Page 43: of Offshore Engineer Magazine (Aug/Sep 2016)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2016 Offshore Engineer Magazine

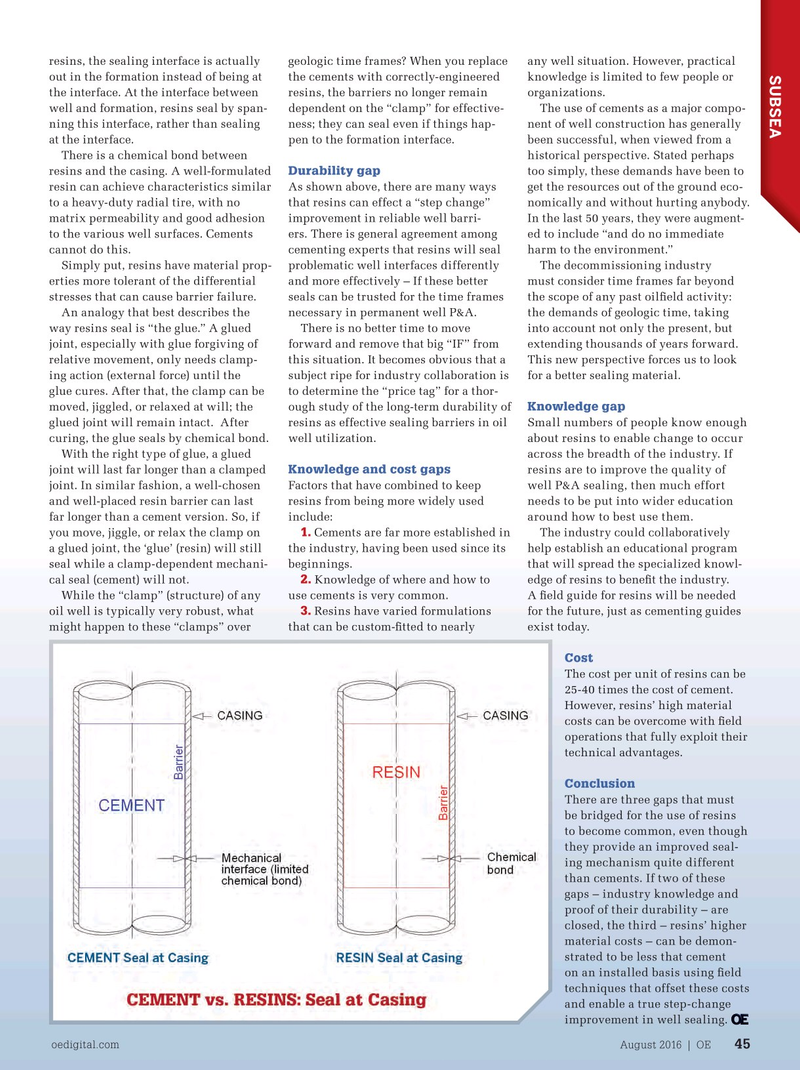

resins, the sealing interface is actually geologic time frames? When you replace any well situation. However, practical

SUBSEA out in the formation instead of being at the cements with correctly-engineered knowledge is limited to few people or the interface. At the interface between resins, the barriers no longer remain organizations.

well and formation, resins seal by span- dependent on the “clamp” for effective- The use of cements as a major compo- ning this interface, rather than sealing ness; they can seal even if things hap- nent of well construction has generally at the interface. pen to the formation interface. been successful, when viewed from a

There is a chemical bond between historical perspective. Stated perhaps

Durability gap resins and the casing. A well-formulated too simply, these demands have been to resin can achieve characteristics similar As shown above, there are many ways get the resources out of the ground eco- to a heavy-duty radial tire, with no that resins can effect a “step change” nomically and without hurting anybody. matrix permeability and good adhesion improvement in reliable well barri- In the last 50 years, they were augment- to the various well surfaces. Cements ers. There is general agreement among ed to include “and do no immediate cannot do this. cementing experts that resins will seal harm to the environment.”

Simply put, resins have material prop- problematic well interfaces differently The decommissioning industry erties more tolerant of the differential and more effectively – If these better must consider time frames far beyond stresses that can cause barrier failure. seals can be trusted for the time frames the scope of any past oil? eld activity:

An analogy that best describes the necessary in permanent well P&A. the demands of geologic time, taking way resins seal is “the glue.” A glued There is no better time to move into account not only the present, but joint, especially with glue forgiving of forward and remove that big “IF” from extending thousands of years forward. relative movement, only needs clamp- this situation. It becomes obvious that a This new perspective forces us to look ing action (external force) until the subject ripe for industry collaboration is for a better sealing material.

glue cures. After that, the clamp can be to determine the “price tag” for a thor-

Knowledge gap moved, jiggled, or relaxed at will; the ough study of the long-term durability of

Small numbers of people know enough glued joint will remain intact. After resins as effective sealing barriers in oil about resins to enable change to occur curing, the glue seals by chemical bond. well utilization. across the breadth of the industry. If

With the right type of glue, a glued

Knowledge and cost gaps resins are to improve the quality of joint will last far longer than a clamped well P&A sealing, then much effort joint. In similar fashion, a well-chosen Factors that have combined to keep needs to be put into wider education and well-placed resin barrier can last resins from being more widely used around how to best use them. far longer than a cement version. So, if include: 1.

you move, jiggle, or relax the clamp on Cements are far more established in The industry could collaboratively a glued joint, the ‘glue’ (resin) will still the industry, having been used since its help establish an educational program seal while a clamp-dependent mechani- beginnings. that will spread the specialized knowl- 2.

cal seal (cement) will not. Knowledge of where and how to edge of resins to bene? t the industry.

While the “clamp” (structure) of any use cements is very common. A ? eld guide for resins will be needed 3.

oil well is typically very robust, what Resins have varied formulations for the future, just as cementing guides might happen to these “clamps” over that can be custom-? tted to nearly exist today.

Cost

The cost per unit of resins can be 25-40 times the cost of cement.

However, resins’ high material costs can be overcome with ? eld operations that fully exploit their technical advantages.

Conclusion

There are three gaps that must be bridged for the use of resins to become common, even though they provide an improved seal- ing mechanism quite different than cements. If two of these gaps – industry knowledge and proof of their durability – are closed, the third – resins’ higher material costs – can be demon- strated to be less that cement on an installed basis using ? eld techniques that offset these costs and enable a true step-change improvement in well sealing. oedigital.com August 2016 | OE 45 044_OE0816_Subsea4_JIP.indd 45 7/24/16 3:17 PM

42

42

44

44