Page 113: of Offshore Engineer Magazine (May/Jun 2014)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2014 Offshore Engineer Magazine

Pipelines joints, the ability to complete of the risers and fowlines. This results

Normalized project cost – all welds in a controlled in project costs that can easily be double

ICP versus other environment, including the the cost calculated by simply multiplying

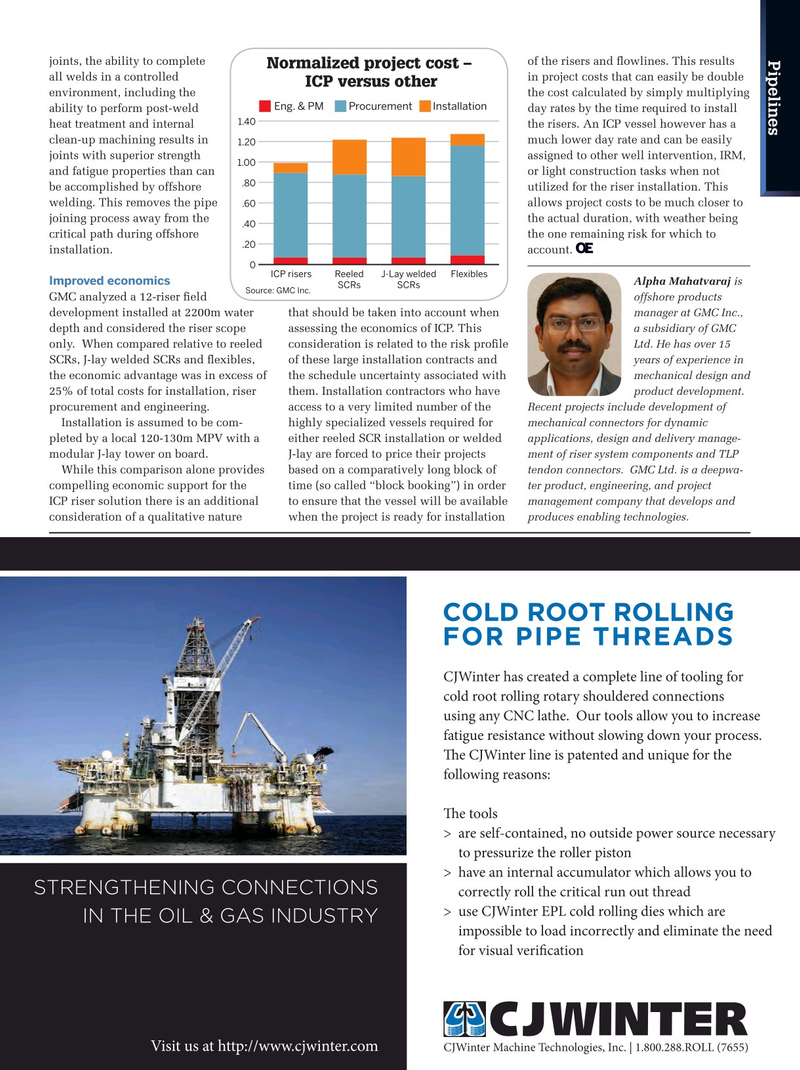

Eng. & PMProcurementInstallation ability to perform post-weld day rates by the time required to install 1.40 heat treatment and internal the risers. An ICP vessel however has a clean-up machining results in much lower day rate and can be easily 1.20 joints with superior strength assigned to other well intervention, IRM, 1.00 and fatigue properties than can or light construction tasks when not .80 be accomplished by offshore utilized for the riser installation. This welding. This removes the pipe allows project costs to be much closer to .60 joining process away from the the actual duration, with weather being .40 critical path during offshore the one remaining risk for which to .20 installation. account. 0

ICP risersReeled J-Lay welded Flexibles

Improved economics Alpha Mahatvaraj is

SCRs SCRs

Source: GMC Inc.

offshore products

GMC analyzed a 12-riser feld manager at GMC Inc., development installed at 2200m water that should be taken into account when a subsidiary of GMC depth and considered the riser scope assessing the economics of ICP. This

Ltd. He has over 15 only. When compared relative to reeled consideration is related to the risk profle years of experience in

SCRs, J-lay welded SCRs and fexibles, of these large installation contracts and mechanical design and the economic advantage was in excess of the schedule uncertainty associated with product development. 25% of total costs for installation, riser them. Installation contractors who have

Recent projects include development of procurement and engineering. access to a very limited number of the mechanical connectors for dynamic

Installation is assumed to be com- highly specialized vessels required for applications, design and delivery manage- pleted by a local 120-130m MPV with a either reeled SCR installation or welded ment of riser system components and TLP modular J-lay tower on board. J-lay are forced to price their projects tendon connectors. GMC Ltd. is a deepwa-

While this comparison alone provides based on a comparatively long block of ter product, engineering, and project compelling economic support for the time (so called “block booking”) in order management company that develops and

ICP riser solution there is an additional to ensure that the vessel will be available produces enabling technologies.

consideration of a qualitative nature when the project is ready for installation 112_OE0514_Pipelines2_GMC.indd 115 4/19/14 9:59 AM

112

112

114

114