Page 43: of Offshore Engineer Magazine (Jan/Feb 2014)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2014 Offshore Engineer Magazine

Fig. 1: Sandvik super-duplex tubing.

Pitting and corrosion comparison austenitic-ferritic steel, organic acids, to compare

EPIC containing chloride have demonstrated it to high-alloy austen-

SAF 2507, which has a pit- 80

CPT (°C) (176) that tubing made from ASTM 316L has a itic stainless steels and ting resistance equivalent 70 service life shorter than ? ve years and, in nickel alloys in topside (PRE) value of 42.5, due to

CCT (°C) (158) some cases, less than one year. applications. its chemical composition 60

Testing over two years

This was based on ? eld trials con- of 25% Chromium (Cr), (140) to compare corrosion ducted in tropical waters by Shell, 4% Mo, 7% Nickel (Ni) 50 (122) rates of ASTM 316L and

Swagelok, and BP, and laboratory testing and 0.3% Nitrogen (N), 40

SAF 2507 was performed by Sandvik. compared to other steels (104) in 80% acetic acid, with

Operational experience in tropical (see Table 1). The 4% Mo 30

Temperature °C (°F) (86) 2000 ppm chloride ions at waters, such as the Gulf of Guinea and the gives it performance levels 20 90°C (194°F). The results

Gulf of Mexico, has mirrored test results, comparable to 6% Mo aus- (68) showed ASTM 316L has with ASTM 316L tubing service life seen tenitic stainless steels like 10 a corrosion rate of up to at less than ? ve years. In some extreme 254 SMO and AL-6XN.

(50) 1mm/year in such condi- cases, it can be less than one year. SAF 2507 was designed 6Mo+N 25 Cr 6Mo+N Sandvik 25 Cr 904L Sandvik 904L 25 Cr 904L Sandvik 6Mo+N SandvikSandvikSandvik

TM TM * tions, compared with

One ASTM 316L test sample on a ? oat- for highly corrosive con-

Duplex SAF 2205 austenitic SAF 2507 *25Cr-3Mo- .2N roughly 0.01mm/year on ing production, storage and of? oading ditions and chloride-bear-

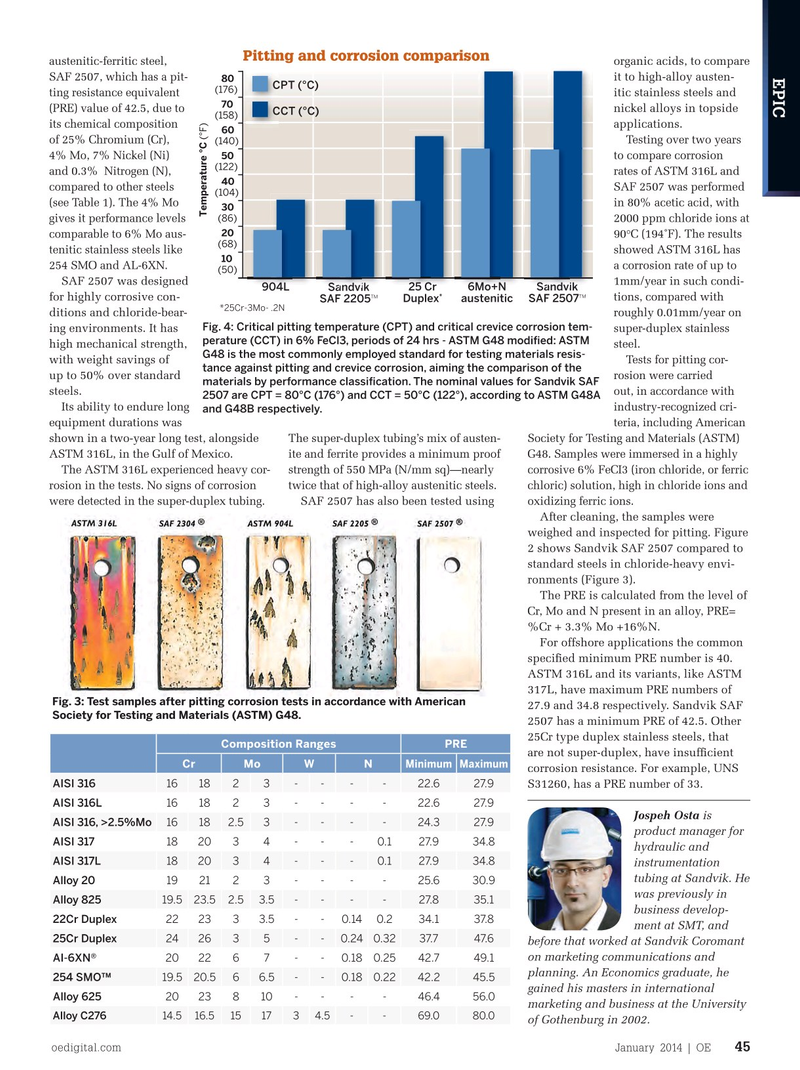

Fig. 4: Critical pitting temperature (CPT) and critical crevice corrosion tem- super-duplex stainless unit in the Gulf of Guinea showed severe ing environments. It has perature (CCT) in 6% FeCl3, periods of 24 hrs - ASTM G48 modi? ed: ASTM steel. signs of corrosion in small diameter high mechanical strength,

