Page 83: of Offshore Engineer Magazine (Sep/Oct 2013)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2013 Offshore Engineer Magazine

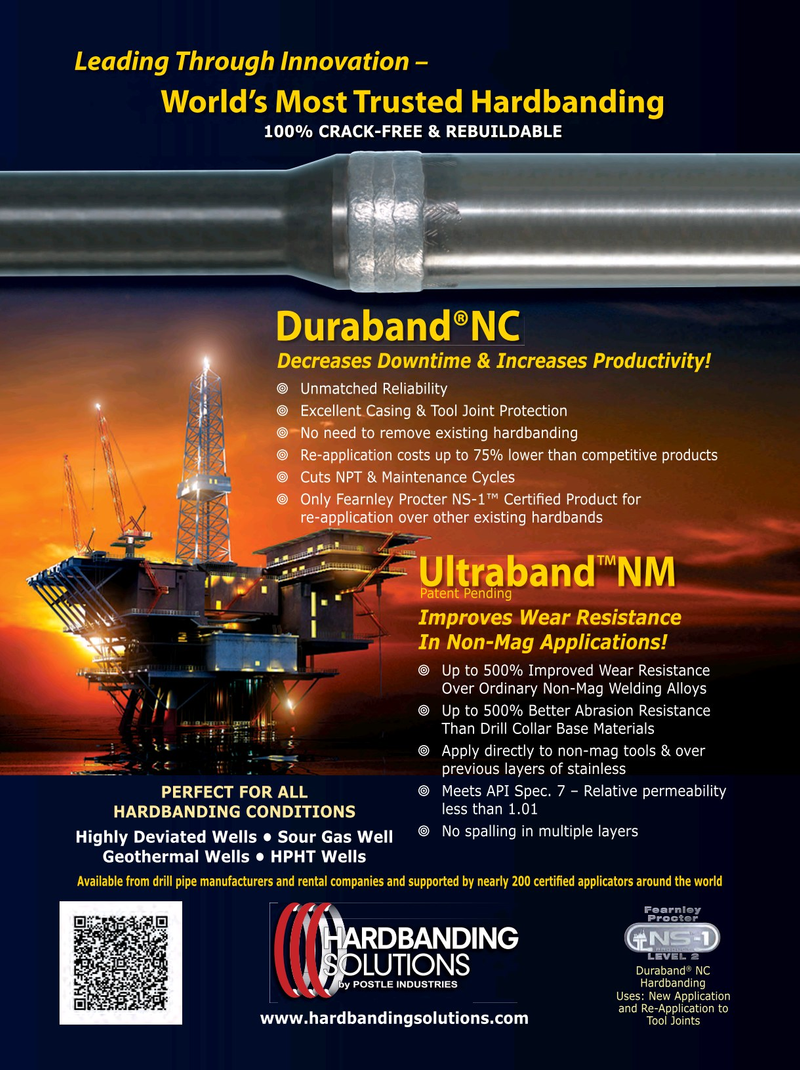

Leading Through Innovation –

World’s Most Trusted Hardbanding 100% crAcK-free & rebuildAble

Duraband®NC

Decreases Downtime & Increases Productivity!

•

Unmatched Reliability •

Excellent Casing & Tool Joint Protection •

No need to remove existing hardbanding

Re-application costs up to 75% lower than competitive products •

Cuts NPT & Maintenance Cycles •

Only Fearnley Procter NS-1™ Certifed Product for • re-application over other existing hardbands ™

Ultraband NM

Patent Pending

Improves Wear Resistance

In Non-Mag Applications!

• Up to 500% Improved Wear Resistance

Over Ordinary Non-Mag Welding Alloys

Up to 500% Better Abrasion Resistance •

Than Drill Collar Base Materials

Apply directly to non-mag tools & over • previous layers of stainless

Meets API Spec. 7 – Relative permeability •

Perfect for All less than 1.01

HArdbAnding conditions •

No spalling in multiple layers

Highly deviated Wells • sour gas Well geothermal Wells • HPHt Wells

Available from drill pipe manufacturers and rental companies and supported by nearly 200 certifed applicators around the world ®

Duraband NC

Hardbanding

Uses: New Application and Re-Application to www.hardbandingsolutions.com

Tool Joints

82

82

84

84