Page 37: of Offshore Engineer Magazine (Nov/Dec 2013)

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2013 Offshore Engineer Magazine

Production performance of another. Moreover, such

PI Conventional

Single orifce at bpd/ design orifce at Digital gas lift limited information can actually increase 4,190 ft.

psi 6,770 ft.

the chances of well instability, leading to potential surges in liquid and gas fow.

Gas lift Gas lift Gas lift Depth of

Oil bo/d Oil bo/d Oil bo/d

MMSCFD MMSCFD MMSCFD Injection

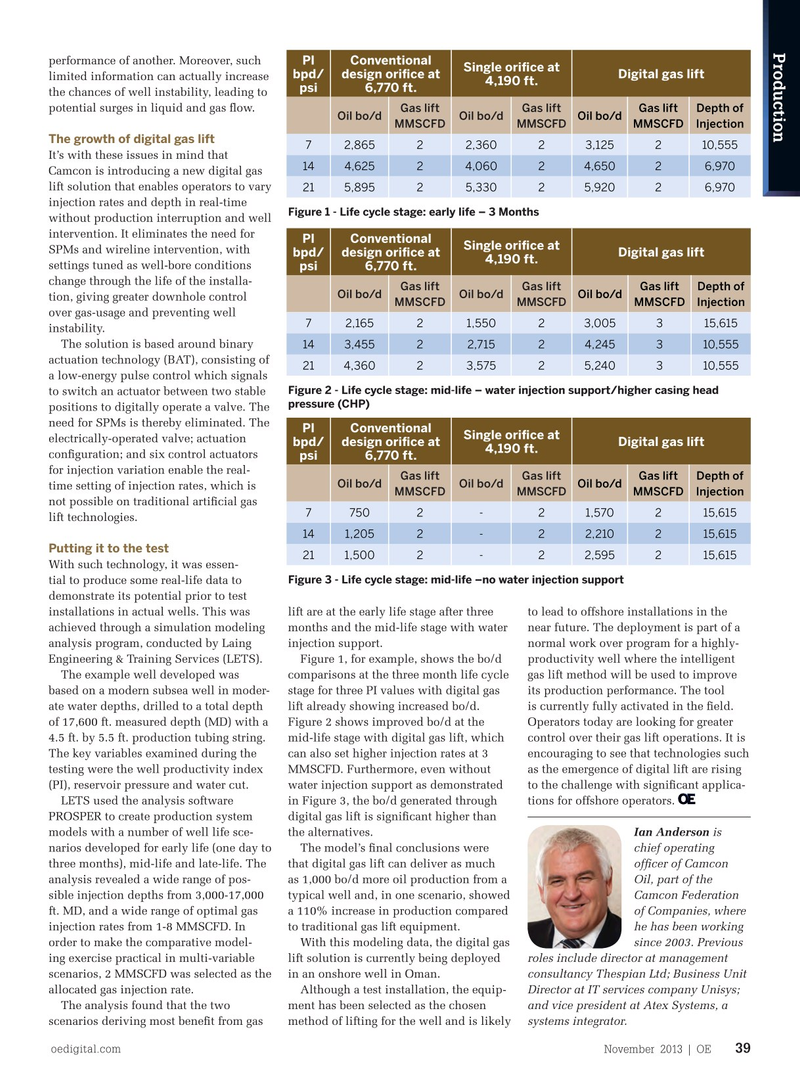

The growth of digital gas lift 7 2,865 2 2,360 2 3,125 2 10,555

It’s with these issues in mind that 14 4,625 2 4,060 2 4,650 2 6,970

Camcon is introducing a new digital gas lift solution that enables operators to vary 21 5,895 2 5,330 2 5,920 2 6,970 injection rates and depth in real-time

Figure 1 - Life cycle stage: early life – 3 Months without production interruption and well intervention. It eliminates the need for

PI Conventional

Single orifce at

SPMs and wireline intervention, with bpd/ design orifce at Digital gas lift 4,190 ft.

settings tuned as well-bore conditions psi 6,770 ft.

change through the life of the installa-

Gas lift Gas lift Gas lift Depth of

Oil bo/d Oil bo/d Oil bo/d tion, giving greater downhole control

MMSCFD MMSCFD MMSCFD Injection over gas-usage and preventing well 7 2,165 2 1,550 2 3,005 3 15,615 instability.

