Page 42: of Offshore Engineer Magazine (Aug/Sep 2016)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2016 Offshore Engineer Magazine

Raising

SUBSEA resin’s pro? le formation wall. This interface

Endeavor Management’s can follow variations in the

Keith Caul? eld and Mike Cowan mating surface. There can be a chemical bond component to examine the results of a recent formation and casing, but the

JIP that showed resin may be a overall sealing bond is mainly a mechanical bond de? ned by potential alternative to cement friction and a solid-to-solid in P&A operations.

interface.

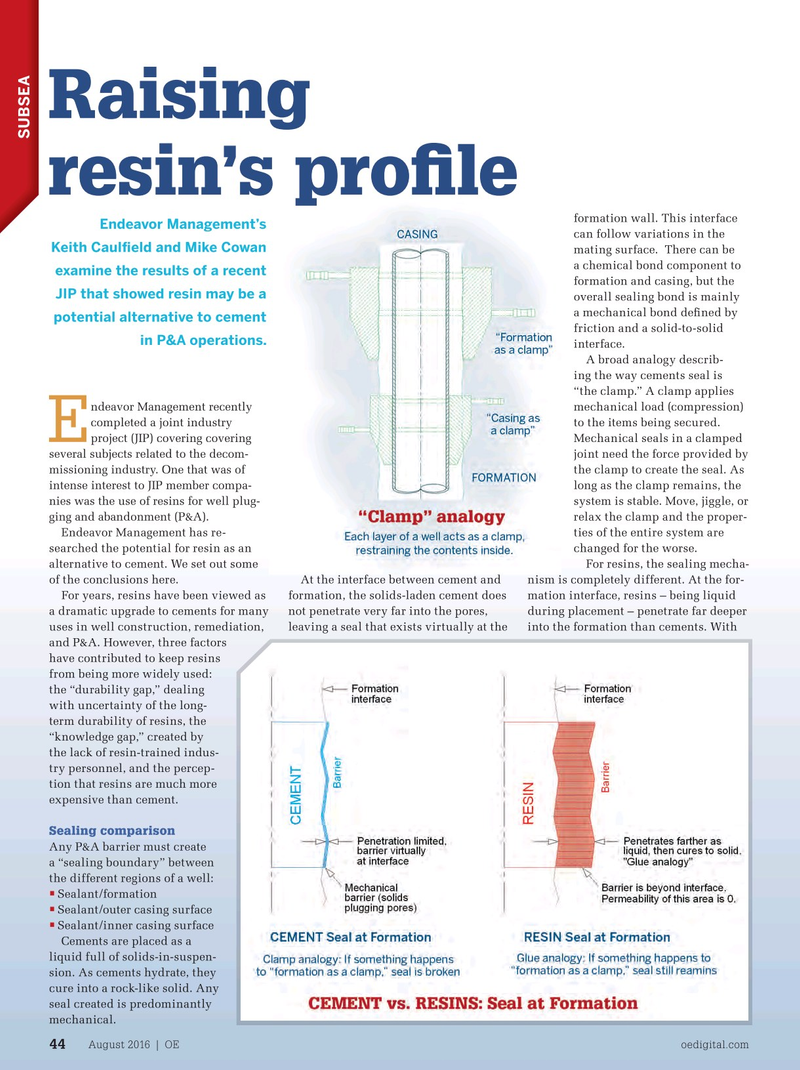

A broad analogy describ- ing the way cements seal is “the clamp.” A clamp applies ndeavor Management recently mechanical load (compression) completed a joint industry to the items being secured.

E project (JIP) covering covering Mechanical seals in a clamped several subjects related to the decom- joint need the force provided by missioning industry. One that was of the clamp to create the seal. As intense interest to JIP member compa- long as the clamp remains, the nies was the use of resins for well plug- system is stable. Move, jiggle, or ging and abandonment (P&A). relax the clamp and the proper-

Endeavor Management has re- ties of the entire system are searched the potential for resin as an changed for the worse.

alternative to cement. We set out some For resins, the sealing mecha-

At the interface between cement and of the conclusions here. nism is completely different. At the for- formation, the solids-laden cement does For years, resins have been viewed as mation interface, resins – being liquid not penetrate very far into the pores, a dramatic upgrade to cements for many during placement – penetrate far deeper leaving a seal that exists virtually at the uses in well construction, remediation, into the formation than cements. With and P&A. However, three factors have contributed to keep resins from being more widely used: the “durability gap,” dealing with uncertainty of the long- term durability of resins, the “knowledge gap,” created by the lack of resin-trained indus- try personnel, and the percep- tion that resins are much more expensive than cement.

Sealing comparison

Any P&A barrier must create a “sealing boundary” between the different regions of a well: • Sealant/formation •

Sealant/outer casing surface •

Sealant/inner casing surface

Cements are placed as a liquid full of solids-in-suspen- sion. As cements hydrate, they cure into a rock-like solid. Any seal created is predominantly mechanical.

August 2016 | OE oedigital.com 44 044_OE0816_Subsea4_JIP.indd 44 7/24/16 3:18 PM

41

41

43

43