Page 66: of Offshore Engineer Magazine (Aug/Sep 2014)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2014 Offshore Engineer Magazine

EPIC-4-Fig1 ENI’s Goliat FPSO. Photo from ENI.

EPIC-4-(NOT SURE IF THESE are GOOD ENOUGH.. I was using the iphone…)

EPIC-4-No fg 4

EPIC-4-[copy] next year. The simulations,

EPIC carried out in three phases during design, uncovered blind zones and challeng- ing lift scenarios that were then able to be changed or mitigated.

Torbjorn Alstad, SMSC’s chief marketing offcer, told the conference that using the actual design models, SMSC devel- oped simulator models and performed simulated operations for Goliat’s two cranes. This meant blind zones, where the crane operator would not be able to see, lifting corridors, and exhaust zones could be modeled and assessed and changes made to the design before construction started. Certain areas were strengthened, due to being in potential risk of being knocked.

Also, which crane corridors would be best utilized for specifc tasks were identifed.

From simulation to WRR

The changes also meant improve- ments in the overall design, because it identifed extra lay-down area. Where

Ofshore lifting combines heavy ofshore assets with detailed hen it comes to offshore changes could not be made to mitigate analysis and product care. Elaine Maslin found out more at the lifting, it is usually the an identifed problem, alternatives

W heavy installation vessels were suggested and adopted, such

North Sea Ofshore Crane and Lifting Conference.

and barges that get most of the attention. as focusing on the communication

But, there is much more to offshore between the crane operator and deck lifting operations, from lift modeling, personnel. “The projects have uncovered blind and crane design and fabrication, to rope zones and challenging lifts at a very manufacture and certifcation, and rope early stage, enabling us to make neces- lubrication and testing. These factors sary changes. It was the frst time we stretch right through project life-cycles had done something like this and I and the supply chain, from rope and believe more companies should do this crane manufacture to design integration type of thing, it would save them a lot and operations. of money,” Alstad says.

Norway’s Ship Modelling &

Simulation Centre (SMSC) demonstrated

Slings how knowing how a rope or crane will perform will be benefcial during front Computer modeling could potentially be end engineering and design, at the used to calculate break loads, suggests

North Sea Offshore Crane and Lifting Jan-Peter Breedeveld, engineering direc-

Conference, held in Aberdeen in late tor, Seaway Heavy Lifting, Netherlands.

April. He suggests that few know the actual break load and failure modes in large

Simulation diameter cable laid slings, which

SMSC used a crane simulator to improve the crane integration on ENI’s

Goliat FPSO, which is due to start pro-

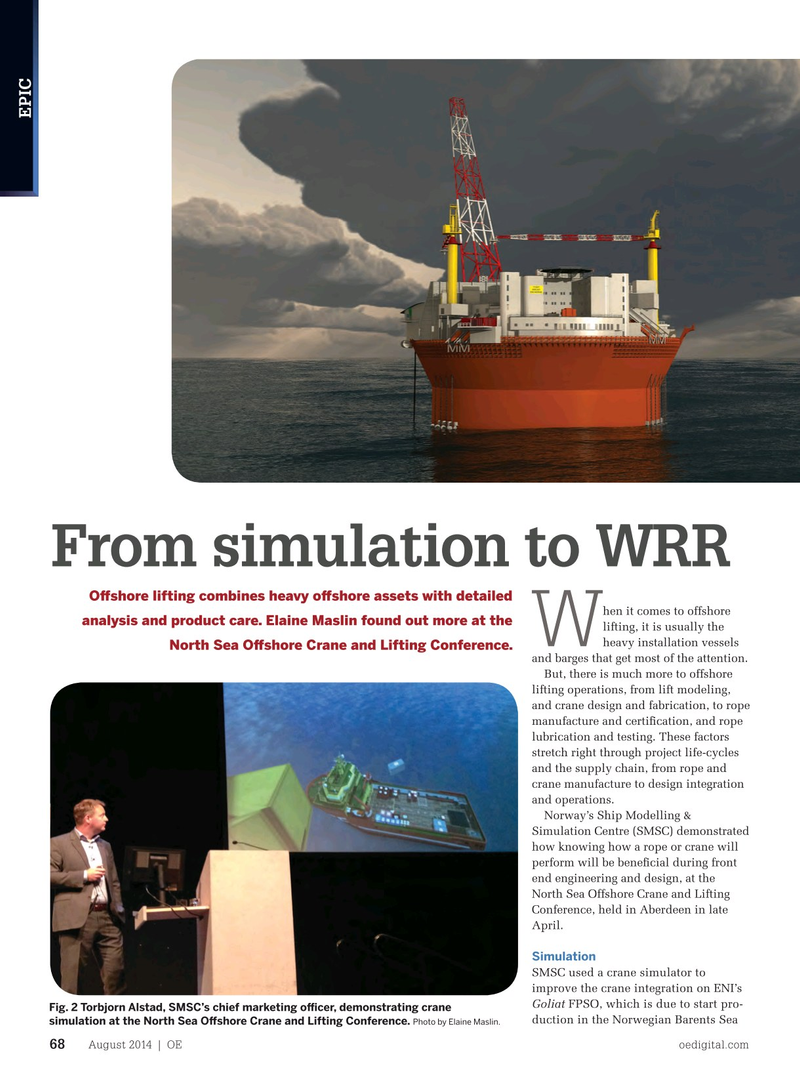

Fig. 2 Torbjorn Alstad, SMSC’s chief marketing ofcer, demonstrating crane duction in the Norwegian Barents Sea simulation at the North Sea Ofshore Crane and Lifting Conference.

Photo by Elaine Maslin.

August 2014 | OE oedigital.com 68 000_OE0814_EPIC4_OffshoreLift.indd 68 7/22/14 10:19 PM

65

65

67

67