Page 31: of Offshore Engineer Magazine (May/Jun 2019)

Offshore Renewables Review

Read this page in Pdf, Flash or Html5 edition of May/Jun 2019 Offshore Engineer Magazine

depending on turbine and cable costs.

That doesn’t mean there aren’t headwinds. Over the last 18 months, Quest FWE had to remove or set back the date for 20%

FLOATING SUBSTATION of the projects it tracks, most of which were demonstrators that proved too hard to ? nance. “There is considerable interest from

DESIGNS TAKE SHAPE the ? nancial community, however,” he adds, “and it is believed that with each project coming online successfully, and the more

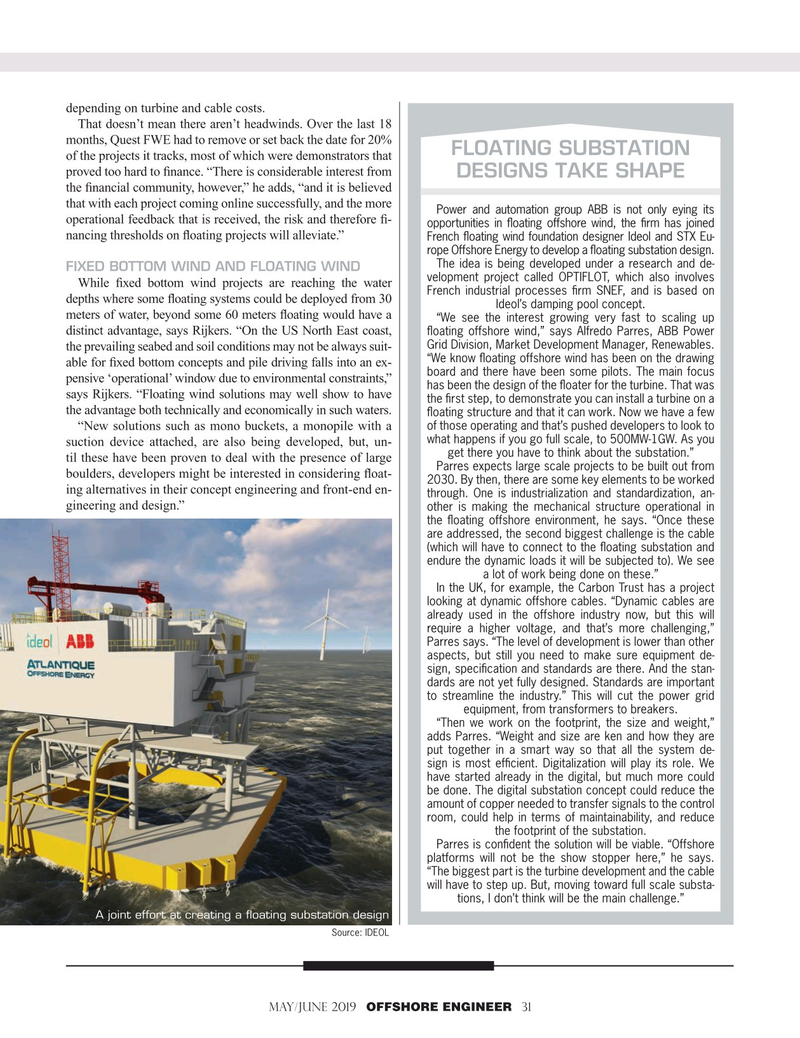

Power and automation group ABB is not only eying its operational feedback that is received, the risk and therefore ? - opportunities in ? oating offshore wind, the ? rm has joined nancing thresholds on ? oating projects will alleviate.”

French ? oating wind foundation designer Ideol and STX Eu- rope Offshore Energy to develop a ? oating substation design.

The idea is being developed under a research and de-

FIXED BOTTOM WIND AND FLOATING WIND velopment project called OPTIFLOT, which also involves

While ? xed bottom wind projects are reaching the water

French industrial processes ? rm SNEF, and is based on depths where some ? oating systems could be deployed from 30

Ideol’s damping pool concept.

meters of water, beyond some 60 meters ? oating would have a “We see the interest growing very fast to scaling up distinct advantage, says Rijkers. “On the US North East coast, ? oating offshore wind,” says Alfredo Parres, ABB Power

Grid Division, Market Development Manager, Renewables. the prevailing seabed and soil conditions may not be always suit- “We know ? oating offshore wind has been on the drawing able for ? xed bottom concepts and pile driving falls into an ex- board and there have been some pilots. The main focus pensive ‘operational’ window due to environmental constraints,” has been the design of the ? oater for the turbine. That was says Rijkers. “Floating wind solutions may well show to have the ? rst step, to demonstrate you can install a turbine on a the advantage both technically and economically in such waters. ? oating structure and that it can work. Now we have a few of those operating and that’s pushed developers to look to “New solutions such as mono buckets, a monopile with a what happens if you go full scale, to 500MW-1GW. As you suction device attached, are also being developed, but, un- get there you have to think about the substation.” til these have been proven to deal with the presence of large

Parres expects large scale projects to be built out from boulders, developers might be interested in considering ? oat- 2030. By then, there are some key elements to be worked ing alternatives in their concept engineering and front-end en- through. One is industrialization and standardization, an- gineering and design.” other is making the mechanical structure operational in the ? oating offshore environment, he says. “Once these are addressed, the second biggest challenge is the cable (which will have to connect to the ? oating substation and endure the dynamic loads it will be subjected to). We see a lot of work being done on these.”

In the UK, for example, the Carbon Trust has a project looking at dynamic offshore cables. “Dynamic cables are already used in the offshore industry now, but this will require a higher voltage, and that’s more challenging,”

Parres says. “The level of development is lower than other aspects, but still you need to make sure equipment de- sign, speci? cation and standards are there. And the stan- dards are not yet fully designed. Standards are important to streamline the industry.” This will cut the power grid equipment, from transformers to breakers.

“Then we work on the footprint, the size and weight,” adds Parres. “Weight and size are ken and how they are put together in a smart way so that all the system de- sign is most ef? cient. Digitalization will play its role. We have started already in the digital, but much more could be done. The digital substation concept could reduce the amount of copper needed to transfer signals to the control room, could help in terms of maintainability, and reduce the footprint of the substation.

Parres is con? dent the solution will be viable. “Offshore platforms will not be the show stopper here,” he says. “The biggest part is the turbine development and the cable will have to step up. But, moving toward full scale substa- tions, I don’t think will be the main challenge.”

A joint effort at creating a floating substation design

Source: IDEOL

MaY/JUNE 2019 OFFSHORE ENGINEER 31

30

30

32

32