Page 45: of Offshore Engineer Magazine (Feb/Mar 2015)

Read this page in Pdf, Flash or Html5 edition of Feb/Mar 2015 Offshore Engineer Magazine

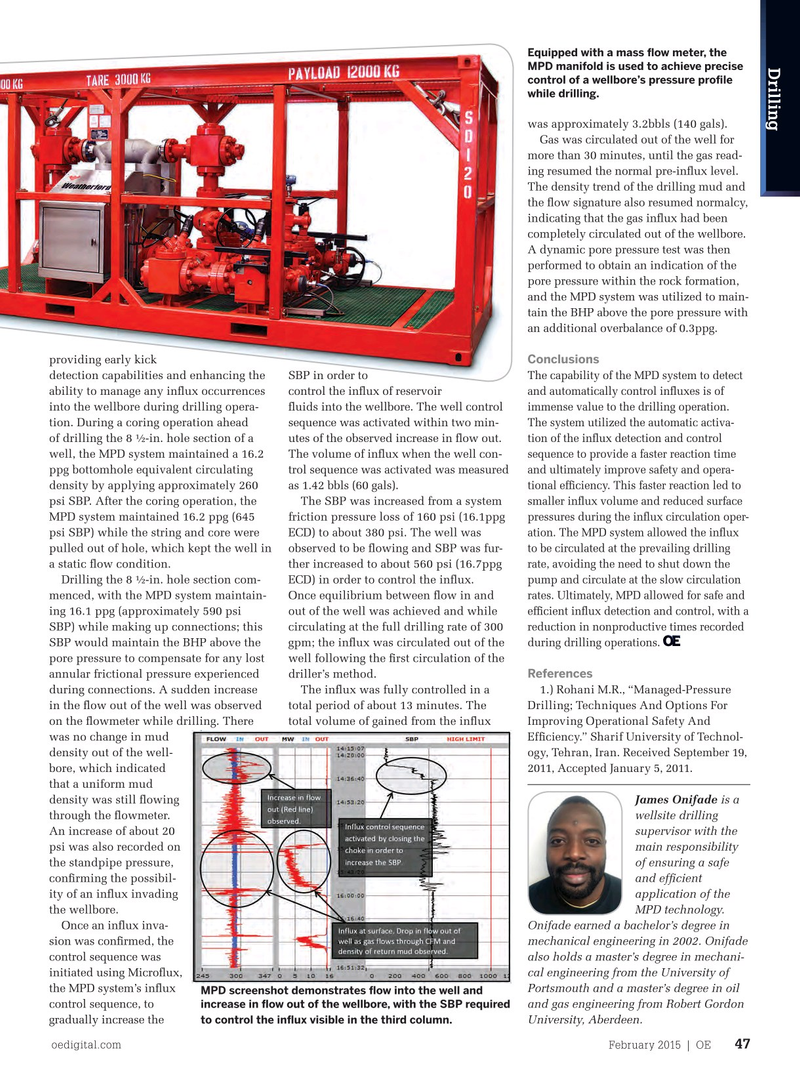

Equipped with a mass fow meter, the

Drilling

MPD manifold is used to achieve precise control of a wellbore’s pressure profle while drilling.

was approximately 3.2bbls (140 gals).

Gas was circulated out of the well for more than 30 minutes, until the gas read- ing resumed the normal pre-infux level.

The density trend of the drilling mud and the fow signature also resumed normalcy, indicating that the gas infux had been completely circulated out of the wellbore.

A dynamic pore pressure test was then performed to obtain an indication of the pore pressure within the rock formation, and the MPD system was utilized to main- tain the BHP above the pore pressure with an additional overbalance of 0.3ppg.

