Page 48: of Offshore Engineer Magazine (Apr/May 2015)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2015 Offshore Engineer Magazine

might be plagued by several planned (and unplanned) interventions, says Brian

Skeels, emerging technology director at

FMC Technologies and an adjunct profes-

Intervening sor of subsea engineering at the University

EyebrowProduction of Houston.

While Pompano is currently the only feld using a TFL system in the Gulf of

Mexico, it’s not the only one in the world.

on Pompano “What started with Exxon’s SPS project at Garden Banks 70/71 back in the 1970’s

Unique felds deserve equally unique intervention solutions later moved to Shell/Esso’s Central when production begins to wane, this was the challenge

Cormorant project in the UK’s North Sea

Stone Energy had to meet when it contracted Cross Group sector in the 1980s, and Statoil’s (Saga

Petroleum) Snorre project offshore Norway to develop new methodology and technology for its Pompano in 1992. TFL was also experimented with subsea production template. Audrey Leon reports.

on other North Sea pilot projects for Mobil and Conoco in the same era,” Skeels says.

hen Lafayette, Louisiana- Skeels, who serves on an API based Stone Energy pur- Subcommittee 17 executive committee,

W chased the Pompano feld says that TFL continues to have its merits. from BP in late 2011, the feld’s subsea “But, its cachet may have come and intervention kit was in need of serious gone,” he says, when compared to some of refurbishment while several subsea wells today’s lower cost intervention solutions on Pompano Phase II, a 10-well subsea like monohull riserless intervention. template remained shut-in. The way the TFL system works is that

In 2012, Stone Energy had 16 platform tools have to be pumped through a 4.5mi wells producing, and only three of 10 fowline from the Pompano platform template wells producing. An interven- and into a well in order to perform work tion would be necessary, but the subsea that is typically done with slickline on system, the only one of its kind in the US conventional dry tree wells. This requires

Gulf of Mexico, had issues such as stuck the TFL tools to be extremely fexible, tooling that made through-fowline (TFL) almost like snakes, says Jason Leath, intervention unworkable, said Craig Director of Projects at Cross Group.

Castille, director of Deepwater Drilling and Completion at Stone Energy.

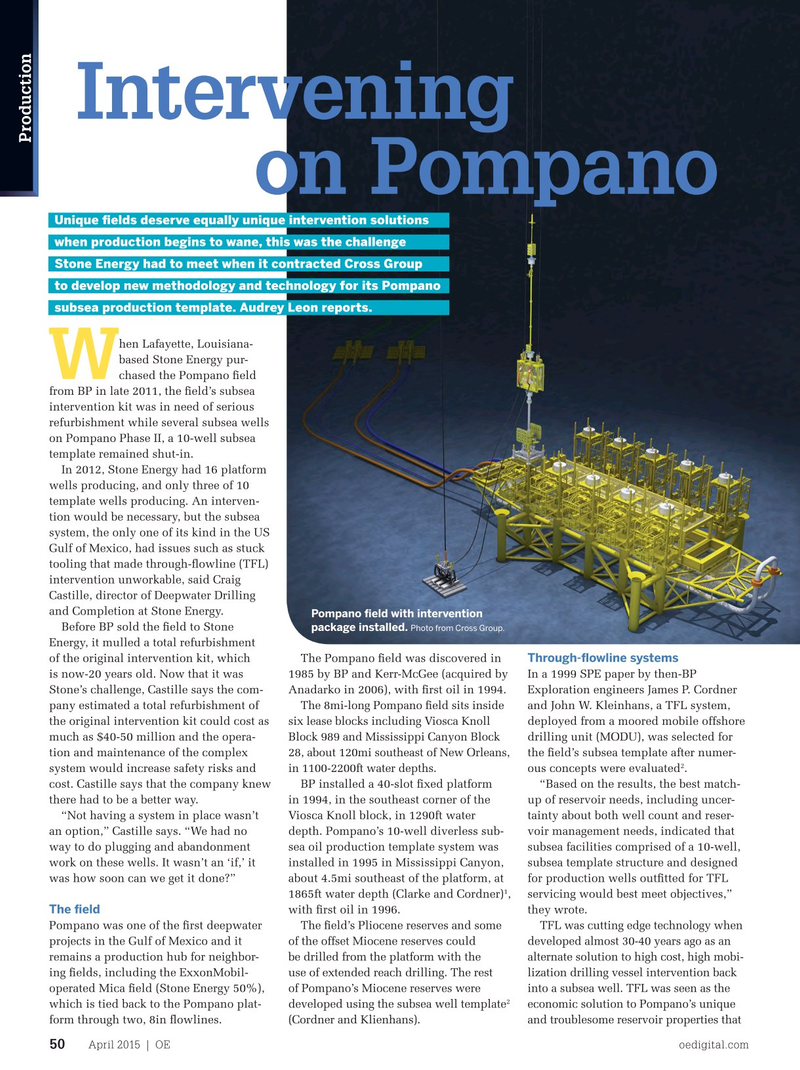

Pompano feld with intervention

Before BP sold the feld to Stone package installed. Photo from Cross Group.

Energy, it mulled a total refurbishment

Through-fowline systems of the original intervention kit, which The Pompano feld was discovered in is now-20 years old. Now that it was 1985 by BP and Kerr-McGee (acquired by In a 1999 SPE paper by then-BP

Stone’s challenge, Castille says the com- Anadarko in 2006), with frst oil in 1994. Exploration engineers James P. Cordner

The 8mi-long Pompano feld sits inside pany estimated a total refurbishment of and John W. Kleinhans, a TFL system, six lease blocks including Viosca Knoll the original intervention kit could cost as deployed from a moored mobile offshore

Block 989 and Mississippi Canyon Block much as $40-50 million and the opera- drilling unit (MODU), was selected for 28, about 120mi southeast of New Orleans, tion and maintenance of the complex the feld’s subsea template after numer- 2 in 1100-2200ft water depths. system would increase safety risks and ous concepts were evaluated . cost. Castille says that the company knew BP installed a 40-slot fxed platform “Based on the results, the best match- there had to be a better way. in 1994, in the southeast corner of the up of reservoir needs, including uncer- “Not having a system in place wasn’t Viosca Knoll block, in 1290ft water tainty about both well count and reser- an option,” Castille says. “We had no depth. Pompano’s 10-well diverless sub- voir management needs, indicated that way to do plugging and abandonment sea oil production template system was subsea facilities comprised of a 10-well, work on these wells. It wasn’t an ‘if,’ it installed in 1995 in Mississippi Canyon, subsea template structure and designed was how soon can we get it done?” about 4.5mi southeast of the platform, at for production wells outftted for TFL 1 1865ft water depth (Clarke and Cordner) , servicing would best meet objectives,”

The feld with frst oil in 1996. they wrote.

Pompano was one of the frst deepwater The feld’s Pliocene reserves and some

TFL was cutting edge technology when developed almost 30-40 years ago as an projects in the Gulf of Mexico and it of the offset Miocene reserves could alternate solution to high cost, high mobi- remains a production hub for neighbor- be drilled from the platform with the lization drilling vessel intervention back ing felds, including the ExxonMobil- use of extended reach drilling. The rest operated Mica feld (Stone Energy 50%), of Pompano’s Miocene reserves were into a subsea well. TFL was seen as the 2 economic solution to Pompano’s unique which is tied back to the Pompano plat- developed using the subsea well template and troublesome reservoir properties that form through two, 8in fowlines. (Cordner and Klienhans).

April 2015 | OE oedigital.com 50 050_OE0415_ProdOps_Pompano.indd 50 3/23/15 5:59 PM

47

47

49

49