Page 19: of Offshore Engineer Magazine (Apr/May 2015)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2015 Offshore Engineer Magazine

Field of View

Fit for purpose from day one

With fshing activity possible, the Solutions (formally Kvaerner) electro

To provide a sound and structured larger pipelines are designed for fsh- hydraulic multiplexed control system development, the emphasis was on using ing gear pullover loads and the smaller expandable by two wells and one mani- proven, qualifed technology, simple ft- 4in lines and umbilicals are trenched. fold. These are controlled directly from for-purpose designs, with no single point Subsea structures in the shallower the shore terminal, 90km away, with a

West Delta Deep Marine- failure causing a complete shutdown of waters are designed to be the subsea system. overtrawlable, while in

The gas produced from the WDDM deeper waters, the struc- reservoirs is sweet, but pressures and tures are upright. Initially

Expansion beyond Limits temperatures are such that there is a con- considered for up to 200m tinual risk of hydrates from the produced water depth, this has been (PLEM) to the shore reception facilities, water. Continuous mono-ethylene glycol increased to 400m for phase built at Idku, near Alexandria. It was (MEG) injection, complete with corro- IX.

designed to allow for expansion from the sion inhibitor, is provided via dedicated Subsea equipment initial 700 MMscf/d to 2000 MMscf/d. pipelines routed to each feld area. In includes horizontal trees,

Subsequent phases were to be dedicated addition to the produced water, the with the fowloop connector to the adjacent LNG plant and to main- Sapphire feld also produces a signifcant hub mounted directly on tain a production plateau throughout a amount of condensate that is required the tree body, and remotely feld life of 25 years. to be extracted prior to the gas entering installed tie-in jumper

Intecsea has worked in partnership the domestic market or the adjacent LNG spools connecting the trees with the joint venture company opera- plant. and manifolds to the infeld tor Burullus (EGPC 50%, BG Group Pipelines on WDDM are carbon steel fow lines. 25%, Petronas 25%) and undertaken the ranging from 10in for well fowlines,

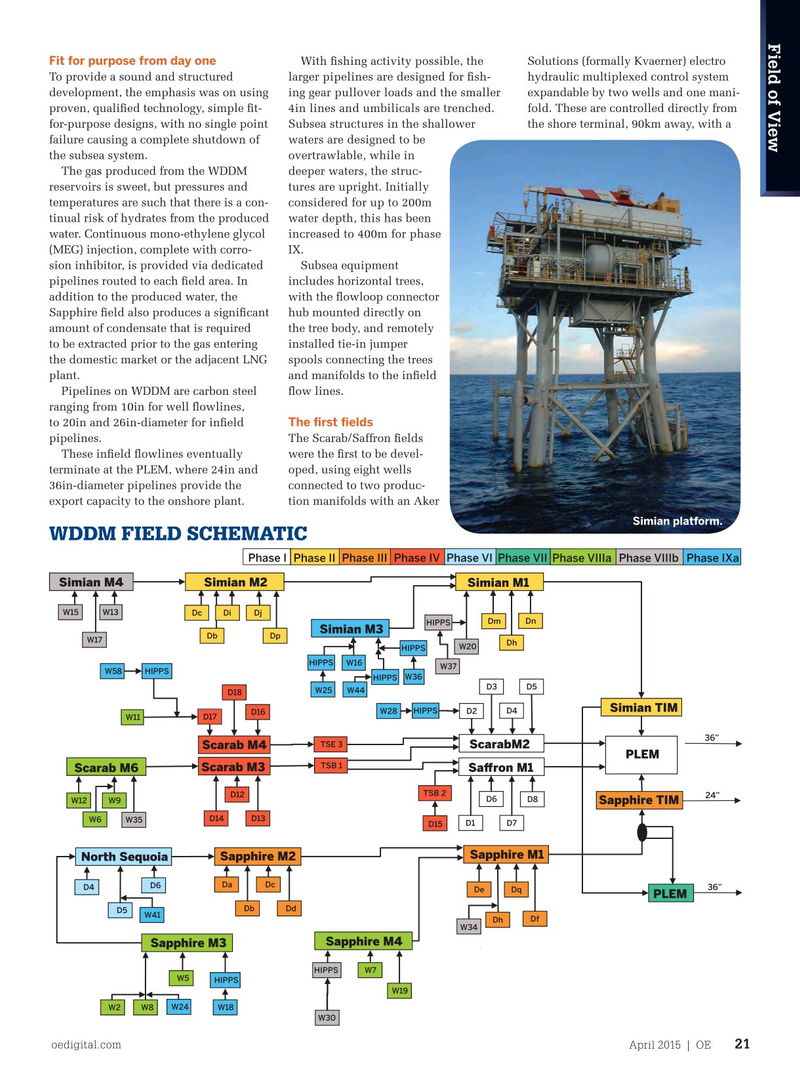

The frst felds conceptual design, front-end engineering to 20in and 26in-diameter for infeld design and the technical assurance for all pipelines. The Scarab/Saffron felds phases of WDDM development to date These infeld fowlines eventually were the frst to be devel- and is currently supplying a technical terminate at the PLEM, where 24in and oped, using eight wells assurance support team to Burullus on 36in-diameter pipelines provide the connected to two produc- the latest Phase IXa development. export capacity to the onshore plant. tion manifolds with an Aker

Simian platform.

WDDM

18

18

20

20