The solution is based around binary 14 3,455 2 2,715 2 4,245 3 10,555 actuation technology (BAT), consisting of 21 4,360 2 3,575 2 5,240 3 10,555 a low-energy pulse control which signals

Figure 2 - Life cycle stage: mid-life – water injection support/higher casing head to switch an actuator between two stable pressure (CHP) positions to digitally operate a valve. The need for SPMs is thereby eliminated. The

PI Conventional

Single orifce at electrically-operated valve; actuation bpd/ design orifce at Digital gas lift 4,190 ft.

confguration; and six control actuators psi 6,770 ft.

for injection variation enable the real-

Gas lift Gas lift Gas lift Depth of

Oil bo/d Oil bo/d Oil bo/d time setting of injection rates, which is

MMSCFD MMSCFD MMSCFD Injection not possible on traditional artifcial gas 7 750 2-2 1,570 2 15,615 lift technologies.

14 1,205 2-2 2,210 2 15,615

Putting it to the test 21 1,500 2-2 2,595 2 15,615

With such technology, it was essen-

Figure 3 - Life cycle stage: mid-life –no water injection support tial to produce some real-life data to demonstrate its potential prior to test installations in actual wells. This was lift are at the early life stage after three to lead to offshore installations in the achieved through a simulation modeling months and the mid-life stage with water near future. The deployment is part of a analysis program, conducted by Laing injection support. normal work over program for a highly-

Engineering & Training Services (LETS). Figure 1, for example, shows the bo/d productivity well where the intelligent

The example well developed was comparisons at the three month life cycle gas lift method will be used to improve based on a modern subsea well in moder- stage for three PI values with digital gas its production performance. The tool ate water depths, drilled to a total depth lift already showing increased bo/d. is currently fully activated in the feld.

of 17,600 ft. measured depth (MD) with a Figure 2 shows improved bo/d at the Operators today are looking for greater 4.5 ft. by 5.5 ft. production tubing string. mid-life stage with digital gas lift, which control over their gas lift operations. It is

The key variables examined during the can also set higher injection rates at 3 encouraging to see that technologies such testing were the well productivity index MMSCFD. Furthermore, even without as the emergence of digital lift are rising (PI), reservoir pressure and water cut. water injection support as demonstrated to the challenge with signifcant applica-

LETS used the analysis software in Figure 3, the bo/d generated through tions for offshore operators.

PROSPER to create production system digital gas lift is signifcant higher than models with a number of well life sce- the alternatives. Ian Anderson is narios developed for early life (one day to The model’s fnal conclusions were chief operating three months), mid-life and late-life. The that digital gas lift can deliver as much offcer of Camcon analysis revealed a wide range of pos- as 1,000 bo/d more oil production from a Oil, part of the sible injection depths from 3,000-17,000 typical well and, in one scenario, showed Camcon Federation ft. MD, and a wide range of optimal gas a 110% increase in production compared of Companies, where injection rates from 1-8 MMSCFD. In to traditional gas lift equipment. he has been working order to make the comparative model- With this modeling data, the digital gas since 2003. Previous ing exercise practical in multi-variable lift solution is currently being deployed roles include director at management scenarios, 2 MMSCFD was selected as the in an onshore well in Oman. consultancy Thespian Ltd; Business Unit allocated gas injection rate. Although a test installation, the equip- Director at IT services company Unisys;

The analysis found that the two ment has been selected as the chosen and vice president at Atex Systems, a scenarios deriving most beneft from gas method of lifting for the well and is likely systems integrator.

oedigital.com November 2013 | OE 39 000_OE1113_ProdOps2_Camcon.indd 39 10/28/13 1:42 AM

36

36

38

38