Page 66: of Offshore Engineer Magazine (Sep/Oct 2015)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2015 Offshore Engineer Magazine

permanently in a well that is being P&A’d, which could be deployed on says Neil Gardner, global sales and busi- smaller platforms, such as in ness development director for Ziebel. the southern North Sea, where a CT-like Z-System unit might

Z-System not ? t.

Eyebrow Production

Ziebel’s ? rst DFO sensing system was The result was the devel- the Z-System, which deploys ? ber optic opment of the Z-Line, a cables via a 15mm diameter semi-stiff smaller 4.8mm-diameter carbon composite rod, using a unit very carbon composite line, with

Carbon sense similar to a light coiled tubing (CT) unit. a 6600lb/3000kg breaking carbon technology conveyance systems

Once “parked” stationary in the well, the strength, containing up to six

Flow visualization to make distributed temperature sensing system acquires DTS and DAS along the ? ber optic cables encased in in horizontal wells is being (DTS) and distributed acoustic sensing full length of the rod. The concept for the a central steel tube. It comes improved thanks to carbon (DAS) measurements simultaneously technology was initially developed in the mounted on a 1m-diameter across the entire interval of interest in early 2000s, with a patent eventually being drum, which can run on a composite rods. an easier and faster manner, with the granted in 2006. standard wireline type set-up,

Elaine Maslin takes a look. high strength of carbon ? ber reducing the “The idea was patented to use a carbon and includes point pressure risk of not being able to retrieve the ? ber composite rod with ? ber optics inside to and temperature sensors on unning wireline production log- optics from the well. enter a well in order to measure param- the bottom hole assembly. “It ging (PL) tools into horizontal The Norwegian ? rm’s new 4.8mm- eters like temperature, pressure and oth- is smaller and more modular,

R wells has never been that easy. diameter Z-Line system has seen its ? rst ers,” Gardner says.

which opens up many more

Since then, a lot of work was done

The tool strings with the PL sensors have commercial operational use on Statoil’s wells to be investigated using re? ning the product, particularly experi- to either be run on the end of coiled Huldra platform in the Norwegian North ? ber optics,” Gardner says. menting with different sizes and con? gura- tubing or pulled along the horizontal sec- Sea earlier this year as part of a project to “Because it is 4.8mm, it is tions of the rod, as well as the chemistry tions with a well tractor, both methods assess well conditions ahead of a plugging much more ? exible and can of the composite rod material, with the having operational drawbacks (time and and abandonment (P&A) campaign next be deployed like a mechanical

University of Aberdeen providing math- cost) as well as frequent dif? culties in year. It was the ? rst time Statoil has com- wireline or slick-line.” ematical modeling for different composite acquiring good quality, valid data sets. missioned a distributed ? ber optic (DFO) The system does preclude use behavior, so that it would be able to per-

Even when a wireline tool acquires well intervention and it was also Ziebel’s on horizontal wells because you form the tasks required of it and withstand good data, the sensor is only able to make ? rst operation for Statoil. cannot push it in – it requires downhole conditions. a measurement at one depth point at any The next step could be leaving a sinker bars and gravity to move given time. Ziebel employs its composite “The idea was to be able to push the composite carbon rod or line downhole it down into the well. But, it semi-stiff rod out into horizontal well will go into relatively high-devi- sections,” Gardner says. “The horizontal ation wells, Gardner says – up

