Page 90: of Offshore Engineer Magazine (May/Jun 2015)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2015 Offshore Engineer Magazine

performs with higher tem- perature injection water and considering the effects of chemicals used for enhanced oil recovery (EOR).

Pipelines

Using polymer liners in hydrocarbon pipelines can deliver signi? cant techni- cal advantages. Not only are they fully corrosion resistant, polymer liners are also rela- tively smooth compared to steel and metallurgic alloys.

The low roughness of poly- mers minimizes the pressure drop across the pipeline, which is maintained along the lifetime of the pipeline, unlike steel/CRA roughness which degrades due to ero- installation of polymer sion and corrosion. liner into steel string.

The elastic nature of polymers is also more tolerant to both

Polyethylene materials may be consid- to the permeated pressure gas build-up ? uid and particle erosion. These ? uids ered for hydrocarbon applications but as in the annular gap between the polymer often contain debris and deposits, service environments change as tempera- liner and the inner wall of the carbon which can accumulate on the inner wall ture increases, above 50°C the properties steel pipeline. Additionally, the issue of a pipeline, causing ? ow restrictions of ‘engineered polymers’ such as poly- of potential liner swelling when in and occasionally, blockages. It is envis- amides and polyvinylidene di? uoride contact with hydrocarbons needs to be aged that the adhesion between ? uid (PVDF) may be preferential. considered. deposits, for example wax and hydrates,

The technology’s internal pipeline Work to address this is currently being and polymer material is lower than that corrosion protection has great potential carried out by Swagelining (a UK-based of steel, which decreases this block- for usage in hydrocarbon pipelines using specialist in the design and installation age risk and reduces pigging frequency engineered polymers. It is recognized of polymer linings), which has recently requirements. that the use of polymer liners in subsea embarked upon a joint industry project (JIP) with The Welding Institute (TWI) production pipelines has yet to be fully An additional advantage for regular

YOUR WORLD- and Saudi Aramco. This JIP will exam- developed and that there are challenges hydrocarbon service is that polymers ine the extent of corrosion incurred in a in this arena, which must be resolved have good heat insulation properties and

CLASS PARTNER variety of polymer lined pipelines when before polymer lining can be considered add signi? cantly to the thermal perfor-

FOR WELL subjected to a hot sour hydrocarbon in every service application, but these are mance of a pipeline system. For example, environment. now being seriously considered by opera- a layer of polymer between 10-15mm

INTERVENTION.

Swagelining is also currently carrying tors worldwide. will have a signi? cant effect on the out technical quali? cation programs with Theoretically, in hydrocarbon service, pipeline overall heat transfer coef? cient,

JDR is a global leader for reliable operators, identifying how polyethylene the threat of liner collapse exists, due greatly reducing the outer insulation

IWOC systems. From design to 25 delivery, we engineer our products £2500 to ensure safe and reliable

CS (with corrosion allowance) 625 lined deployment. To build on that, we 20 £2000 625 clad offer installation and maintenance

PVDF lined support throughout project

Be sure to visit us at Stand 1523 at OTC

PE 100 lined planning, mobilisation, installation, 4-7 May in Houston to learn more about JDR.

15 £1500 repair, planned maintenance and spares. JDR is totally committed 10 to the lifecycle of our products. £1000

We’re there every step of the way.

5 £500 -including insulation (in millions)

Procurement & fabrication costs (£M) @ConnectwithJDR • UNITED KINGDOM • SINGAPORE £0 0 0123456789 10 625 PE 100 CS (with PVDF 625 • UNITED STATES • GERMANY /jdr-cable-systems lined corrosion lined lined clad

Procurement and fabrication cost (£/m)-including insulation

Pipeline length (km) • WEST AFRICA • BRASIL allowance) /ConnectwithJDR • THAILAND

WWW.JDRGLOBAL.COM

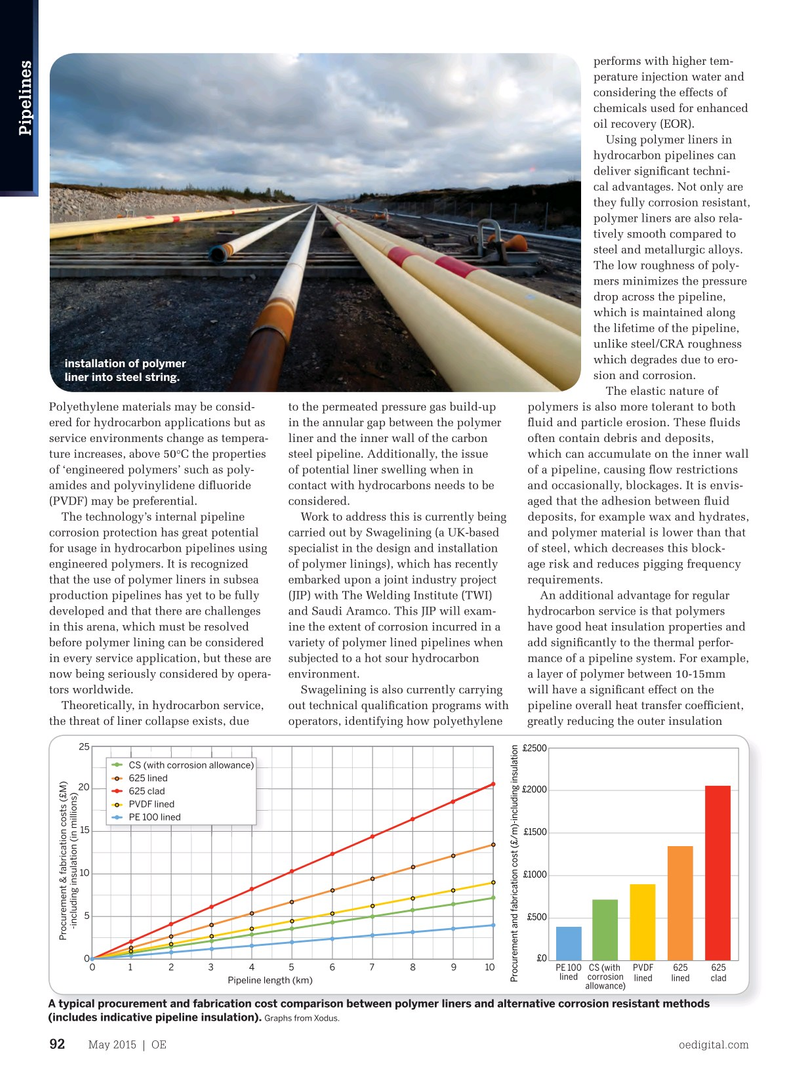

A typical procurement and fabrication cost comparison between polymer liners and alternative corrosion resistant methods (includes indicative pipeline insulation).

Graphs from Xodus.

May 2015 | OE oedigital.com 92 090_OE0515_Pipelines2_Polymer_JIP.indd 92 4/20/15 9:05 PM

89

89

91

91