Conclusions providing early kick

The capability of the MPD system to detect detection capabilities and enhancing the SBP in order to and automatically control infuxes is of ability to manage any infux occurrences control the infux of reservoir immense value to the drilling operation. into the wellbore during drilling opera- fuids into the wellbore. The well control

The system utilized the automatic activa- tion. During a coring operation ahead sequence was activated within two min- tion of the infux detection and control of drilling the 8 ½-in. hole section of a utes of the observed increase in fow out. sequence to provide a faster reaction time well, the MPD system maintained a 16.2 The volume of infux when the well con- and ultimately improve safety and opera- ppg bottomhole equivalent circulating trol sequence was activated was measured tional effciency. This faster reaction led to density by applying approximately 260 as 1.42 bbls (60 gals).

smaller infux volume and reduced surface psi SBP. After the coring operation, the The SBP was increased from a system pressures during the infux circulation oper-

MPD system maintained 16.2 ppg (645 friction pressure loss of 160 psi (16.1ppg ation. The MPD system allowed the infux psi SBP) while the string and core were ECD) to about 380 psi. The well was to be circulated at the prevailing drilling pulled out of hole, which kept the well in observed to be fowing and SBP was fur- rate, avoiding the need to shut down the a static fow condition. ther increased to about 560 psi (16.7ppg pump and circulate at the slow circulation

Drilling the 8 ½-in. hole section com- ECD) in order to control the infux. required to circulate and condition the menced, with the MPD system maintain- Once equilibrium between fow in and rates. Ultimately, MPD allowed for safe and mud weight throughout the wellbore in ing 16.1 ppg (approximately 590 psi out of the well was achieved and while effcient infux detection and control, with a overbalanced drilling. SBP) while making up connections; this circulating at the full drilling rate of 300 reduction in nonproductive times recorded

MPD also provides considerable safety SBP would maintain the BHP above the gpm; the infux was circulated out of the during drilling operations. and environmental benefts. Return fow pore pressure to compensate for any lost well following the frst circulation of the

References is diverted away from the rig foor to a annular frictional pressure experienced driller’s method. Rohani M.R., “Managed-Pressure dedicated choke manifold by the use of during connections. A sudden increase The infux was fully controlled in a 1.)

Drilling; Techniques And Options For a rotating control device (RCD), thereby in the fow out of the well was observed total period of about 13 minutes. The

Improving Operational Safety And reducing accompanying hazards to rig on the fowmeter while drilling. There total volume of gained from the infux

Effciency.” Sharif University of Technol- foor personnel. was no change in mud

Fl ogy, Tehran, Iran. Received September 19, ow measurement is critical to the density out of the well-

MPD system, and is achieved through a bore, which indicated 2011, Accepted January 5, 2011.

mass fowmeter installed downstream of that a uniform mud the chokes on the MPD manifold. The density was still fowing James Onifade is a mass fow meter provides accurate fow through the fowmeter. wellsite drilling readings and enables early kick detec- An increase of about 20 supervisor with the tion. Due to the fact that infuxes can be psi was also recorded on main responsibility detected and controlled earlier and the the standpipe pressure, of ensuring a safe annular pressure profle manipulated as confrming the possibil- and effcient required, casing setting depths can be ity of an infux invading application of the extended. Industry studies suggest that the wellbore. MPD technology. the proper utilization of MPD may lead Once an infux inva- Onifade earned a bachelor’s degree in to the elimination or extension of casing sion was confrmed, the mechanical engineering in 2002. Onifade 1 setting points. control sequence was also holds a master’s degree in mechani- initiated using Microfux, cal engineering from the University of

Infux control ofshore Africa the MPD system’s infux Portsmouth and a master’s degree in oil

MPD screenshot demonstrates fow into the well and

An operator working off Africa employed control sequence, to and gas engineering from Robert Gordon increase in fow out of the wellbore, with the SBP required the MPD system for the frst time, gradually increase the University, Aberdeen. to control the infux visible in the third column.

oedigital.com February 2015 | OE 47 046_OE0215_D&C2_Weatherford.indd 47 1/20/15 6:27 PM

44

44

46

46