G48 is the most commonly employed standard for testing materials resis-

Tests for pitting cor- tubing in several locations in the topside with weight savings of tance against pitting and crevice corrosion, aiming the comparison of the rosion were carried facilities, less than a year after the unit up to 50% over standard materials by performance classi? cation. The nominal values for Sandvik SAF out, in accordance with was moored in place. Low levels of steels. 2507 are CPT = 80°C (176°) and CCT = 50°C (122°), according to ASTM G48A industry-recognized cri-

Molybdenum (Mo) in ASTM 316L steels Its ability to endure long and G48B respectively.

teria, including American was a contributing factor. equipment durations was

The super-duplex tubing’s mix of austen-

Society for Testing and Materials (ASTM)

This has serious implications, not shown in a two-year long test, alongside ite and ferrite provides a minimum proof

G48. Samples were immersed in a highly least the potential for accidents, causing ASTM 316L, in the Gulf of Mexico.

The ASTM 316L experienced heavy cor- strength of 550 MPa (N/mm sq)—nearly corrosive 6% FeCI3 (iron chloride, or ferric injury, or worse, due to sudden failures, rosion in the tests. No signs of corrosion twice that of high-alloy austenitic steels. chloric) solution, high in chloride ions and as well as the potential serious damage to were detected in the super-duplex tubing. oxidizing ferric ions. the platforms. SAF 2507 has also been tested using

In topside process systems—consisting After cleaning, the samples were of various vessels, heat exchangers, sepa- weighed and inspected for pitting. Figure rators and compressors—poor equipment 2 shows Sandvik SAF 2507 compared to life-spans pose a risk of sudden equip- standard steels in chloride-heavy envi- ment failure, and may even lead to costly ronments (Figure 3).

accidents. The PRE is calculated from the level of

Materials need to have resistance to Cr, Mo and N present in an alloy, PRE= stress corrosion cracking (SCC), pitting, %Cr + 3.3% Mo +16%N.

and crevice corrosion in chloride-bearing For offshore applications the common environments, in order to be suitable for speci? ed minimum PRE number is 40. hydraulic and instrumentation tubing ASTM 316L and its variants, like ASTM applications on offshore platforms. 317L, have maximum PRE numbers of

Fig. 3: Test samples after pitting corrosion tests in accordance with American

Some companies are turning to cor- 27.9 and 34.8 respectively. Sandvik SAF

Society for Testing and Materials (ASTM) G48.

rosion resistant alloys (CRAs), ranging 2507 has a minimum PRE of 42.5. Other from grade 13Cr and upwards, as well 25Cr type duplex stainless steels, that

Composition Ranges PRE as 6Mo austenitic steel types (containing are not super-duplex, have insuf? cient

Minimum Maximum

Cr Mo WN 6% Mo), such as 254 SMO, AL-6XN, and corrosion resistance. For example, UNS

AISI 316 16 1823----22.6 27.9 alloy 625. These cost more than super- S31260, has a PRE number of 33.

duplex steels, because they have higher

AISI 316L 16 1823----22.6 27.9 levels of Ni and Mo, and there is lower Jospeh Osta is

AISI 316, >2.5%Mo 16 182.53---- 24.3 27.9 market availability. product manager for

AISI 317 18 20 34--- 0.1 27.9 34.8

An alternative to CRAs are super- hydraulic and

AISI 317L 18 20 34--- 0.1 27.9 34.8 duplex steels, which have higher instrumentation strength, enabling a reduction in wall tubing at Sandvik. He

Alloy 20 19 2123---- 25.6 30.9 thickness of tubes and pipes in hydraulic was previously in

Alloy 825 19.5 23.5 2.5 3.5 ---- 27.8 35.1 and instrumentation systems, reducing business develop- 22Cr Duplex 22 23 3 3.5 -- 0.14 0.2 34.1 37.8 cost and weight. ment at SMT, and 25Cr Duplex 24 26 35-- 0.24 0.32 37.747.6

Sandvik has developed a super-duplex before that worked at Sandvik Coromant on marketing communications and

AI-6XN® 20 2267--0.180.2542.7 49.1

Fig. 2: ASTM 316L stainless steel and SAF planning. An Economics graduate, he 2507 super-duplex tubing, installed side 254 SMO™ 19.520.5 6 6.5 --0.180.2242.245.5 gained his masters in international by side, with the ASTM 316 tubing showing

Alloy 625 20 23 8 10 ---- 46.4 56.0 marketing and business at the University extensive corrosion and the super-duplex

Alloy C276 14.5 16.5 15 17 3 4.5 -- 69.080.0 tubing showing none. of Gothenburg in 2002.

oedigital.com January 2014 | OE 45 044_OE0114_EPIC1.indd 45 12/19/13 5:28 PM

42

42

44

44