Page 49: of Offshore Engineer Magazine (Jan/Feb 2015)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2015 Offshore Engineer Magazine

•

Other factors including low gas oil ratio for through

EPIC (GOR) impact on power generation, the life drilling or need for enhanced oil recovery, or dif- well interven- fcult reservoir fuid characteristics (high tion, dry or wet wax and wax appearance temperature, trees?

3.

H S or CO , heavy oil etc.) Is the feld 2 2

Where these factors apply, it is often short-lived? Do more practical to ask the question “given we need a re- an assumed production profle, oil price, usable solution?

4.

Opex and Net Present Value for the What are estimated reserves, what is the maximum the limiting 3

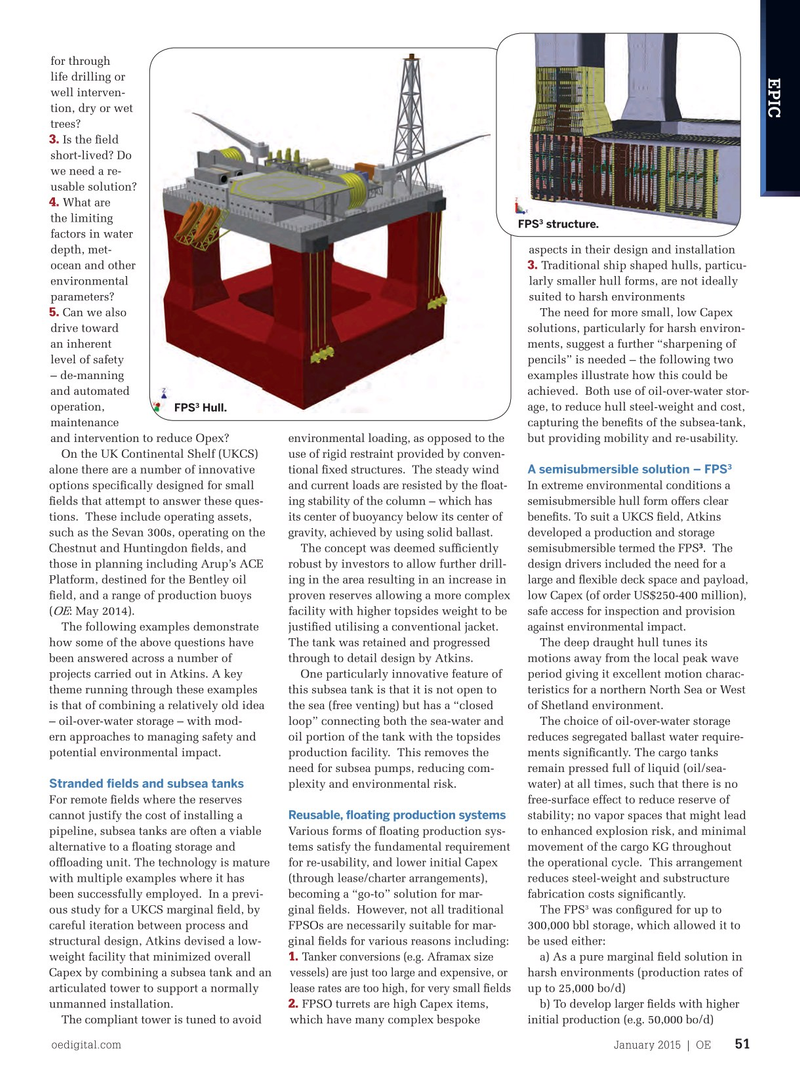

FPS structure.

