Page 27: of Offshore Engineer Magazine (Jun/Jul 2013)

Read this page in Pdf, Flash or Html5 edition of Jun/Jul 2013 Offshore Engineer Magazine

The ’s Noble Globetrotter II

Then, in 2007, Huisman

Drilling hoistable construction foor.

was contracted to work with Frontier Drilling and 61m-high, dual multipurpose Shell to design its frst drilling tower (DMPT) with DMPT and related pipe, two 1090-ton capacity hoist riser and BOP handling systems on either side, one equipment for Frontier’s above the well center in the frst drillship, the Bully I drill foor and the other above (now working in the Gulf the center in the construction of Mexico) and then a year foor. The construction side later for a second ship, is for 135ft stand building, the Bully II (working off the handling of large subsea Brazil). structures, the BOP, and “Shell wanted to not running risers, which can go in with a bigger ham- be while drilling the surface mer, but see how it could hole. be done smarter, Shell’s

The construction foor can vision was not to use a be hoisted in order to skid bigger hammer, but to fnd the BOP or Xmas tree under- a way smarter way,” said neath and positioned before Roodenburg. lowering into the moonpool. Both Bully vessels had

This means the construction already been designed (by foor, and consequently the GustoMSC) with a view drill foor, can be low, reduc- to have traditional der- ing the center of gravity and ricks when Huisman was minimizing lifting activities. brought in, which meant

Due to the lowered tower retroftting the tower into and drill foor, an exhaust the design. outlet could be placed above “This was the start,” a forward accommodation block, the the vessel better. said Roodenburg. “That gave us the engine rooms could be moved forward The frst, a multipurpose tower chance to put up our tower and we of the tower, creating space for up to (MPT), was built in 2000 to go on Helix then saw an opportunity to challenge 9900ft of risers (3000 tons worth) in a Energy’s Q4000 well intervention semi- the whole vessel design using the hold, and opening deck space covered submersible, delivered in 2001. The thinking we had started on the semis, by a gantry crane. use of an MPT instead of a traditional with our tower as the center point.”

According to Huisman, these drill-derrick structure with its limit- Work on the HuisDrill design then improvements have led to a vessel that ing “V-doors,” meant different drilling started, with Noble Drilling becoming is 50% smaller than a conventional packages could be skidded in, enabling involved ahead of taking over Frontier, drillship, but with the same capacity. fexible use. in 2011, while the Bully vessels were

It also means it is Panamax size and, thanks to a removable section at the top of the DMPT, it can ft through the Panama canal, the Suez, and also under the Bosphorus’ bridge.

The design idea started when Huisman carried out work on the Pride Amethyst 2

Class semisubmersible rigs, 1995-1998.

Huisman was not providing the tower at this stage, but, looking at the inter- face between the derrick and the vessel,

Huisman questioned the point loads created by the derrick’s four legs. This resulted in the idea for a different type of tower to interface and spread load on

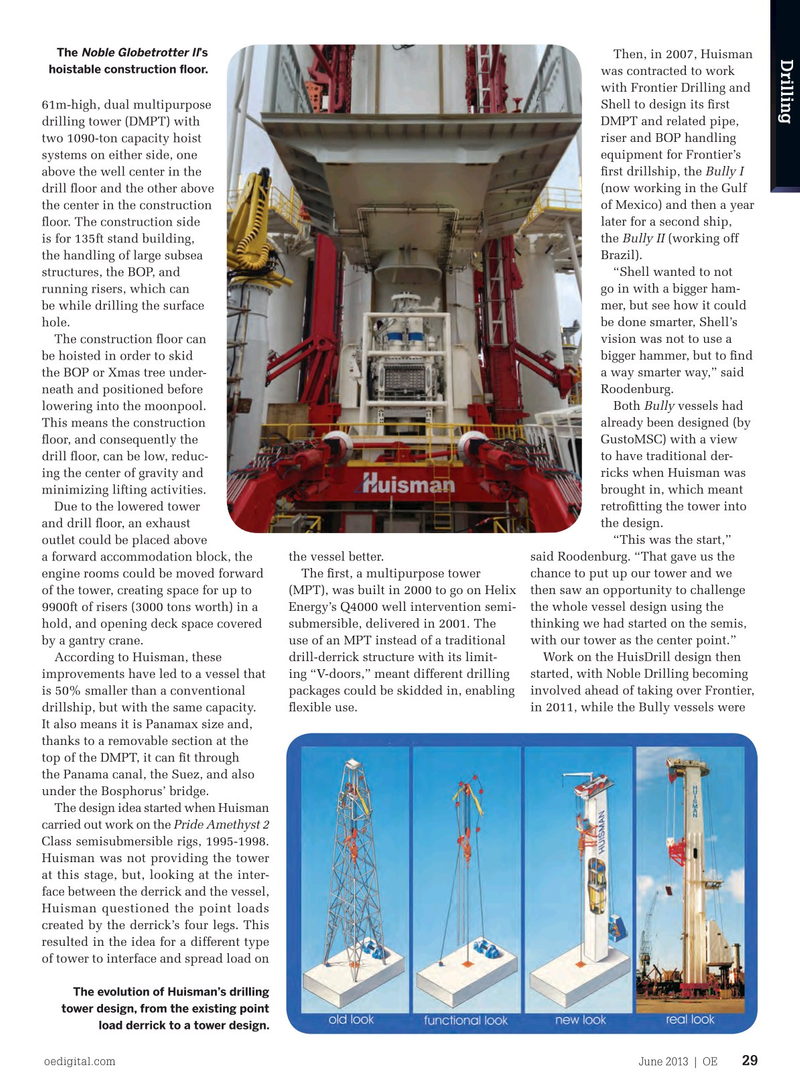

The evolution of Huisman’s drilling tower design, from the existing point load derrick to a tower design.

oedigital.com June 2013 | OE 29 028OE_0613_DC_Huisman.indd 29 5/28/13 9:18 AM

26

26

28

28