Page 58: of Offshore Engineer Magazine (Sep/Oct 2014)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2014 Offshore Engineer Magazine

controller, which is a real-time super- SWOB set point to deliver the desired visory control engine that utilizes rig DWOB determined by the drilling equipment to deliver the desired DWOB. program plan or optimization applica-

Well construction applications tions. Auto driller parameters such as • The add-on does more than just RPM and differential pressure can also

Drilling

Closed-loop enhance control; it enables data visu- be recommended by the optimization alization and software applications. applications.

3.

Current applications deliver rate of The autodriller receives the SWOB penetration (ROP) optimization, risk set point as a request, analyzes it in the drilling management, dynamics mitigation context of its current operational state (SoftSpeed II stick-slip service), and and safety case, and makes a decision

An in-depth look at NOV’s steering optimization. mud density (ECD) management, and whether to implement the requested

The data ? ow and automation process is mechanical speci? c energy parameter SWOB set point or not.

closed-loop drilling automation as follows: optimization. The NOV DDS optimization team has system, which could help develop 1. Data from the BHA and drillstring are

In NOV’s system, downhole data is already demonstrated consistent ROP transmitted to the surface via the telemetry measured by a downhole drilling dynam- improvements of 20-30% with occasional

North Sea and Arctic assets. network and combined with surface data ics sub and is then transmitted to the improvements of 100% (Pink et al. 2011). in the rig’s control system. The data is vali- surface via wired drillpipe. Surface and utomation is a growing force in “Drilling automation improves drill- dated and analyzed on a ? xed time interval. downhole acquired data is interpreted the offshore oil and gas indus- ing stability, reduces risk, and increases

A 2.

Control logic computes the required and analyzed by software applications, try. Its potential to increase ROP. These improvements will also help safety, optimize operations, improve and commands are then distributed to quality, and reduce risk is a strong driver the rig’s control system to adjust the for an industry with ever-rising costs. appropriate machine functions. The

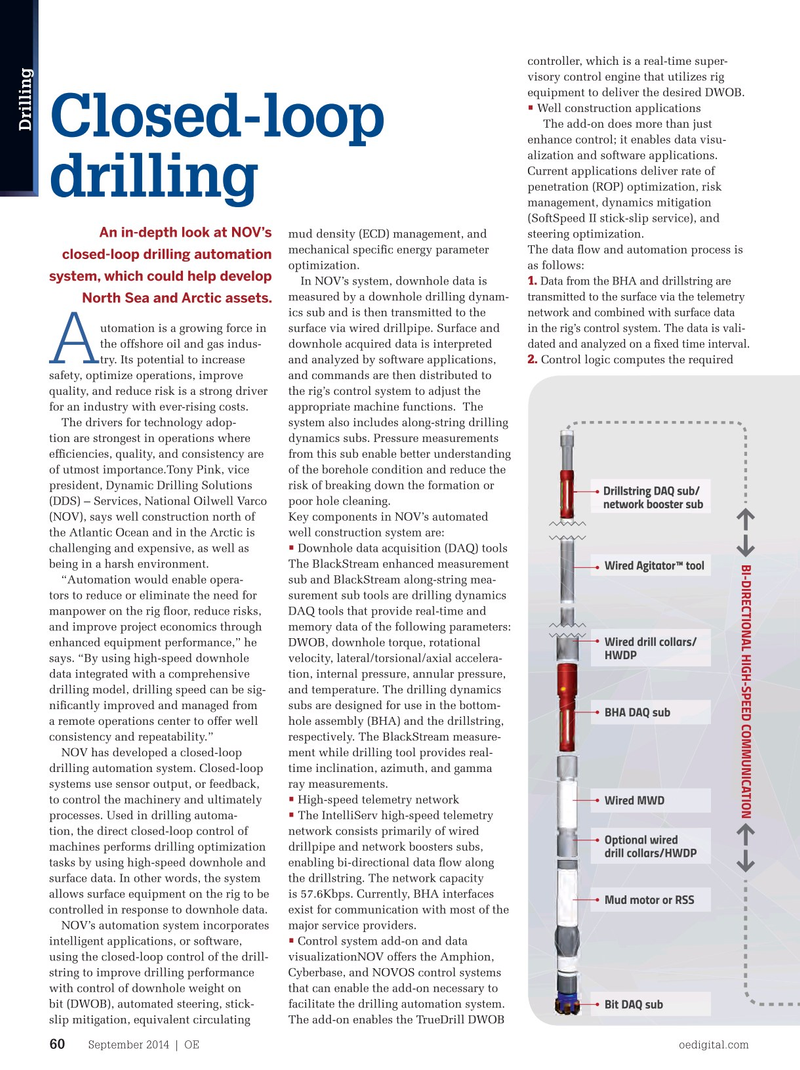

The drivers for technology adop- system also includes along-string drilling tion are strongest in operations where dynamics subs. Pressure measurements ef? ciencies, quality, and consistency are from this sub enable better understanding of utmost importance.Tony Pink, vice of the borehole condition and reduce the president, Dynamic Drilling Solutions risk of breaking down the formation or (DDS) – Services, National Oilwell Varco poor hole cleaning. (NOV), says well construction north of Key components in NOV’s automated the Atlantic Ocean and in the Arctic is well construction system are: • challenging and expensive, as well as Downhole data acquisition (DAQ) tools being in a harsh environment. The BlackStream enhanced measurement “Automation would enable opera- sub and BlackStream along-string mea- tors to reduce or eliminate the need for surement sub tools are drilling dynamics manpower on the rig ? oor, reduce risks, DAQ tools that provide real-time and and improve project economics through memory data of the following parameters: enhanced equipment performance,” he DWOB, downhole torque, rotational says. “By using high-speed downhole velocity, lateral/torsional/axial accelera- data integrated with a comprehensive tion, internal pressure, annular pressure, drilling model, drilling speed can be sig- and temperature. The drilling dynamics ni? cantly improved and managed from subs are designed for use in the bottom- a remote operations center to offer well hole assembly (BHA) and the drillstring, consistency and repeatability.” respectively. The BlackStream measure-

NOV has developed a closed-loop ment while drilling tool provides real- drilling automation system. Closed-loop time inclination, azimuth, and gamma systems use sensor output, or feedback, ray measurements. • to control the machinery and ultimately High-speed telemetry network • processes. Used in drilling automa- The IntelliServ high-speed telemetry tion, the direct closed-loop control of network consists primarily of wired machines performs drilling optimization drillpipe and network boosters subs, tasks by using high-speed downhole and enabling bi-directional data ? ow along surface data. In other words, the system the drillstring. The network capacity allows surface equipment on the rig to be is 57.6Kbps. Currently, BHA interfaces controlled in response to downhole data. exist for communication with most of the

NOV’s automation system incorporates major service providers.

• intelligent applications, or software, Control system add-on and data using the closed-loop control of the drill- visualizationNOV offers the Amphion, string to improve drilling performance Cyberbase, and NOVOS control systems with control of downhole weight on that can enable the add-on necessary to bit (DWOB), automated steering, stick- facilitate the drilling automation system. slip mitigation, equivalent circulating The add-on enables the TrueDrill DWOB

September 2014 | OE oedigital.com 60 060_OE0914_D&C4_NOV.indd 60 8/21/14 4:49 PM

57

57

59

59