Page 32: of Offshore Engineer Magazine (Sep/Oct 2015)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2015 Offshore Engineer Magazine

before a discovery was even made. Part of this was due to the

FPSO fact that the 20 or so deepwater leases acquired for production by

LLOG in 2010 were set to expire in early 2014 – requiring expe- dition of the entire construction process so that the FPS could be brought online and wells could be drilled within 36 months.

In order to achieve this milestone and keep pace with the highly aggressive production schedule, topsides engineering con- tractor Audubon Engineering Solutions had to begin front-end engineering design (FEED) efforts before reservoir characteristics were de? ned.

Assuming a reservoir composition similar to a nearby analo-

A stabilizing gous ? eld (GOR of ~2000 scf/bbl and 28-32°API), the initial design included routing liquids from compressor scrubbers to production separators with lower operating pressures – a method commonly used on offshore facilities to reduce liquid recycle and minimize compression requirements.

During this initial design process, however, a well sample design phase behavior (pressure, volume, temperature or PVT) analysis conducted by a third-party laboratory revealed that the reser- voir contained a stock GOR of approximately 2300 scf/bbl and oping with unexpected engineering challenges during a crude oil gravity of 38°API – a substantial deviation from the

Audubon Companies’ Denis Taylor the design and development of infrastructure is some- previously assumed composition. The analysis also indicated

C thing that is inherent in the deepwater offshore oil and that reservoir ? uid was rich in condensates, including propane and LLOG Exploration’s Craig gas industry. (C3), butane (C4), and pentane (C5), resulting in a much larger

Case in point: LLOG Exploration’s Delta House ? oating pro- liquid recycle and higher compression requirements in order

Mullett discuss changing design duction system (FPS) in the Gulf of Mexico (GoM). to meet oil pipeline Reid vapor pressure (RVP) speci? cations.

Delta House, in Mississippi Canyon Block 254, was built under Although Audubon Engineering Solutions and LLOG were considerations for condensate a rather unique set of circumstances. Unlike the conventional suspicious whether this data was entirely accurate, given the approach taken by most offshore operators, which involves delin- unusual numbers, they proceeded under that assumption that if stabilization on the Delta House FPS in eating wells and studying reservoir composition before detailed it were even remotely indicative of the reservoir’s composition, design and construction begins, work on Delta House started a conventional liquids handling philosophy would be impracti- the Gulf of Mexico.

cal and other options would need to be explored.

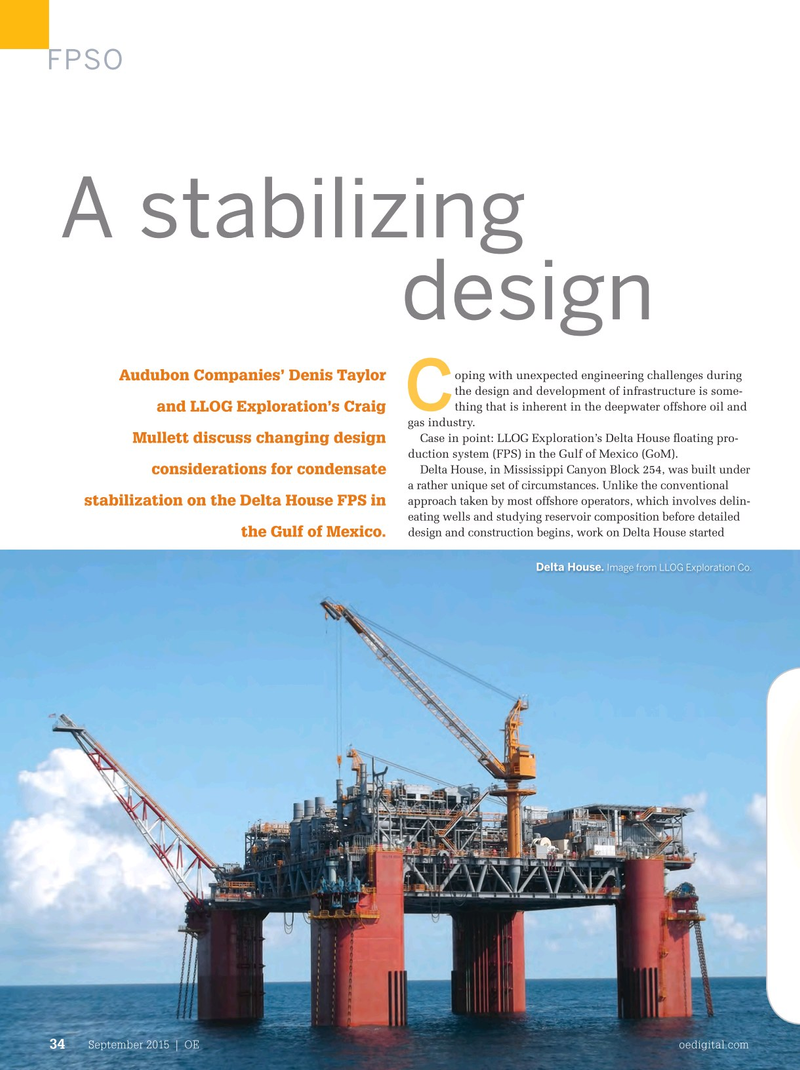

Delta House. Image from LLOG Exploration Co.

Liquid handling options

When considering a new liquid handling design approach, two options were examined. The ? rst option was to retain much of the equipment used in the original design and add a conden- sate processing train in order to dehydrate the condensate from

To compression

Coalescing Overhead

To compression ?lters condenser

Overhead separator

From

To sales

FGC scrubbers

NGL

Condensate

Freewater

Charge pumps &

Stabilizer knockout pipeline pumps

Reboiler

To LP SEP

Bottom

To LP SEP

Cooler

Stabilized condensate

September 2015 | OE oedigital.com 34 034_OE0915_Feat3_Audubon.indd 34 8/19/15 8:01 PM

31

31

33

33