Page 80: of Offshore Engineer Magazine (May/Jun 2015)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2015 Offshore Engineer Magazine

Subsea

Building blocks for an electric subsea future could be capable of managing most in September 2014, and its El-drive

Electronic subsea control deepwater subsea feld scenarios. actuator system.

modules are being designed to

Vectus comes with an electronics

But, these are not super-heavyweight, go deeper – and be smaller and module, auxiliary and power sup- giant pieces of hardware. Rather, they ply modules, while the electronic are modular, small – modest even – and lighter. John Bradbury actuator is also offered in a small, confgurable.

takes a look.

Einar Winther Larssen, a research modular package. Both are designed for and design manager within Aker deepwater.

Larssen foresees deployment of these ew generation subsea control

Solutions’ corporate technology orga- systems being rolled out to new units in a variety of subsea scenar- nization, describes these new units as

N the offshore industry could ios: in production and workover systems, “Next generation subsea electronics and actuation platforms,” which will one day become the key building in subsea pumping and compression have wide-ranging applications. “I blocks for both new and brownfeld applications, and within the “subsea think these types of systems will be factory” concept Aker Solutions has been developments.

That is the proud assertion of a senior promoting across the industry.

suitable for all [subsea] systems in the engineering research manager who sug- The hardware can be used without future,” Larssen says.

gests his company’s new subsea elec- Aker Solutions’s offering is based on performing too many mechanical changes tronic control modules and actuators its Vectus 6.0 subsea control unit released Larssen says, using confgurable software

Claire Zhao and Dharmik Vadel, of Clarus Subsea

Integrity, discuss condition monitoring as a proactive

Enhanced IM approach to minimizing downtime.

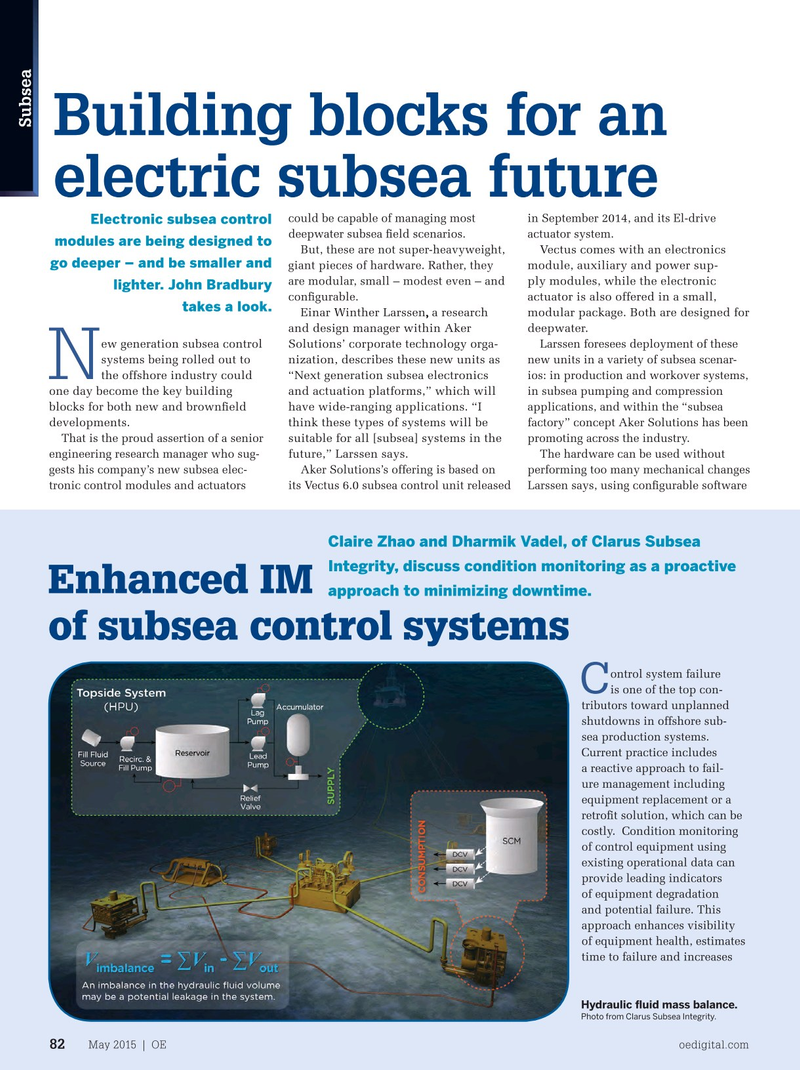

of subsea control systems ontrol system failure

C is one of the top con- tributors toward unplanned shutdowns in offshore sub- sea production systems.

Current practice includes a reactive approach to fail- ure management including equipment replacement or a retroft solution, which can be costly. Condition monitoring of control equipment using existing operational data can provide leading indicators of equipment degradation and potential failure. This approach enhances visibility of equipment health, estimates time to failure and increases

Hydraulic fuid mass balance.

Photo from Clarus Subsea Integrity.

May 2015 | OE oedigital.com 82 082_OE0515_Subsea1+2.indd 82 4/20/15 8:24 PM

79

79

81

81