Page 109: of Offshore Engineer Magazine (Sep/Oct 2013)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2013 Offshore Engineer Magazine

Pipelines offshore locations with by fashed gas, causing gas under-

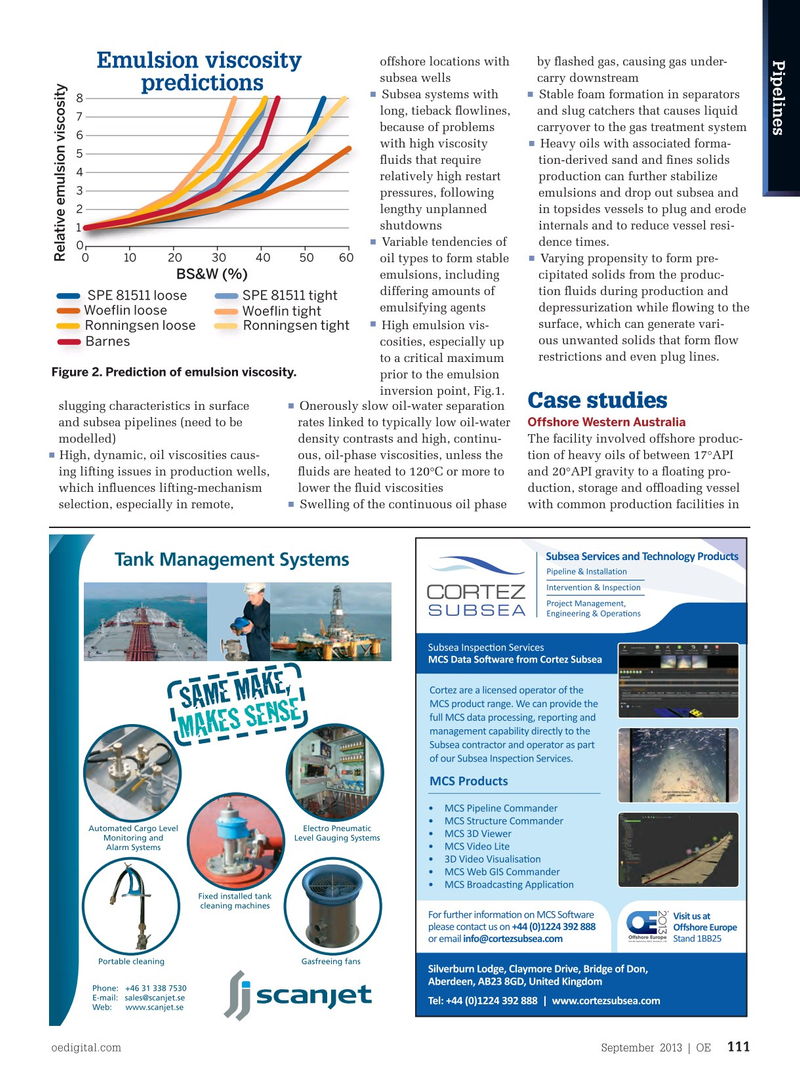

Emulsion viscosity subsea wells carry downstream predictions n n Subsea systems with Stable foam formation in separators 8 long, tieback fowlines, and slug catchers that causes liquid 7 because of problems carryover to the gas treatment system 6 n with high viscosity Heavy oils with associated forma- 5 fuids that require tion-derived sand and fnes solids 4 relatively high restart production can further stabilize 3 pressures, following emulsions and drop out subsea and lengthy unplanned in topsides vessels to plug and erode 2 shutdowns internals and to reduce vessel resi- 1 n Variable tendencies of dence times.

0 n 0 10 20 30 40 50 60

Relative emulsion viscosity oil types to form stable Varying propensity to form pre- emulsions, including cipitated solids from the produc-

BS&W (%) differing amounts of tion fuids during production and

SPE 81511 loose SPE 81511 tight emulsifying agents depressurization while fowing to the

Woeflin loose Woeflin tight n surface, which can generate vari- High emulsion vis-

Ronningsen loose Ronningsen tight ous unwanted solids that form fow cosities, especially up

Barnes restrictions and even plug lines. to a critical maximum

Figure 2. Prediction of emulsion viscosity.

prior to the emulsion inversion point, Fig.1.

Case studies n slugging characteristics in surface Onerously slow oil-water separation and subsea pipelines (need to be rates linked to typically low oil-water

Offshore Western Australia density contrasts and high, continu- modelled) The facility involved offshore produc- n ous, oil-phase viscosities, unless the High, dynamic, oil viscosities caus- tion of heavy oils of between 17°API fuids are heated to 120°C or more to ing lifting issues in production wells, and 20°API gravity to a foating pro- lower the fuid viscosities which infuences lifting-mechanism duction, storage and offoading vessel n Swelling of the continuous oil phase selection, especially in remote, with common production facilities in

Subsea Services and Technology Products

Tank Management Systems

Pipeline & Installation

Intervention & Inspection

Project Management,

Engineering & Operat ons

Subsea Inspect on Services

MCS Data Sof ware from Cortez Subsea

Cortez are a licensed operator of the

MCS product range. We can provide the

SAME MAKE, full MCS data processing, reporting and management capability directly to the

MAKES SENSE

Subsea contractor and operator as part of our Subsea Inspection Services.

MCS Products • MCS Pipeline Commander • MCS Structure Commander

Automated Cargo Level Electro Pneumatic • MCS 3D Viewer

Monitoring and Level Gauging Systems • MCS Video Lite

Alarm Systems • 3D Video Visualisat on • MCS Web GIS Commander • MCS Broadcast ng Applicat on

Fixed installed tank cleaning machines

For further informat on on MCS Sof ware

Visit us at please contact us on +44 (0)1224 392 888

Offshore Europe

Stand 1BB25 or email [email protected]

Portable cleaning Gasfreeing fans

Silverburn Lodge, Claymore Drive, Bridge of Don,

Aberdeen, AB23 8GD, United Kingdom

Phone: +46 31 338 7530

E-mail: [email protected]

Tel: +44 (0)1224 392 888 | www.cortezsubsea.com

Web: www.scanjet.se oedigital.com September 2013 | OE 111 000_OE0913_pipelines_maxoil.indd 111 8/17/13 5:54 PM

108

108

110

110