Page 57: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

can be easily manufactured locally in decrease the density of the mix, tests (density; modulus of elasticity;

EPIC large quantities. making it a very light and a good shear modulus; Poisson coeffcient;

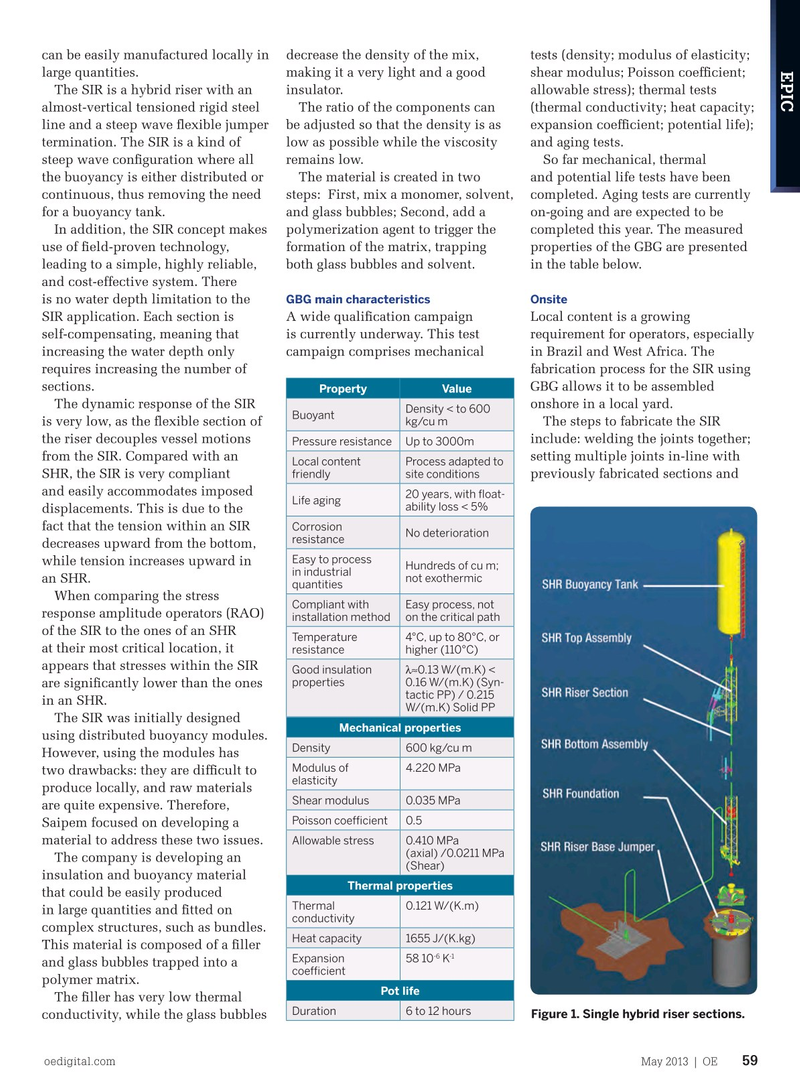

The SIR is a hybrid riser with an insulator. allowable stress); thermal tests almost-vertical tensioned rigid steel The ratio of the components can (thermal conductivity; heat capacity; line and a steep wave fexible jumper be adjusted so that the density is as expansion coeffcient; potential life); termination. The SIR is a kind of low as possible while the viscosity and aging tests. steep wave confguration where all remains low. So far mechanical, thermal the buoyancy is either distributed or The material is created in two and potential life tests have been continuous, thus removing the need steps: First, mix a monomer, solvent, completed. Aging tests are currently for a buoyancy tank. and glass bubbles; Second, add a on-going and are expected to be

In addition, the SIR concept makes polymerization agent to trigger the completed this year. The measured use of feld-proven technology, formation of the matrix, trapping properties of the GBG are presented leading to a simple, highly reliable, both glass bubbles and solvent. in the table below.

and cost-effective system. There

GBG main characteristics Onsite is no water depth limitation to the

SIR application. Each section is A wide qualifcation campaign Local content is a growing self-compensating, meaning that is currently underway. This test requirement for operators, especially increasing the water depth only campaign comprises mechanical in Brazil and West Africa. The requires increasing the number of fabrication process for the SIR using sections. GBG allows it to be assembled

Property Value

The dynamic response of the SIR onshore in a local yard.

Density < to 600

Buoyant kg/cu m is very low, as the fexible section of The steps to fabricate the SIR the riser decouples vessel motions include: welding the joints together;

Pressure resistanceUp to 3000m from the SIR. Compared with an setting multiple joints in-line with

Local content Process adapted to

SHR, the SIR is very compliant previously fabricated sections and friendly site conditions and easily accommodates imposed 20 years, with foat-

Life aging ability loss < 5% displacements. This is due to the fact that the tension within an SIR

Corrosion

No deterioration resistance decreases upward from the bottom,

Easy to process while tension increases upward in

Hundreds of cu m; in industrial not exothermic an SHR. quantities

When comparing the stress

Compliant with Easy process, not response amplitude operators (RAO) installation method on the critical path of the SIR to the ones of an SHR

Temperature 4°C, up to 80°C, or at their most critical location, it resistance higher (110°C) appears that stresses within the SIR

Good insulation ?˜0.13 W/(m.K) < properties 0.16 W/(m.K) (Syn- are signifcantly lower than the ones tactic PP) / 0.215 in an SHR.

W/(m.K) Solid PP

The SIR was initially designed

Mechanical properties using distributed buoyancy modules.

Density 600 kg/cu m

However, using the modules has

Modulus of 4.220 MPa two drawbacks: they are diffcult to elasticity produce locally, and raw materials

Shear modulus0.035 MPa are quite expensive. Therefore,

Poisson coeffcient 0.5

Saipem focused on developing a material to address these two issues.

Allowable stress0.410 MPa (axial) /0.0211 MPa

The company is developing an (Shear) insulation and buoyancy material

Thermal properties that could be easily produced

Thermal 0.121 W/(K.m) in large quantities and ftted on conductivity complex structures, such as bundles.

Heat capacity1655 J/(K.kg)

This material is composed of a fller -6 -1

Expansion 58 10 K and glass bubbles trapped into a coeffcient polymer matrix.

Pot life

The fller has very low thermal

Duration 6 to 12 hours

Figure 1. Single hybrid riser sections.

conductivity, while the glass bubbles oedigital.com May 2013 | OE 59 (2)EPIC1_glassbubbles_Saipem.indd 59 4/22/13 3:21 AM

56

56

58

58