Page 65: of Offshore Engineer Magazine (Sep/Oct 2014)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2014 Offshore Engineer Magazine

EyebrowProduction obtain well fow, an important factor for fow paddle, it would have been impos- the fow check, it should be included. monitoring. sible to detect the infux that occurred Because differential fow out is not infu-

Standard measurement methods cur- at 7 p.m. Even when the pumps are enced by any transfer and is calibrated rently being employed on rigs are mostly stopped, the signal from the fow paddle to compensate for this fow-back effect, achieved using a fow paddle and the is not clear enough to determine infux. the calculation of the gain volume is active volume. Measurements based on However, in examining differential fow done accurately in real time, as shown the fow paddle can be easily obtained, out, the wellbore obviously began fow- in Figure 4. This enables decisions to be but paddle reliability is low due to its ing at 7 p.m. made more quickly.

Figure 2 represents the active volume mechanical principle and the noisy

Packof complicatons monitoring. This method of gain/loss signal, especially on foating rigs where detection is accurate, but, as shown on heave is a signifcant factor. Moreover, Besides the infux, the packoff also the plot, the increase in the pit volume comparing the signal with pump fow can lead to undesirable consequences, is observed fve minutes after the gain rate also is not possible. The accuracy of including damage to the formation. was observed on the differential fow out. the measurement from the fow paddle Packoff occurs when a plug is formed

Considering that the well was fowing at is debatable. The fow paddle provides downhole, primarily at the stabilizer about 35gpm, a fve minute delay repre- fuid height measurement, but requires level. This leads to an increase of the sented more than four barrels, a signifcant an assumption of the fuid veloc- pressure on bottom as drilling mud amount when a gain is considered, espe- ity in any attempt to infer a fow rate. compresses. If the packoff is not released cially if the infux is gas. The delay was

Unfortunately, the fuid fow profle can explained by the fact that the pits were far change signifcantly with fuid properties from the bell nipple, after the gumbo box like density and rheology.

and the shakers, when the fow sensor was

The advanced measurement process in installed farther upstream.

this paper includes many factors that can infuence the measurement of actual fow Figure 3 highlights the effect of pipe including pump rate, pipe movement, movement. Once the gain was detected, mud compressibility effect, fow line fow the decision to stop drilling had been back and heave effect. made. When the basic differential fow

Differential fow out, which is the differ- is considered (fow out–fow in), the ence between actual fow out and theoreti- decrease of fow out can be seen. cal fow out, allows for accurate and quick

Performing only this calculation to

As part of the FLAG service, a Coriolis fowmeter installed in the return fowline calculation of the actual volume of the visualize gain or loss fow can lead to continuously measures the actual fow. Photo from Schlumberger.

infux or loss without being affected by pit the erroneous conclusion that infux has the electromagnetic sensor make it the stopped and that the drilling operation transfers that happen often during drilling.

best option for fow measurement, being can restart without risk. But the decrease

Early gain detection is the frst advan- restricted to conductive fuid, or water- of fow out is due to the steel volume of tage of using fow measurement at the fow

Fig. 3: Pipe movement compensation and base mud (WBM), made the Coriolis fow the drill string that was removed from the line. Detecting infux as early as possible is swab efect.

crucial to reducing volume and minimiz- sensor the preferred option because it well while pulling out of the hole. ing the risk of an uncontrolled event, or The differential fow out is compensat- works with any kind of drilling fuid.

spending time controlling the well. ing the steel volume, which demonstrates

However the Coriolis fow sensor was that the kick is not only occuring, but the rarely used because it required heavy

Case study kick is actually increasing due to the swab- installation and was available only in bing effect. The trend of differential fow a small 6in. size. The installed sensor Figures 1, 2 and 3 demonstrate real-time out is slightly different and highlights an requires a bypass setup. Its small size lim- data from a kick event on a sixth genera- increase of the well fow magnitude.

