Page 68: of Offshore Engineer Magazine (May/Jun 2015)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2015 Offshore Engineer Magazine

would be covered and the load could never come back too quickly on the load cell position. The 64, 536-tonne capac- ity, cylinders (one each per load cell) are

EPIC sited next to the load cells. Due to the limited space, a lifting yoke was created by EIVA SAFEX AS to put the cylinders in place. They also produced a sea- fastening system to secure the cylinders underneath the load. For each column, one complete control set (powerpack, control panel and hoses) is kept in the column storage cabins. Each column has its own hydraulic system and a 50-kilo pump unit, so neither have to be moved between columns.

The result is that the load cell calibration work has gone from 32 lifts to eight lifts

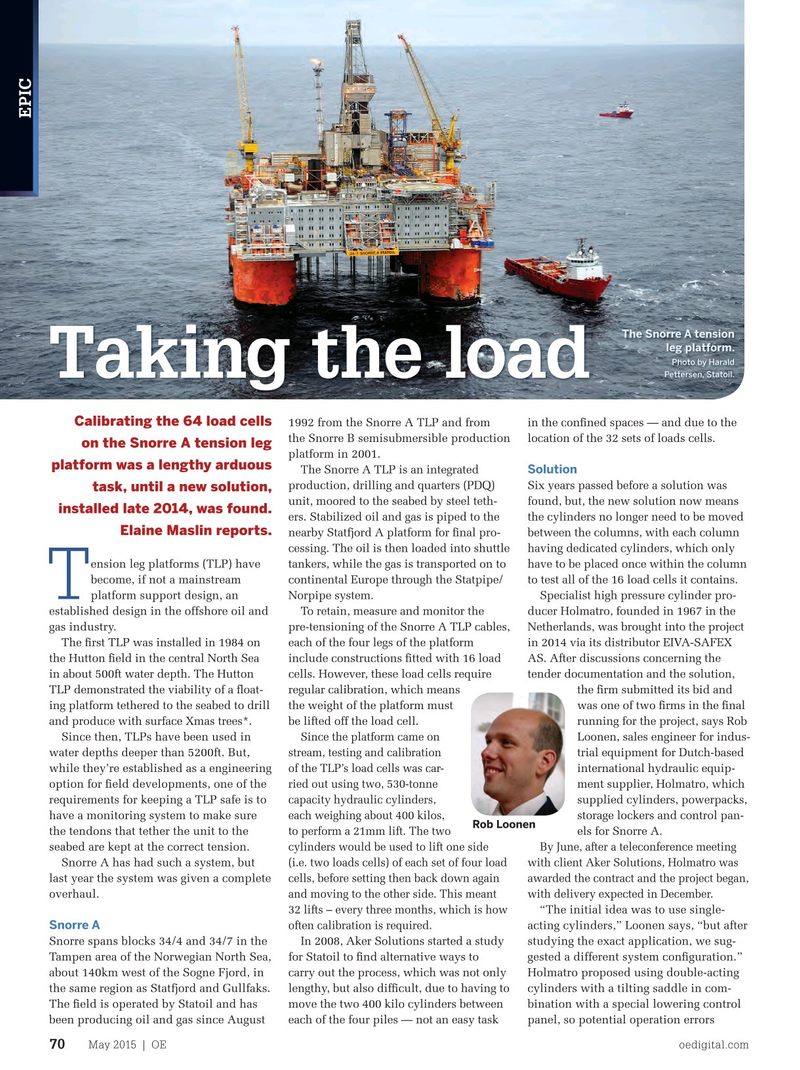

The Snorre A tension with no more equipment handling between leg platform. the platform’s columns. For Holmatro, it

Photo by Harald

Pettersen, Statoil.

Taking the load was an ideal job. While the company has about 170 standard cylinders available for the offshore sector and other industries, it

Calibrating the 64 load cells 1992 from the Snorre A TLP and from in the con? ned spaces — and due to the also specializes in bespoke solutions. “The nice part of this project is that it’s the Snorre B semisubmersible production location of the 32 sets of loads cells.

on the Snorre A tension leg an industrial solution,” Loonen says. “We platform in 2001. platform was a lengthy arduous

Solution always try to help a client get the right solu-

The Snorre A TLP is an integrated tions. In collaboration with our research production, drilling and quarters (PDQ) Six years passed before a solution was task, until a new solution, and development, production and service unit, moored to the seabed by steel teth- found, but, the new solution now means installed late 2014, was found. departments, we place ourselves in our ers. Stabilized oil and gas is piped to the the cylinders no longer need to be moved

Elaine Maslin reports.

nearby Statfjord A platform for ? nal pro- between the columns, with each column cessing. The oil is then loaded into shuttle having dedicated cylinders, which only ension leg platforms (TLP) have tankers, while the gas is transported on to have to be placed once within the column become, if not a mainstream continental Europe through the Statpipe/ to test all of the 16 load cells it contains.

T platform support design, an Norpipe system. Specialist high pressure cylinder pro- established design in the offshore oil and To retain, measure and monitor the ducer Holmatro, founded in 1967 in the gas industry. pre-tensioning of the Snorre A TLP cables, Netherlands, was brought into the project

The ? rst TLP was installed in 1984 on each of the four legs of the platform in 2014 via its distributor EIVA-SAFEX the Hutton ? eld in the central North Sea include constructions ? tted with 16 load AS. After discussions concerning the in about 500ft water depth. The Hutton cells.

67

67

69

69