Page 58: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

EPIC

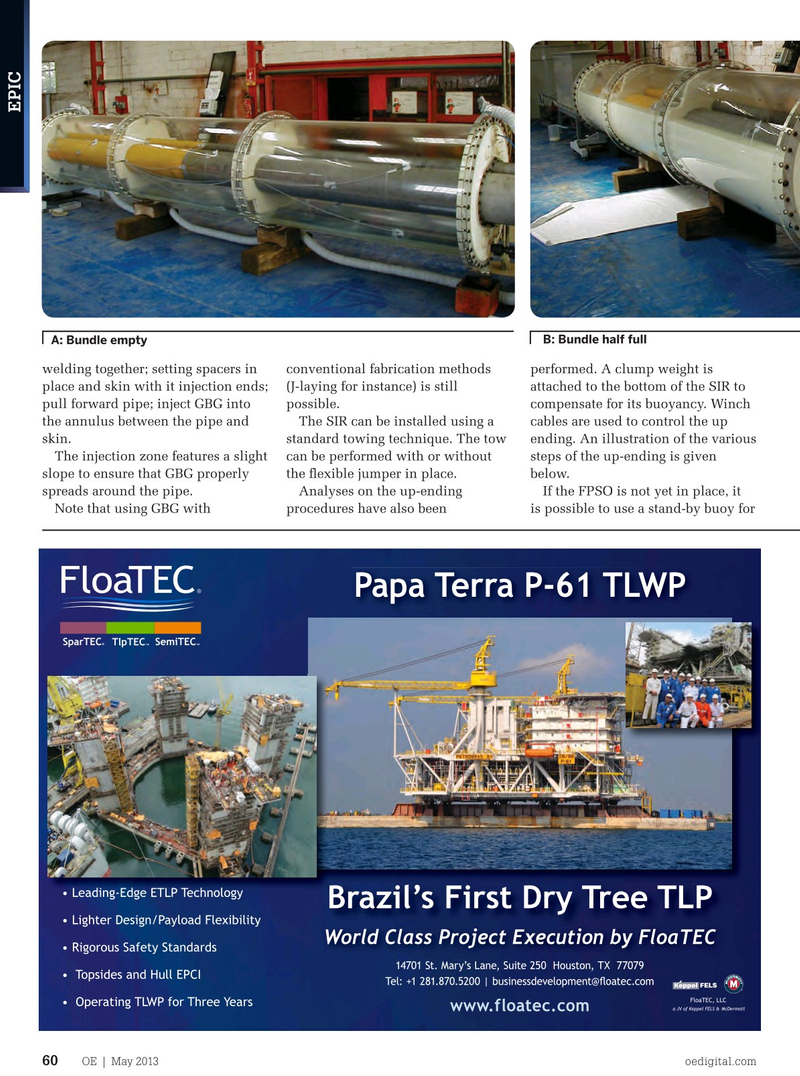

A: Bundle empty B: Bundle half full welding together; setting spacers in conventional fabrication methods performed. A clump weight is place and skin with it injection ends; (J-laying for instance) is still attached to the bottom of the SIR to pull forward pipe; inject GBG into possible. compensate for its buoyancy. Winch the annulus between the pipe and The SIR can be installed using a cables are used to control the up skin. standard towing technique. The tow ending. An illustration of the various

The injection zone features a slight can be performed with or without steps of the up-ending is given slope to ensure that GBG properly the fexible jumper in place. below.

spreads around the pipe. Analyses on the up-ending If the FPSO is not yet in place, it

Note that using GBG with procedures have also been is possible to use a stand-by buoy for

Papa Terra P-61 TLWP • Leading-Edge ETLP TechnologyLeading-Edge ETLP Technology

Brazil’s First Dry Tree TLPBrazil’s First Dry Tree TLP • Lighter Design/Payload Flexibility

World Class Project Execution by FloaTEC • Rigorous Safety Standards 14701 St. Mary’s Lane, Suite 250 Houston, TX 77079 • Topsides and Hull EPCI

Tel: +1 281.870.5200 | businessdevelopment@? oatec.com

FloaTEC, LLC • Operating TLWP for Three Years www.floatec.com

OE | May 2013 oedigital.com 60

Untitled-1 60 4/22/13 3:24 PM

57

57

59

59