Page 45: of Offshore Engineer Magazine (Jun/Jul 2013)

Read this page in Pdf, Flash or Html5 edition of Jun/Jul 2013 Offshore Engineer Magazine

Flowlines 20000 60000 18000 50000 16000 14000 40000 12000 10000 30000 8000 20000 6000

Micelle-Like Particles 4000

Micelle-Like Particles 10000 2000 0 0

InputOutput Input Input Output Output Output

Low Dose High Dose Low Dose Increasing Dose High Dose

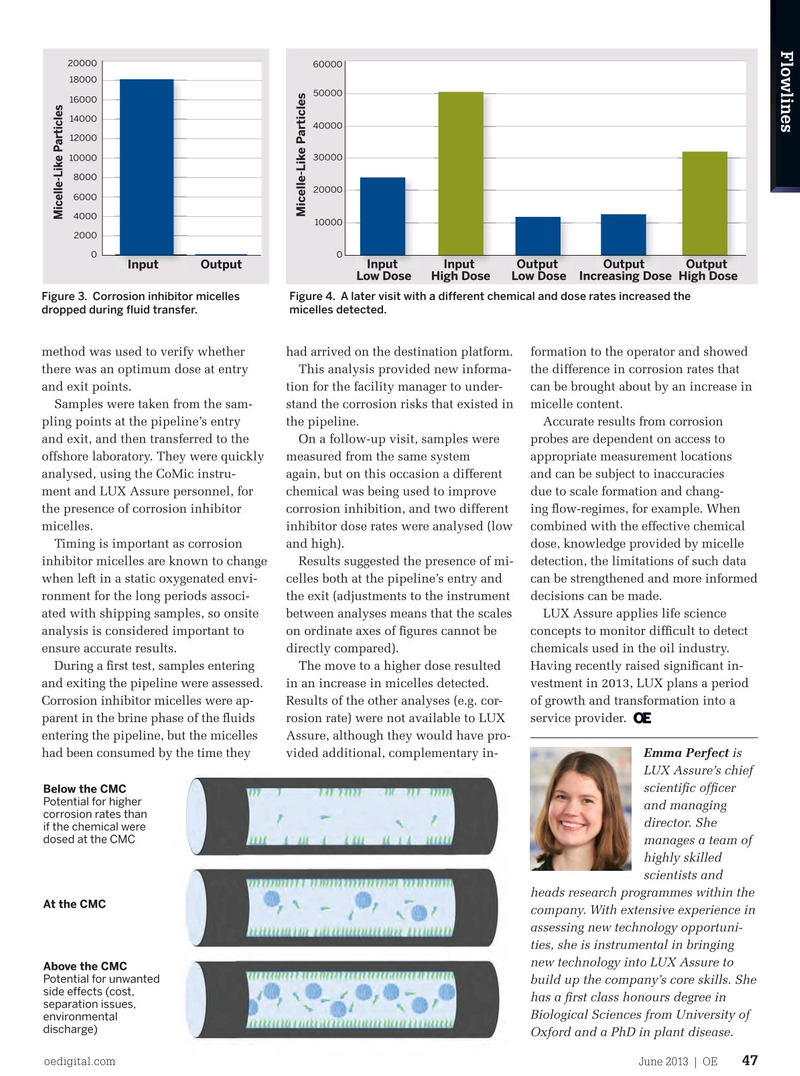

Figure 3. Corrosion inhibitor micelles Figure 4. A later visit with a different chemical and dose rates increased the dropped during fluid transfer. micelles detected.

method was used to verify whether had arrived on the destination platform. formation to the operator and showed there was an optimum dose at entry This analysis provided new informa- the difference in corrosion rates that and exit points. tion for the facility manager to under- can be brought about by an increase in

Samples were taken from the sam- stand the corrosion risks that existed in micelle content. pling points at the pipeline’s entry the pipeline. Accurate results from corrosion and exit, and then transferred to the On a follow-up visit, samples were probes are dependent on access to offshore laboratory. They were quickly measured from the same system appropriate measurement locations analysed, using the CoMic instru- again, but on this occasion a different and can be subject to inaccuracies ment and LUX Assure personnel, for chemical was being used to improve due to scale formation and chang- the presence of corrosion inhibitor corrosion inhibition, and two different ing fow-regimes, for example. When micelles. inhibitor dose rates were analysed (low combined with the effective chemical

Timing is important as corrosion and high). dose, knowledge provided by micelle inhibitor micelles are known to change Results suggested the presence of mi- detection, the limitations of such data when left in a static oxygenated envi- celles both at the pipeline’s entry and can be strengthened and more informed ronment for the long periods associ- the exit (adjustments to the instrument decisions can be made.

ated with shipping samples, so onsite between analyses means that the scales LUX Assure applies life science analysis is considered important to on ordinate axes of fgures cannot be concepts to monitor diffcult to detect ensure accurate results. directly compared). chemicals used in the oil industry.

During a frst test, samples entering The move to a higher dose resulted Having recently raised signifcant in- and exiting the pipeline were assessed. in an increase in micelles detected. vestment in 2013, LUX plans a period

Corrosion inhibitor micelles were ap- Results of the other analyses (e.g. cor- of growth and transformation into a parent in the brine phase of the fuids rosion rate) were not available to LUX service provider. entering the pipeline, but the micelles Assure, although they would have pro- had been consumed by the time they vided additional, complementary in- Emma Perfect is

LUX Assure’s chief scientifc offcer

Below the CMC

Potential for higher and managing corrosion rates than director. She if the chemical were dosed at the CMC manages a team of highly skilled scientists and heads research programmes within the

At the CMC company. With extensive experience in assessing new technology opportuni- ties, she is instrumental in bringing new technology into LUX Assure to

Above the CMC

Potential for unwanted build up the company’s core skills. She side effects (cost, has a frst class honours degree in separation issues,

Biological Sciences from University of environmental discharge)

Oxford and a PhD in plant disease.

oedigital.com June 2013 | OE 47 046OE_0613_Flowlines_LUX.indd 47 5/27/13 3:50 PM

44

44

46

46