Page 61: of Offshore Engineer Magazine (Apr/May 2013)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2013 Offshore Engineer Magazine

are simple to operate and are

Subsea reasonably accurate. Resistance temperature detectors (RTDs) are another common type of sensor.

They offer higher precision than thermocouples, but are more expensive and are relatively fragile.

In cable-rating, a resolution of ±1°C is often more than adequate, therefore higher resolution provides no beneft. One disadvantage of thermocouples and RTDs is that they are susceptible to electromagnetic interference (EMI), which may distort the temperature reading. An alternative is to use thermo-optical temperature sensors.

Semiconductor-based temperature sensors, which can also use infrared, are not affected by EMI and are more suitable for cable monitoring.

A key disadvantage inherent to monitoring the temperature of a long cable with point measurements is that they only detect the temperature at discrete

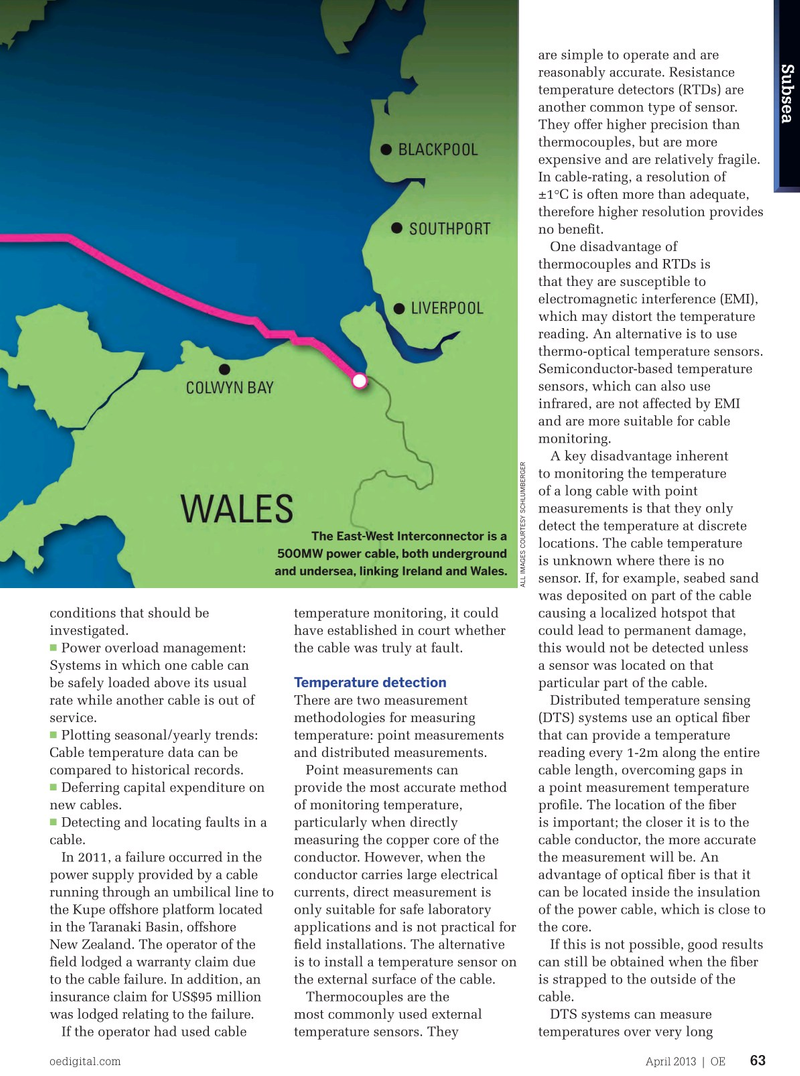

The East-West Interconnector is a locations. The cable temperature 500MW power cable, both underground is unknown where there is no and undersea, linking Ireland and Wales.

sensor. If, for example, seabed sand allimagescourtesyschlumberger was deposited on part of the cable conditions that should be temperature monitoring, it could causing a localized hotspot that investigated. have established in court whether could lead to permanent damage, n Power overload management: the cable was truly at fault. this would not be detected unless

Systems in which one cable can a sensor was located on that be safely loaded above its usual Temperature detection particular part of the cable.

rate while another cable is out of There are two measurement Distributed temperature sensing service. methodologies for measuring (DTS) systems use an optical fber n Plotting seasonal/yearly trends: temperature: point measurements that can provide a temperature

Cable temperature data can be and distributed measurements. reading every 1-2m along the entire compared to historical records. Point measurements can cable length, overcoming gaps in n Deferring capital expenditure on provide the most accurate method a point measurement temperature new cables. of monitoring temperature, profle. The location of the fber n Detecting and locating faults in a particularly when directly is important; the closer it is to the cable. measuring the copper core of the cable conductor, the more accurate In 2011, a failure occurred in the conductor. However, when the the measurement will be. An power supply provided by a cable conductor carries large electrical advantage of optical fber is that it running through an umbilical line to currents, direct measurement is can be located inside the insulation the Kupe offshore platform located only suitable for safe laboratory of the power cable, which is close to in the Taranaki Basin, offshore applications and is not practical for the core.

New Zealand. The operator of the feld installations. The alternative If this is not possible, good results feld lodged a warranty claim due is to install a temperature sensor on can still be obtained when the fber to the cable failure. In addition, an the external surface of the cable. is strapped to the outside of the insurance claim for US$95 million Thermocouples are the cable.

was lodged relating to the failure. most commonly used external DTS systems can measure If the operator had used cable temperature sensors. They temperatures over very long oedigital.com April 2013 | OE 63 oe_subseaSCHLUM_v2_single pages.indd 63 4/1/13 2:17 AM

60

60

62

62