increase and optimize cable utilization: Cables are typically utilization. rated conservatively; often well below their effective capacity.

Power cable temperature If temperature is continuously

Although rare, there have been monitored, it may be possible several examples of failures in to safely load a cable above its power cables due to operation at nominal loading rating.

n excessive temperatures caused by Hot spot detection: The high loads. appearance of new hot spots in This can result in catastrophic a cable can indicate changing

OE | April 2013 oedigital.com 62 oe_subseaSCHLUM_v2_single pages.indd 62 4/1/13 2:16 AM

59

59

61

61