Page 44: of Offshore Engineer Magazine (Feb/Mar 2015)

Read this page in Pdf, Flash or Html5 edition of Feb/Mar 2015 Offshore Engineer Magazine

Drilling providing early kick detection capabilities and enhancing the ability to manage any infux occurrences into the wellbore during drilling opera- tion. During a coring operation ahead of drilling the 8 ½-in. hole section of a well, the MPD system maintained a 16.2 ppg bottomhole equivalent circulating density by applying approximately 260 psi SBP. After the coring operation, the

MPD system maintained 16.2 ppg (645 psi SBP) while the string and core were pulled out of hole, which kept the well in Infux a static fow condition.

Drilling the 8 ½-in. hole section com-

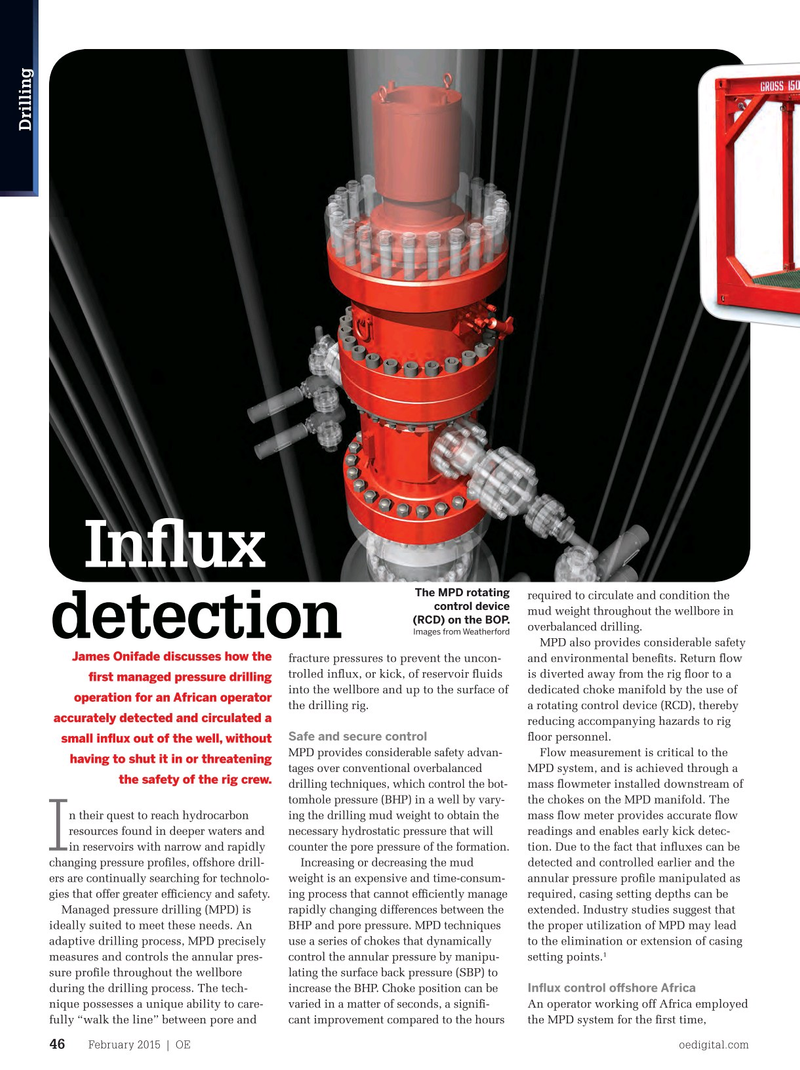

The MPD rotating required to circulate and condition the menced, with the MPD system maintain- control device mud weight throughout the wellbore in ing 16.1 ppg (approximately 590 psi (RCD) on the BOP. overbalanced drilling. SBP) while making up connections; this

Images from Weatherford detection

MPD also provides considerable safety SBP would maintain the BHP above the

James Onifade discusses how the and environmental benefts. Return fow fracture pressures to prevent the uncon- pore pressure to compensate for any lost is diverted away from the rig foor to a trolled infux, or kick, of reservoir fuids annular frictional pressure experienced frst managed pressure drilling dedicated choke manifold by the use of into the wellbore and up to the surface of during connections. A sudden increase operation for an African operator a rotating control device (RCD), thereby the drilling rig. in the fow out of the well was observed accurately detected and circulated a reducing accompanying hazards to rig on the fowmeter while drilling. There

Safe and secure control foor personnel. was no change in mud small infux out of the well, without ow measurement is critical to the density out of the well-

MPD provides considerable safety advan- Fl having to shut it in or threatening tages over conventional overbalanced

MPD system, and is achieved through a bore, which indicated the safety of the rig crew.

drilling techniques, which control the bot- mass fowmeter installed downstream of that a uniform mud tomhole pressure (BHP) in a well by vary- the chokes on the MPD manifold. The density was still fowing ing the drilling mud weight to obtain the mass fow meter provides accurate fow n their quest to reach hydrocarbon through the fowmeter. necessary hydrostatic pressure that will readings and enables early kick detec- resources found in deeper waters and An increase of about 20

I counter the pore pressure of the formation. tion. Due to the fact that infuxes can be in reservoirs with narrow and rapidly psi was also recorded on detected and controlled earlier and the Increasing or decreasing the mud changing pressure profles, offshore drill- the standpipe pressure, annular pressure profle manipulated as weight is an expensive and time-consum- ers are continually searching for technolo- confrming the possibil- required, casing setting depths can be ing process that cannot effciently manage gies that offer greater effciency and safety. ity of an infux invading extended. Industry studies suggest that rapidly changing differences between the Managed pressure drilling (MPD) is the wellbore. the proper utilization of MPD may lead BHP and pore pressure. MPD techniques ideally suited to meet these needs. An Once an infux inva- to the elimination or extension of casing use a series of chokes that dynamically adaptive drilling process, MPD precisely sion was confrmed, the 1 setting points. control the annular pressure by manipu- measures and controls the annular pres- control sequence was lating the surface back pressure (SBP) to sure profle throughout the wellbore initiated using Microfux,

Infux control ofshore Africa increase the BHP. Choke position can be during the drilling process. The tech- the MPD system’s infux

An operator working off Africa employed varied in a matter of seconds, a signif- nique possesses a unique ability to care- control sequence, to the MPD system for the frst time, cant improvement compared to the hours fully “walk the line” between pore and gradually increase the

February 2015 | OE oedigital.com 46 046_OE0215_D&C2_Weatherford.indd 46 1/20/15 6:27 PM

43

43

45

45