Page 112: of Offshore Engineer Magazine (May/Jun 2014)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2014 Offshore Engineer Magazine

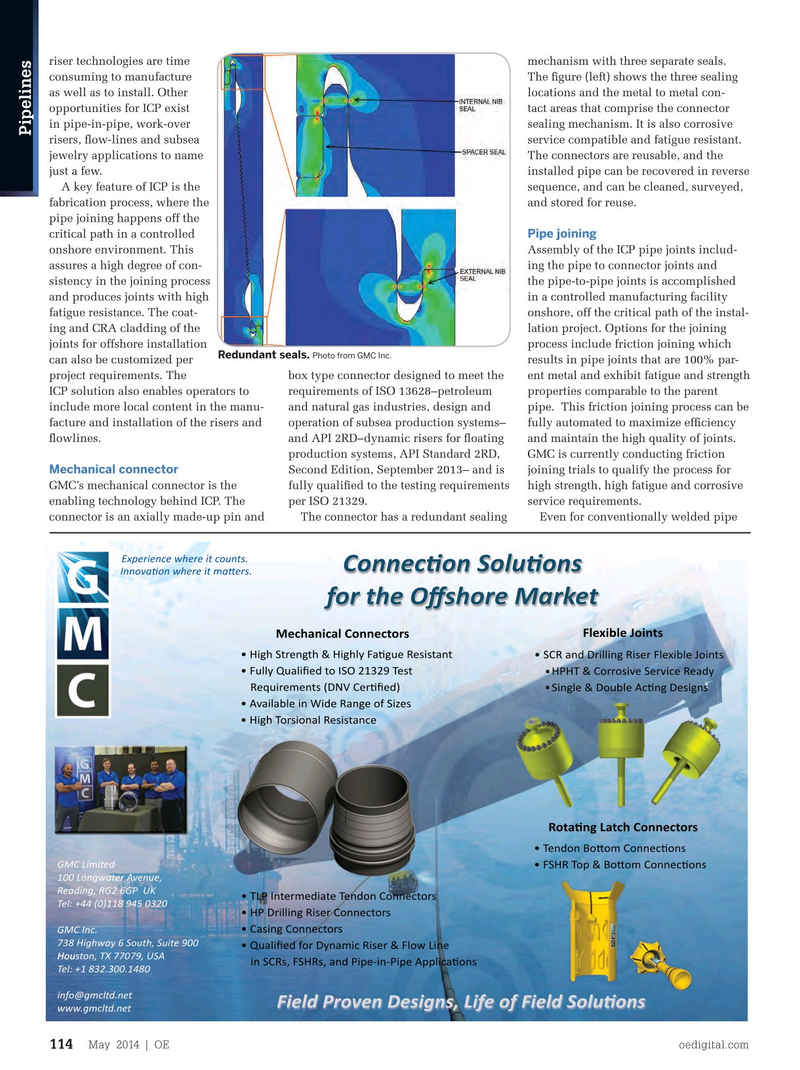

riser technologies are time mechanism with three separate seals. consuming to manufacture The fgure (left) shows the three sealing as well as to install. Other locations and the metal to metal con- opportunities for ICP exist tact areas that comprise the connector in pipe-in-pipe, work-over sealing mechanism. It is also corrosive

Pipelines risers, fow-lines and subsea service compatible and fatigue resistant. jewelry applications to name The connectors are reusable, and the just a few. installed pipe can be recovered in reverse

A key feature of ICP is the sequence, and can be cleaned, surveyed, fabrication process, where the and stored for reuse.

pipe joining happens off the

Pipe joining critical path in a controlled onshore environment. This Assembly of the ICP pipe joints includ- assures a high degree of con- ing the pipe to connector joints and sistency in the joining process the pipe-to-pipe joints is accomplished and produces joints with high in a controlled manufacturing facility fatigue resistance. The coat- onshore, off the critical path of the instal- ing and CRA cladding of the lation project. Options for the joining joints for offshore installation process include friction joining which

Redundant seals. Photo from GMC Inc.

can also be customized per results in pipe joints that are 100% par- project requirements. The box type connector designed to meet the ent metal and exhibit fatigue and strength

ICP solution also enables operators to requirements of ISO 13628–petroleum properties comparable to the parent include more local content in the manu- and natural gas industries, design and pipe. This friction joining process can be facture and installation of the risers and operation of subsea production systems– fully automated to maximize effciency fowlines. and API 2RD–dynamic risers for foating and maintain the high quality of joints. production systems, API Standard 2RD, GMC is currently conducting friction

Mechanical connector Second Edition, September 2013– and is joining trials to qualify the process for

GMC’s mechanical connector is the fully qualifed to the testing requirements high strength, high fatigue and corrosive enabling technology behind ICP. The per ISO 21329. service requirements. connector is an axially made-up pin and The connector has a redundant sealing Even for conventionally welded pipe

Experience where it counts.

Conneccon Solucons Innovaaon where it maaers.

for the O?shore Market

Mechanical Connectors Flexible Joints • High Strength & Highly Faague Resistant • SCR and Drilling Riser Flexible Joints • Fully Quali?ed to ISO 21329 Test HPHT & Corrosive Service Ready Requirements (DNV Cera?ed) Single & Double Acang Designs • Available in Wide Range of Sizes • High Torsional Resistance

Rotaang Latch Connectors • Tendon Booom Connecaons

GMC Limited • FSHR Top & Booom Connecaons 100 Longwater Avenue,

Reading, RG2 6GP UK • TLP Intermediate Tendon Connectors

Tel: +44 (0)118 945 0320 • HP Drilling Riser Connectors • Casing Connectors

GMC Inc.

738 Highway 6 South, Suite 900 • Quali?ed for Dynamic Riser & Flow Line

Hou Houston, TX 77079, USA in SCRs, FSHRs, and Pipe-in-Pipe Applicaaons

Tel: +1 832.300.1480 [email protected]

Field Proven Designs, Life of Field Solucons www.gmcltd.net

May 2014 | OE oedigital.com 114 112_OE0514_Pipelines2_GMC.indd 114 4/19/14 9:59 AM

111

111

113

113