Page 25: of Offshore Engineer Magazine (Aug/Sep 2016)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2016 Offshore Engineer Magazine

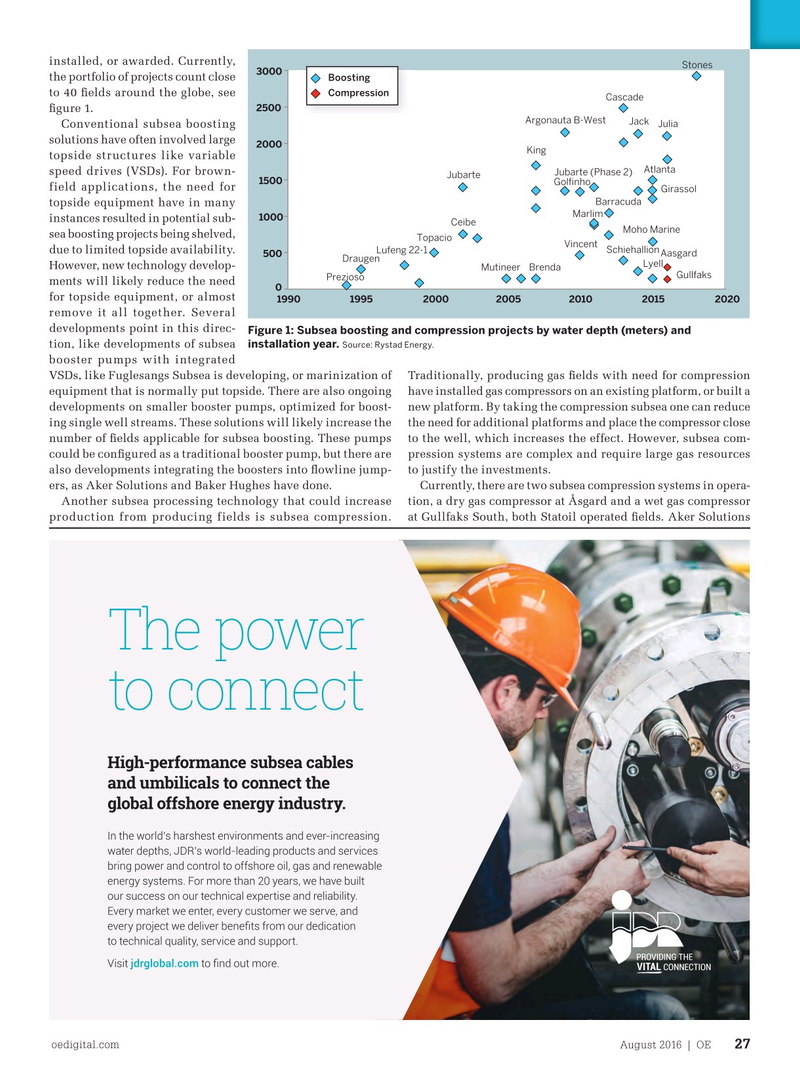

installed, or awarded. Currently,

Stones 3000 the portfolio of projects count close

Boosting

Compression to 40 ? elds around the globe, see

Cascade 2500 ? gure 1.

Argonauta B-West

Jack Julia

Conventional subsea boosting solutions have often involved large 2000

King topside structures like variable

Atlanta speed drives (VSDs). For brown-

Jubarte (Phase 2)

Jubarte 1500

Gol?nho field applications, the need for

Girassol

Barracuda topside equipment have in many

Marlim 1000 instances resulted in potential sub-

Ceibe

Moho Marine sea boosting projects being shelved,

Topacio

Vincent due to limited topside availability. 500 SchiehallionAasgard

Draugen Lufeng 22-1

Lyell

However, new technology develop-

MutineerBrenda

Gullfaks

Prezioso ments will likely reduce the need 0 for topside equipment, or almost 1990 1995 20002005 2010 2015 2020 remove it all together. Several developments point in this direc-

Figure 1: Subsea boosting and compression projects by water depth (meters) and tion, like developments of subsea installation year. Source: Rystad Energy.

booster pumps with integrated

VSDs, like Fuglesangs Subsea is developing, or marinization of Traditionally, producing gas ? elds with need for compression equipment that is normally put topside. There are also ongoing have installed gas compressors on an existing platform, or built a developments on smaller booster pumps, optimized for boost- new platform. By taking the compression subsea one can reduce ing single well streams. These solutions will likely increase the the need for additional platforms and place the compressor close number of ? elds applicable for subsea boosting. These pumps to the well, which increases the effect. However, subsea com- could be con? gured as a traditional booster pump, but there are pression systems are complex and require large gas resources also developments integrating the boosters into ? owline jump- to justify the investments. ers, as Aker Solutions and Baker Hughes have done. Currently, there are two subsea compression systems in opera-

Another subsea processing technology that could increase tion, a dry gas compressor at Åsgard and a wet gas compressor production from producing fields is subsea compression. at Gullfaks South, both Statoil operated ? elds. Aker Solutions

The oil price crash brings subsea processing opportunities, says Rystad

24

24

26

26