Page 66: of Offshore Engineer Magazine (Sep/Oct 2014)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2014 Offshore Engineer Magazine

real-time calculation of gained or lost mud volumes, which impacts the time required for effective decision making.

Because of the accuracy and reliability of this method, drilling procedures have

EyebrowProduction been adapted that reduce the number of fow checks required at each connec- tion. After the various successful event detections, the decision was made not to perform any fow checks without prior detection by the processed differential fow out, which allows a saving of 10-15 min. at each connection.

This article was prepared based on SPE 158374, presented at the 2012 SPETT

Energy Conference and Exhibition held in

Port of Spain, Trinidad, June 11-13, 2012.

Scott Hilliard, Lead Drilling Engineer,

Statoil, is a licensed Professional Engineer with six years of experience planning and drilling deepwater exploration wells in the

Gulf of Mexico. Scott graduated from the

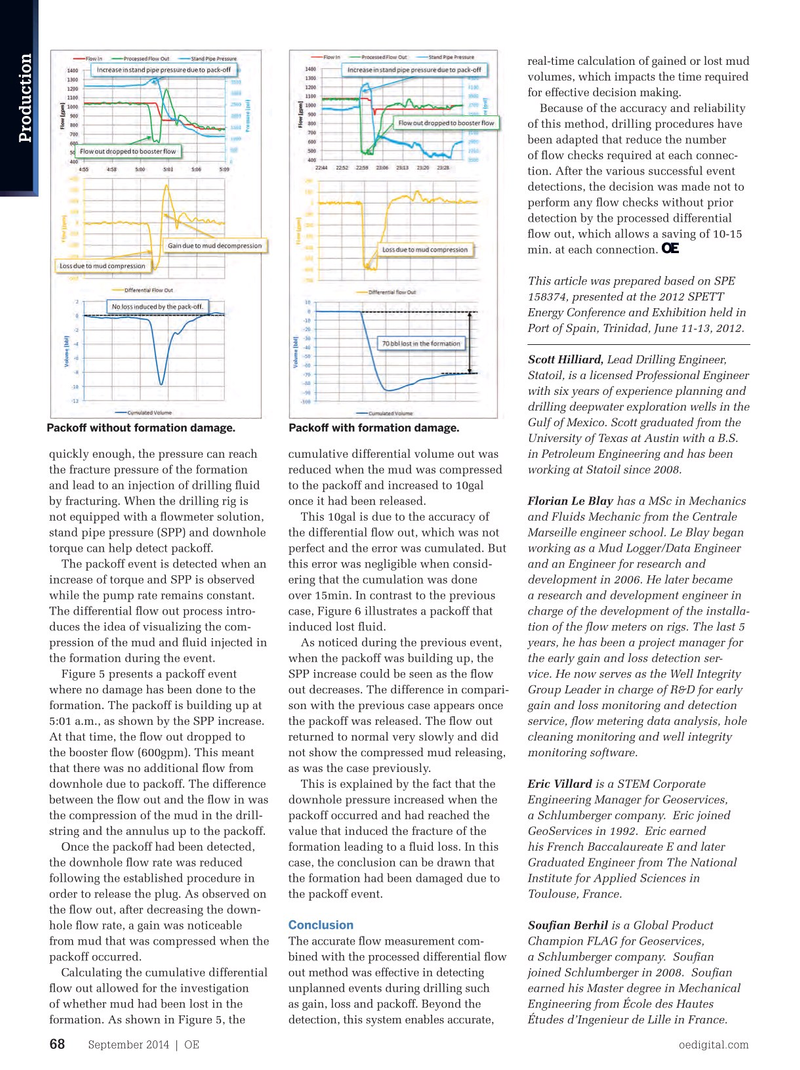

Packof without formation damage.Packof with formation damage.

University of Texas at Austin with a B.S. quickly enough, the pressure can reach cumulative differential volume out was in Petroleum Engineering and has been the fracture pressure of the formation reduced when the mud was compressed working at Statoil since 2008. and lead to an injection of drilling fuid to the packoff and increased to 10gal by fracturing. When the drilling rig is once it had been released. Florian Le Blay has a MSc in Mechanics not equipped with a fowmeter solution, This 10gal is due to the accuracy of and Fluids Mechanic from the Centrale stand pipe pressure (SPP) and downhole the differential fow out, which was not Marseille engineer school. Le Blay began torque can help detect packoff. perfect and the error was cumulated. But working as a Mud Logger/Data Engineer

The packoff event is detected when an this error was negligible when consid- and an Engineer for research and increase of torque and SPP is observed ering that the cumulation was done development in 2006. He later became while the pump rate remains constant. over 15min. In contrast to the previous a research and development engineer in

The differential fow out process intro- case, Figure 6 illustrates a packoff that charge of the development of the installa- duces the idea of visualizing the com- induced lost fuid. tion of the fow meters on rigs. The last 5 pression of the mud and fuid injected in As noticed during the previous event, years, he has been a project manager for the formation during the event. when the packoff was building up, the the early gain and loss detection ser-

Figure 5 presents a packoff event SPP increase could be seen as the fow vice. He now serves as the Well Integrity where no damage has been done to the out decreases. The difference in compari- Group Leader in charge of R&D for early formation. The packoff is building up at son with the previous case appears once gain and loss monitoring and detection 5:01 a.m., as shown by the SPP increase. the packoff was released. The fow out service, fow metering data analysis, hole

At that time, the fow out dropped to returned to normal very slowly and did cleaning monitoring and well integrity the booster fow (600gpm). This meant not show the compressed mud releasing, monitoring software. that there was no additional fow from as was the case previously. downhole due to packoff. The difference This is explained by the fact that the Eric Villard is a STEM Corporate between the fow out and the fow in was downhole pressure increased when the Engineering Manager for Geoservices, the compression of the mud in the drill- packoff occurred and had reached the a Schlumberger company. Eric joined string and the annulus up to the packoff. value that induced the fracture of the GeoServices in 1992. Eric earned

Once the packoff had been detected, formation leading to a fuid loss. In this his French Baccalaureate E and later the downhole fow rate was reduced case, the conclusion can be drawn that Graduated Engineer from The National following the established procedure in the formation had been damaged due to Institute for Applied Sciences in order to release the plug. As observed on the packoff event. Toulouse, France. the fow out, after decreasing the down-

Conclusion hole fow rate, a gain was noticeable Soufan Berhil is a Global Product from mud that was compressed when the The accurate fow measurement com- Champion FLAG for Geoservices, packoff occurred. bined with the processed differential fow a Schlumberger company. Soufan

Calculating the cumulative differential out method was effective in detecting joined Schlumberger in 2008. Soufan fow out allowed for the investigation unplanned events during drilling such earned his Master degree in Mechanical of whether mud had been lost in the as gain, loss and packoff. Beyond the Engineering from École des Hautes formation. As shown in Figure 5, the detection, this system enables accurate, Études d’Ingenieur de Lille in France.

September 2014 | OE oedigital.com 68 066_OE0914_ProdOps_2_SLB.indd 68 8/21/14 1:30 PM

65

65

67

67