Page 38: of Offshore Engineer Magazine (Nov/Dec 2013)

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2013 Offshore Engineer Magazine

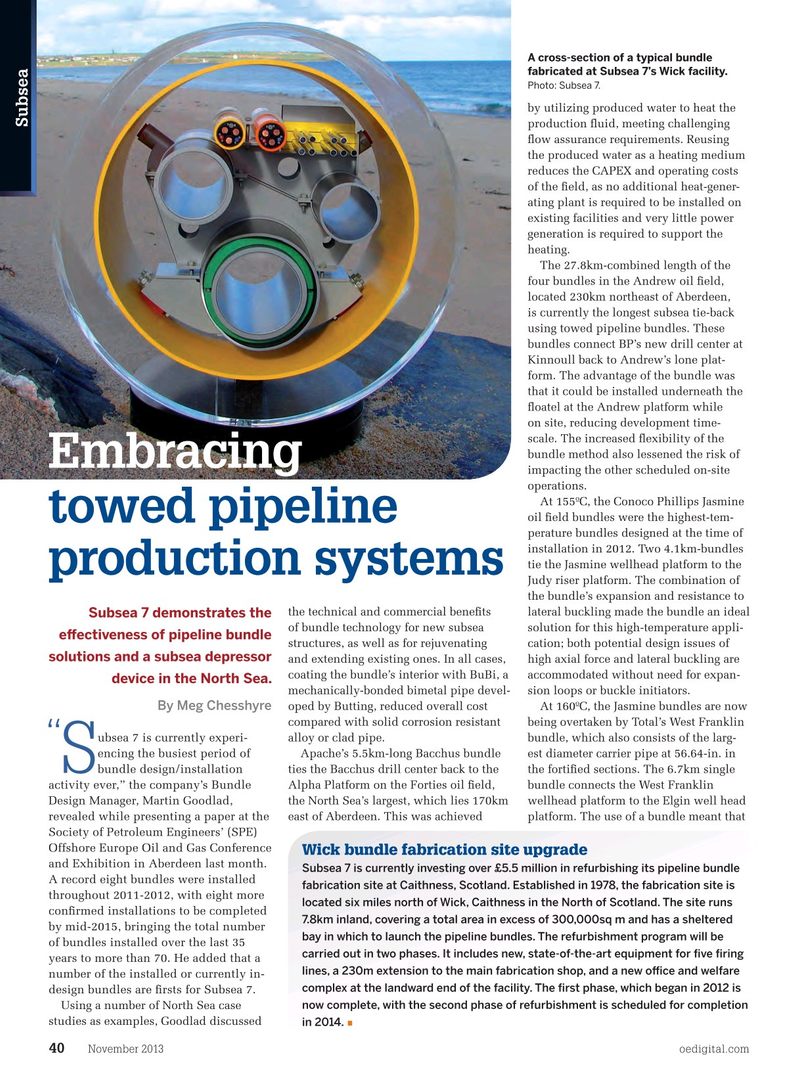

A cross-section of a typical bundle fabricated at Subsea 7’s Wick facility.

Photo: Subsea 7.

by utilizing produced water to heat the

Subsea production fuid, meeting challenging fow assurance requirements. Reusing the produced water as a heating medium reduces the CAPEX and operating costs of the feld, as no additional heat-gener- ating plant is required to be installed on existing facilities and very little power generation is required to support the heating.

The 27.8km-combined length of the four bundles in the Andrew oil feld, located 230km northeast of Aberdeen, is currently the longest subsea tie-back using towed pipeline bundles. These bundles connect BP’s new drill center at

Kinnoull back to Andrew’s lone plat- form. The advantage of the bundle was that it could be installed underneath the foatel at the Andrew platform while on site, reducing development time- scale. The increased fexibility of the bundle method also lessened the risk of

Embracing impacting the other scheduled on-site operations.

At 155ºC, the Conoco Phillips Jasmine oil feld bundles were the highest-tem- towed pipeline perature bundles designed at the time of installation in 2012. Two 4.1km-bundles tie the Jasmine wellhead platform to the production systems

Judy riser platform. The combination of the bundle’s expansion and resistance to the technical and commercial benefts lateral buckling made the bundle an ideal

Subsea 7 demonstrates the of bundle technology for new subsea solution for this high-temperature appli- efectiveness of pipeline bundle structures, as well as for rejuvenating cation; both potential design issues of solutions and a subsea depressor and extending existing ones. In all cases, high axial force and lateral buckling are coating the bundle’s interior with BuBi, a accommodated without need for expan- device in the North Sea. mechanically-bonded bimetal pipe devel- sion loops or buckle initiators.

By Meg Chesshyre oped by Butting, reduced overall cost At 160ºC, the Jasmine bundles are now compared with solid corrosion resistant being overtaken by Total’s West Franklin ubsea 7 is currently experi- alloy or clad pipe. bundle, which also consists of the larg- “ encing the busiest period of

Apache’s 5.5km-long Bacchus bundle est diameter carrier pipe at 56.64-in. in

S bundle design/installation ties the Bacchus drill center back to the the fortifed sections. The 6.7km single activity ever,” the company’s Bundle

Alpha Platform on the Forties oil feld, bundle connects the West Franklin

Design Manager, Martin Goodlad, the North Sea’s largest, which lies 170km wellhead platform to the Elgin well head revealed while presenting a paper at the east of Aberdeen. This was achieved platform. The use of a bundle meant that

Society of Petroleum Engineers’ (SPE)

Offshore Europe Oil and Gas Conference

Wick bundle fabrication site upgrade and Exhibition in Aberdeen last month.

Subsea 7 is currently investing over £5.5 million in refurbishing its pipeline bundle

A record eight bundles were installed fabrication site at Caithness, Scotland. Established in 1978, the fabrication site is throughout 2011-2012, with eight more located six miles north of Wick, Caithness in the North of Scotland. The site runs confrmed installations to be completed 7.8km inland, covering a total area in excess of 300,000sq m and has a sheltered by mid-2015, bringing the total number bay in which to launch the pipeline bundles. The refurbishment program will be of bundles installed over the last 35 carried out in two phases. It includes new, state-of-the-art equipment for fve fring years to more than 70. He added that a lines, a 230m extension to the main fabrication shop, and a new ofce and welfare number of the installed or currently in- complex at the landward end of the facility. The frst phase, which began in 2012 is design bundles are frsts for Subsea 7.

now complete, with the second phase of refurbishment is scheduled for completion

Using a number of North Sea case studies as examples, Goodlad discussed in 2014. •

November 2013 oedigital.com 40 040_OE1113_Subsea-1-pipelines.indd 40 10/28/13 1:46 AM

37

37

39

39