Page 40: of Offshore Engineer Magazine (Jan/Feb 2015)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2015 Offshore Engineer Magazine

failure (MTTF) data to support cost- saving decisions.

Most operators accept that certain well barrier component failures are inevitable and operational constraints may mean

Drilling

Benchmarking that they cannot be repaired immediately.

It can be necessary for wells with indi- vidual components not in full working order to continue to operate, provided reliability risk assessment indicates the risk level is acceptable. Of course, some types of operators to make data such as compo- failure call for the well to be shut-in and

The capability to benchmark the reliability of safety- nent reliability and failure rates avail- repaired immediately, but for the major- critical well barrier components against a global able externally. ity of non-critical failures, repairs are component test database will enable oil and gas operators

In addition to concerns over data scheduled to take place within a desig- con? dentiality, efforts to build such a nated timeframe, or when the opportu- to optimize asset performance, Ged Lunt says. database have tended to be limited to nity arises. single regions such as the North Sea, or Testing can actually reduce the lifetime during well workovers. ptimizing asset performance focused strongly on speci? c components of the equipment – especially an active

The performance of installed well remains a continuous challenge such as the SSSV. Previous systems have component that is opened and shut, each

O components must be totally predict- for oil and gas operators. A key also been badly structured and suffered cycle causing some amount of wear and able. Should a problem arise at any element in achieving this is selecting from poor quality of data or dif? culty of fatigue. given point in time, operators must be well equipment with reliable perfor- use or access. Given that it is necessary to close con? dent that they know how their mance. However, making the correct valves in order to test the leak rate

Better insight, better decisions well barrier components will respond. selection is far from simple; different across them, using risk-based analysis

Wood Group Intetech launched a global

For example, if they shut a subsurface equipment models may be more suited to determine that testing can be safely database of well performance data safety valve (SSSV), then they know to certain operating conditions. When performed less frequently, should extend called iQRA. This online quantita- with certainty that it’s going to close conditions are very challenging, well the lifetime of valves, as well as reducing tive reliability analysis tool provides and contain the well ? uids in the speci- designs may need to be adjusted to operating costs. operators with access to global well ? ed time.

allow for lower achievable reliability Access to this kind of reliability infor-

Getting accurate reliability ? gures for of particular equipment to maintain mation makes it possible for operators to and oil? eld component performance well barrier components requires access an acceptably low overall level of well identify where they have low reliability information, so operators can identify to a statistically signi? cant database. failure risk. A lot of considerations lie equipment or potentially a faulty compo- the highest performing well compo-

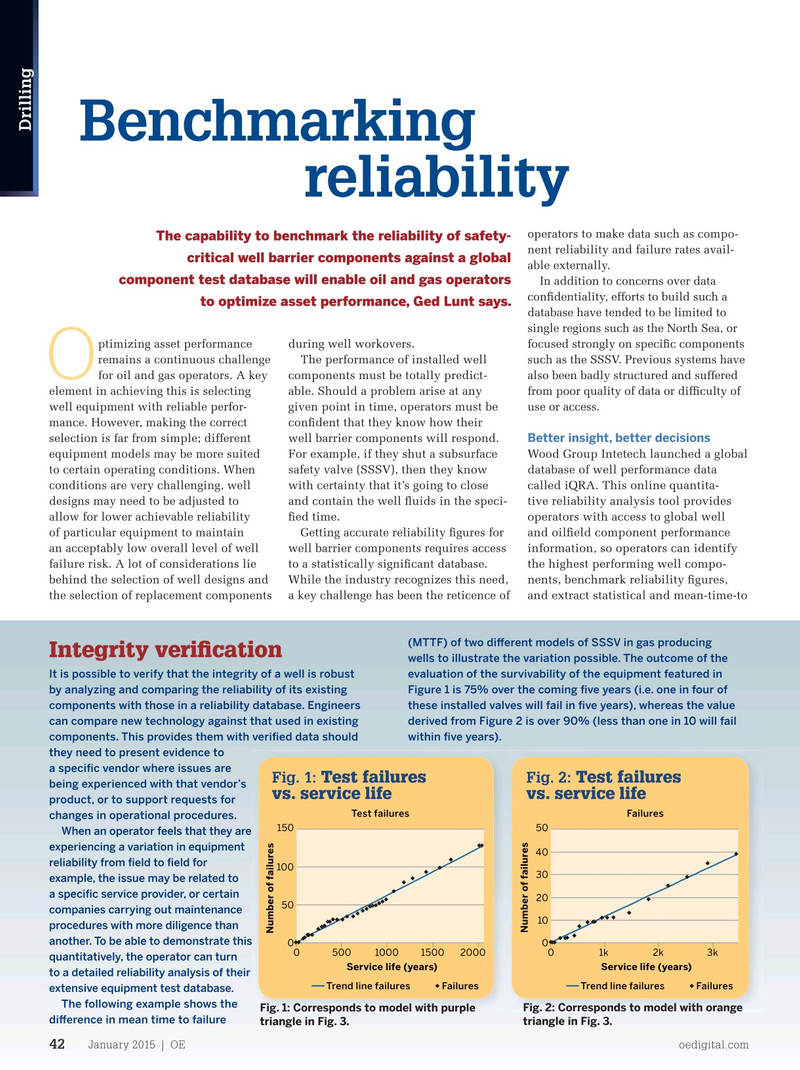

While the industry recognizes this need, behind the selection of well designs and nent, and pre-empt potential failures on nents, benchmark reliability ? gures, a key challenge has been the reticence of the selection of replacement components other wells by taking the opportunity to and extract statistical and mean-time-to (MTTF) of two di

39

39

41

41