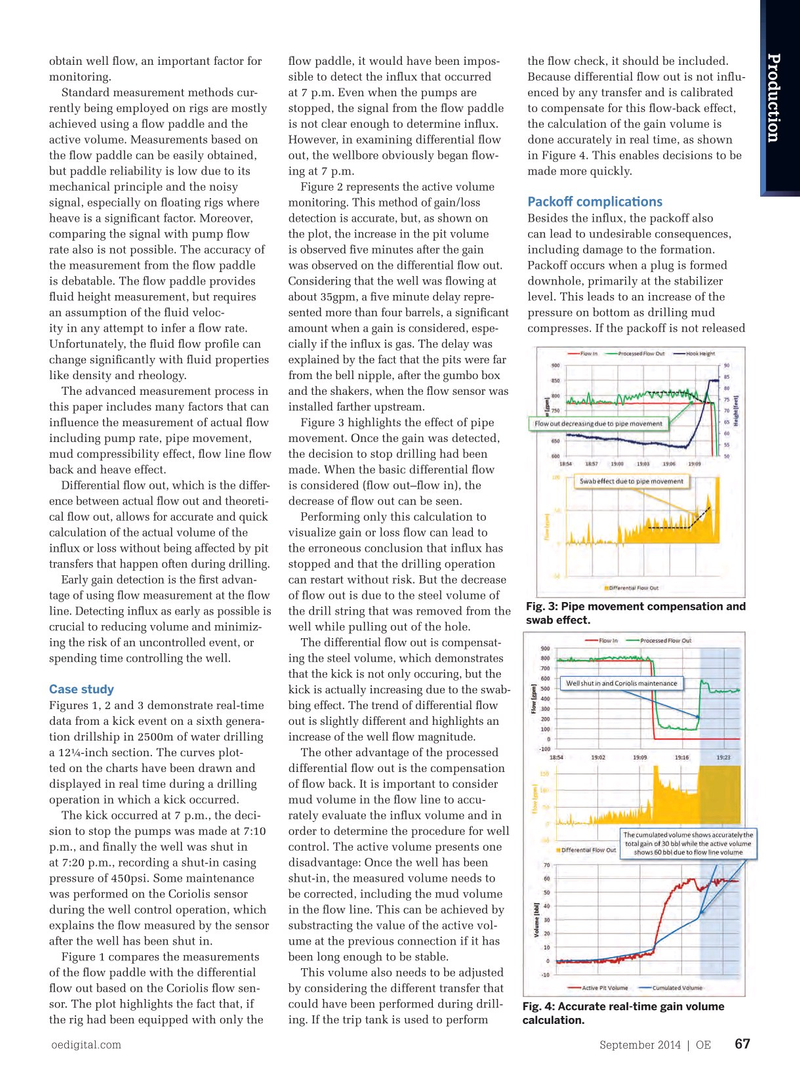

its the fow rate by inducing a signifcant tion drillship in 2500m of water drilling a 12¼-inch section. The curves plot- pressure drop that leads to a hydrostatic The other advantage of the processed ted on the charts have been drawn and head before the bypass. This hydrostatic differential fow out is the compensation displayed in real time during a drilling head reduces the fow rate. of fow back. It is important to consider

The introduction of larger Coriolis operation in which a kick occurred. mud volume in the fow line to accu- sensors in recent years

The kick occurred at 7 p.m., the deci- rately evaluate the infux volume and in has raised the limit of the sion to stop the pumps was made at 7:10 order to determine the procedure for well maximum fow rate. When p.m., and fnally the well was shut in control. The active volume presents one combined with an opti- at 7:20 p.m., recording a shut-in casing disadvantage: Once the well has been mized bypass design, these pressure of 450psi. Some maintenance shut-in, the measured volume needs to large sensors can be used at was performed on the Coriolis sensor be corrected, including the mud volume very high fow rates for all during the well control operation, which in the fow line. This can be achieved by drilling operations as long explains the fow measured by the sensor substracting the value of the active vol- as drilling fuid return is after the well has been shut in. ume at the previous connection if it has directed into the fow line.

Figure 1 compares the measurements been long enough to be stable. of the fow paddle with the differential This volume also needs to be adjusted

Measurement methods fow out based on the Coriolis fow sen- by considering the different transfer that sor. The plot highlights the fact that, if Accurate measurement of could have been performed during drill-

Fig. 4: Accurate real-time gain volume the rig had been equipped with only the return fow is required to ing. If the trip tank is used to perform calculation.

oedigital.com September 2014 | OE 67 066_OE0914_ProdOps_2_SLB.indd 67 8/21/14 1:29 PM

64

64

66

66