Page 30: of Offshore Engineer Magazine (Jul/Aug 2014)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2014 Offshore Engineer Magazine

REMOTE TECHNOLOGIES

Once data is collected, the

WirelessHART gateway commu- nicates with SKF’s wireless sensor device manager software. Data can then be automatically exported into

SKF’s comprehensive diagnostic and analytic software package, where a maintenance engineer can analyze the data and determine a course of action. In parallel, the

WirelessHART gateway can also send applicable data directly to the process control system for visual- ization and trending by operators.

Conclusion

Wireless systems will change the way we approach machine condi-

WirelessHART Gateway

Hazardous area tion parameter data collection.

Wireless sensors will result in much more data being acquired and, therefore, a challenge of how

LAN Network to analyze and manage additional data. Data reduction techniques and decision support systems have been developed to cope with this issue, thus preserving the beneft of new wireless technologies and

SKF @ptitude Analyst / Process and automation control ensuring it is supportive of mainte-

Wireless Sensor Device Manager software nance strategy refnements.

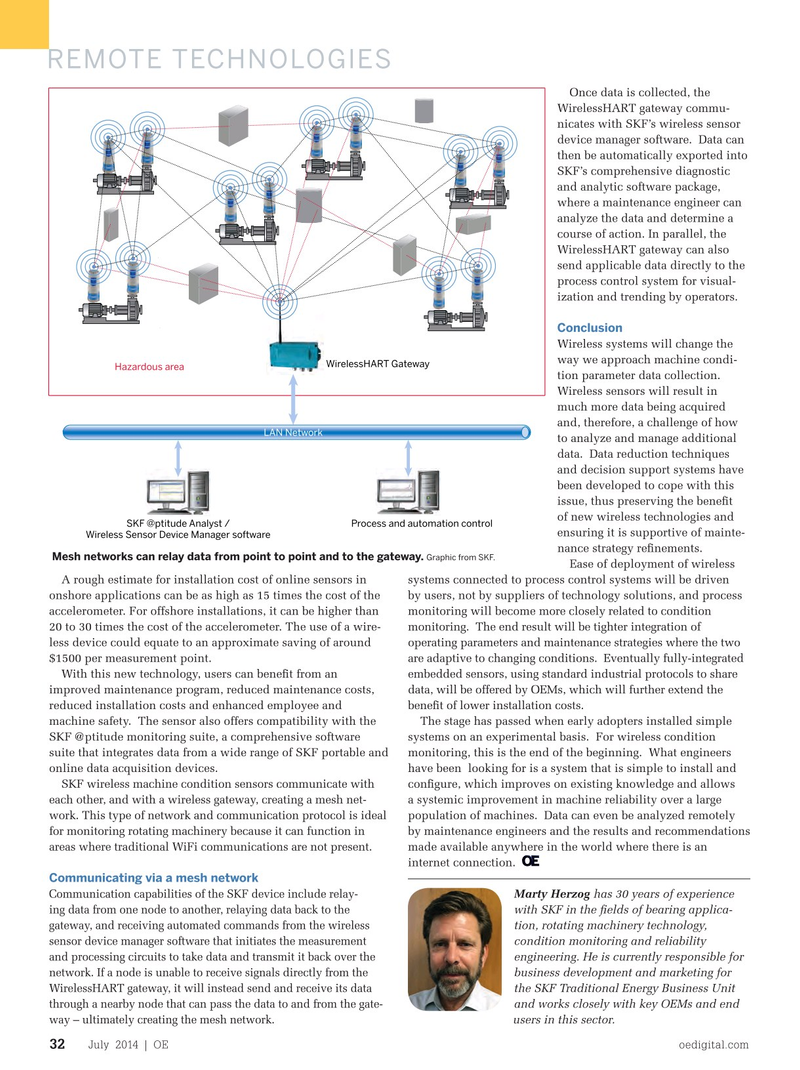

Mesh networks can relay data from point to point and to the gateway. Graphic from SKF.

Ease of deployment of wireless

A rough estimate for installation cost of online sensors in systems connected to process control systems will be driven onshore applications can be as high as 15 times the cost of the by users, not by suppliers of technology solutions, and process accelerometer. For offshore installations, it can be higher than monitoring will become more closely related to condition 20 to 30 times the cost of the accelerometer. The use of a wire- monitoring. The end result will be tighter integration of less device could equate to an approximate saving of around operating parameters and maintenance strategies where the two $1500 per measurement point. are adaptive to changing conditions. Eventually fully-integrated

With this new technology, users can beneft from an embedded sensors, using standard industrial protocols to share improved maintenance program, reduced maintenance costs, data, will be offered by OEMs, which will further extend the reduced installation costs and enhanced employee and beneft of lower installation costs. machine safety. The sensor also offers compatibility with the The stage has passed when early adopters installed simple

SKF @ ptitude monitoring suite, a comprehensive software systems on an experimental basis. For wireless condition suite that integrates data from a wide range of SKF portable and monitoring, this is the end of the beginning. What engineers online data acquisition devices. have been looking for is a system that is simple to install and

SKF wireless machine condition sensors communicate with confgure, which improves on existing knowledge and allows each other, and with a wireless gateway, creating a mesh net- a systemic improvement in machine reliability over a large work. This type of network and communication protocol is ideal population of machines. Data can even be analyzed remotely for monitoring rotating machinery because it can function in by maintenance engineers and the results and recommendations areas where traditional WiFi communications are not present. made available anywhere in the world where there is an internet connection.

Communicating via a mesh network

Marty Herzog has 30 years of experience

Communication capabilities of the SKF device include relay- with SKF in the felds of bearing applica- ing data from one node to another, relaying data back to the gateway, and receiving automated commands from the wireless tion, rotating machinery technology, sensor device manager software that initiates the measurement condition monitoring and reliability and processing circuits to take data and transmit it back over the engineering. He is currently responsible for network. If a node is unable to receive signals directly from the business development and marketing for

WirelessHART gateway, it will instead send and receive its data the SKF Traditional Energy Business Unit through a nearby node that can pass the data to and from the gate- and works closely with key OEMs and end way – ultimately creating the mesh network.

users in this sector.

July 2014 | OE oedigital.com 32 030_OE0714_Feature2_SFK.indd 32 6/20/14 11:47 AM

29

29

31

31