Capex that still ensures an attractive factors in water return on investment?” depth, met- aspects in their design and installation 3. ocean and other Traditional ship shaped hulls, particu-

Characteristic solutions environmental larly smaller hull forms, are not ideally

In performing concept engineering and parameters? suited to harsh environments 5. selection, there are a number of guiding Can we also The need for more small, low Capex questions that we have found useful: drive toward solutions, particularly for harsh environ-

Is it marginal in production volumes, a an inherent ments, suggest a further “sharpening of 1. stranded feld, or both? level of safety pencils” is needed – the following two

What is the most practical/desir- – de-manning examples illustrate how this could be 2. able subsea design? From the number and automated achieved. Both use of oil-over-water stor- 3 of well completions, feld layout, need operation, age, to reduce hull steel-weight and cost, FPS Hull.

maintenance capturing the benefts of the subsea-tank, and intervention to reduce Opex? environmental loading, as opposed to the but providing mobility and re-usability.

On the UK Continental Shelf (UKCS) use of rigid restraint provided by conven- 3

A semisubmersible solution – FPS alone there are a number of innovative tional fxed structures. The steady wind options specifcally designed for small and current loads are resisted by the foat- In extreme environmental conditions a felds that attempt to answer these ques- ing stability of the column – which has semisubmersible hull form offers clear tions. These include operating assets, its center of buoyancy below its center of benefts. To suit a UKCS feld, Atkins such as the Sevan 300s, operating on the gravity, achieved by using solid ballast. developed a production and storage 3

Chestnut and Huntingdon felds, and The concept was deemed suffciently semisubmersible termed the FPS . The those in planning including Arup’s ACE robust by investors to allow further drill- design drivers included the need for a

Platform, destined for the Bentley oil ing in the area resulting in an increase in large and fexible deck space and payload, feld, and a range of production buoys proven reserves allowing a more complex low Capex (of order US$250-400 million),

OE ( : May 2014). facility with higher topsides weight to be safe access for inspection and provision

The following examples demonstrate justifed utilising a conventional jacket. against environmental impact. how some of the above questions have The tank was retained and progressed The deep draught hull tunes its been answered across a number of through to detail design by Atkins. motions away from the local peak wave projects carried out in Atkins. A key One particularly innovative feature of period giving it excellent motion charac- theme running through these examples this subsea tank is that it is not open to teristics for a northern North Sea or West is that of combining a relatively old idea the sea (free venting) but has a “closed of Shetland environment.

– oil-over-water storage – with mod- loop” connecting both the sea-water and The choice of oil-over-water storage ern approaches to managing safety and oil portion of the tank with the topsides reduces segregated ballast water require- potential environmental impact. production facility. This removes the ments signifcantly. The cargo tanks need for subsea pumps, reducing com- remain pressed full of liquid (oil/sea-

Stranded felds and subsea tanks plexity and environmental risk. water) at all times, such that there is no

For remote felds where the reserves free-surface effect to reduce reserve of

Reusable, foating production systems cannot justify the cost of installing a stability; no vapor spaces that might lead pipeline, subsea tanks are often a viable Various forms of foating production sys- to enhanced explosion risk, and minimal alternative to a foating storage and tems satisfy the fundamental requirement movement of the cargo KG throughout offoading unit. The technology is mature for re-usability, and lower initial Capex the operational cycle. This arrangement with multiple examples where it has (through lease/charter arrangements), reduces steel-weight and substructure been successfully employed. In a previ- becoming a “go-to” solution for mar- fabrication costs signifcantly.

3 ous study for a UKCS marginal feld, by ginal felds. However, not all traditional The FPS was confgured for up to careful iteration between process and FPSOs are necessarily suitable for mar- 300,000 bbl storage, which allowed it to structural design, Atkins devised a low- ginal felds for various reasons including: be used either: 1. Tanker conversions (e.g. Aframax size weight facility that minimized overall a) As a pure marginal feld solution in vessels) are just too large and expensive, or

Capex by combining a subsea tank and an harsh environments (production rates of lease rates are too high, for very small felds articulated tower to support a normally up to 25,000 bo/d) 2. unmanned installation. FPSO turrets are high Capex items, b) To develop larger felds with higher

The compliant tower is tuned to avoid which have many complex bespoke initial production (e.g. 50,000 bo/d) oedigital.com January 2015 | OE 51 050_OE0115_EPIC2_Adkins.indd 51 12/22/14 6:47 PM

48

48

50

50