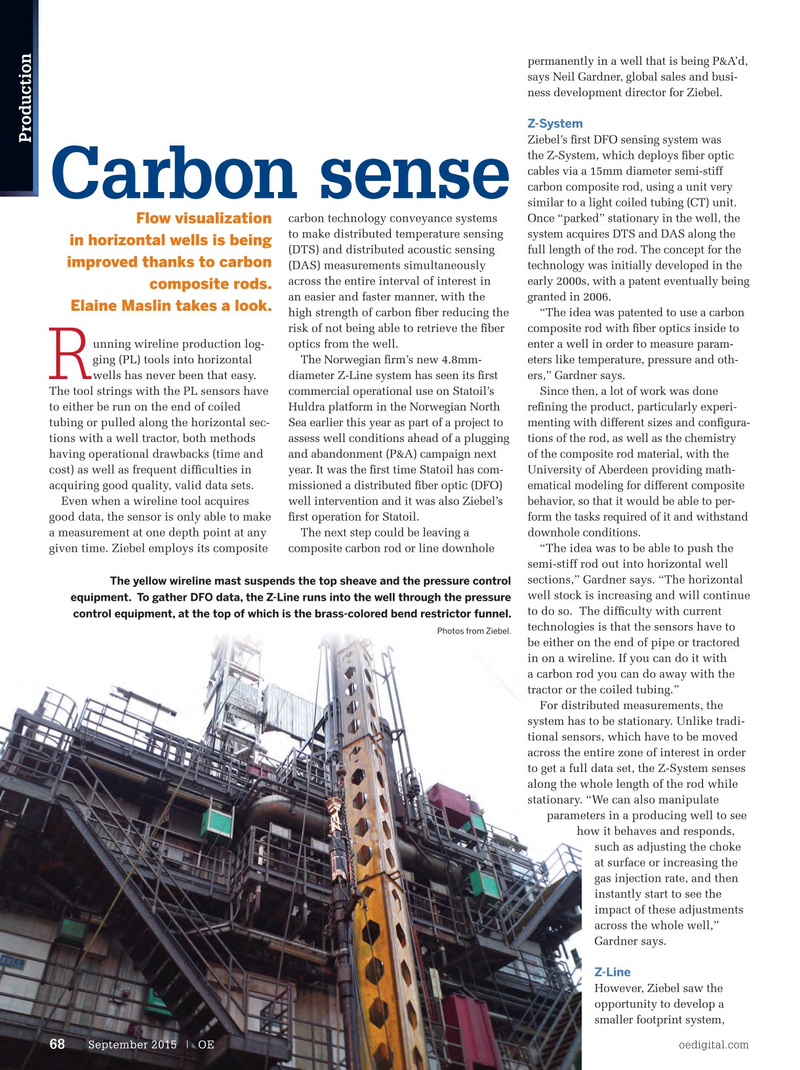

The yellow wireline mast suspends the top sheave and the pressure control well stock is increasing and will continue to 75-80° deviation, depending equipment. To gather DFO data, the Z-Line runs into the well through the pressure to do so. The dif? culty with current on the well geometry, according control equipment, at the top of which is the brass-colored bend restrictor funnel. technologies is that the sensors have to to the company’s calculations.

Photos from Ziebel.

be either on the end of pipe or tractored Z-Lines could be built as long in on a wireline. If you can do it with as required by well depths, but a carbon rod you can do away with the the main application of interest tractor or the coiled tubing.” (well integrity surveys) are in

For distributed measurements, the the shallower vertical section of system has to be stationary. Unlike tradi- most wells. The length is only limited by tional sensors, which have to be moved the space available on the drum and the across the entire zone of interest in order ability to properly control the manufac- to get a full data set, the Z-System senses turing process, Gardner says. The ? rm along the whole length of the rod while has built a 4000m-long version and it is stationary. “We can also manipulate aiming to build the next systems to at parameters in a producing well to see least 6000m length. The 3-4-tonne drum how it behaves and responds, of Z-Line is shipped offshore inside such as adjusting the choke an add-on-drum skid, with two sheave at surface or increasing the wheels, a Ziebel sensing cabin, and the gas injection rate, and then dynamic seal pressure control section.

Working from the Huldra platform, instantly start to see the

Ziebel ran the Z-Line in two wellbores impact of these adjustments to measure temperature and acoustic across the whole well,” pro? les. Work was carried out by Ziebel

Gardner says.

over two, three-day periods in April and

Z-Line

May 2015. Each operation was com-

However, Ziebel saw the pleted as planned, providing data that opportunity to develop a displays the conditions of each well in smaller footprint system, its entirety, during each intervention. It

September 2015 | OE oedigital.com 68 068_OE0915_ProdOps2_Ziebel.indd 68 8/20/15 10:44 AM

65

65

67

67