Page 53: of Offshore Engineer Magazine (Jul/Aug 2019)

Subsea Processing

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2019 Offshore Engineer Magazine

TECH FILES Walk to Work ters signi? cant wave height and transfer 20 people in under normally unmanned installation. Around 100 workers have ? ve minutes from a vessel to a ? xed or ? oating object. It is been safely transferred from the vessel to the platform, with suited to a wide range of applications and was recently mo- more than 1,300 crossing successfully completed during the bilized on a Micoperi multipurpose support vessel (MPSV) ? rst hook-up phase, which lasted nine days.

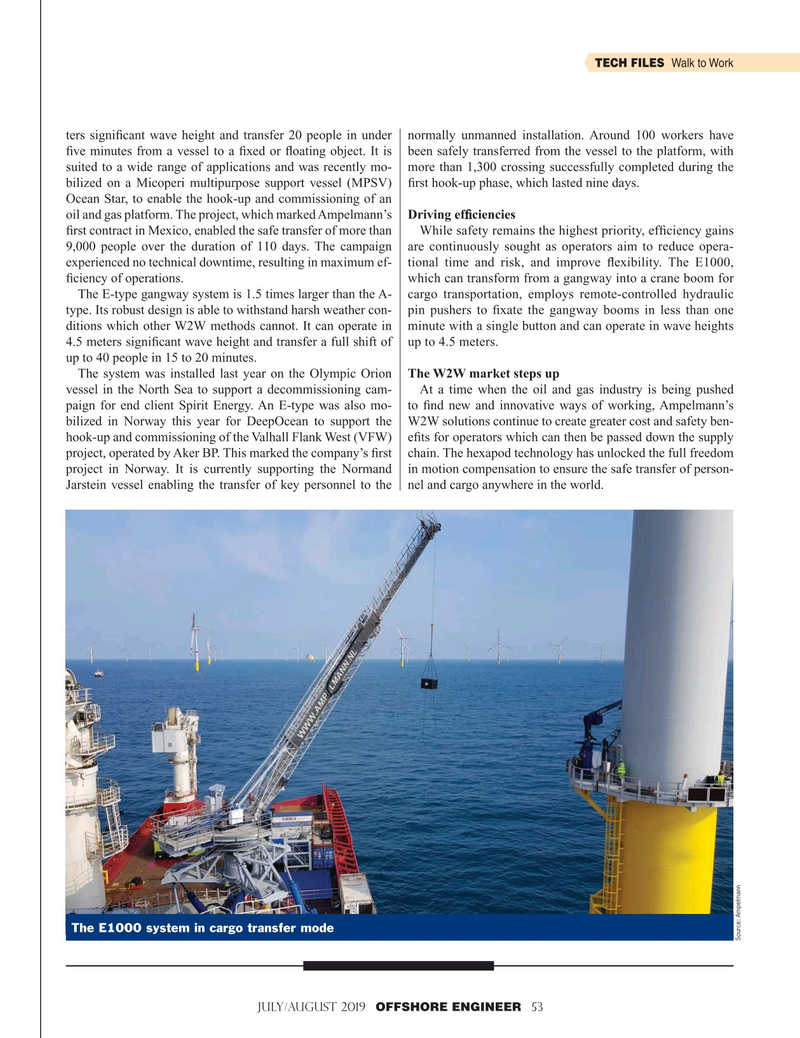

Ocean Star, to enable the hook-up and commissioning of an oil and gas platform. The project, which marked Ampelmann’s Driving ef? ciencies ? rst contract in Mexico, enabled the safe transfer of more than While safety remains the highest priority, ef? ciency gains 9,000 people over the duration of 110 days. The campaign are continuously sought as operators aim to reduce opera- experienced no technical downtime, resulting in maximum ef- tional time and risk, and improve ? exibility. The E1000, ? ciency of operations. which can transform from a gangway into a crane boom for

The E-type gangway system is 1.5 times larger than the A- cargo transportation, employs remote-controlled hydraulic type. Its robust design is able to withstand harsh weather con- pin pushers to ? xate the gangway booms in less than one ditions which other W2W methods cannot. It can operate in minute with a single button and can operate in wave heights 4.5 meters signi? cant wave height and transfer a full shift of up to 4.5 meters.

up to 40 people in 15 to 20 minutes.

The system was installed last year on the Olympic Orion The W2W market steps up vessel in the North Sea to support a decommissioning cam- At a time when the oil and gas industry is being pushed paign for end client Spirit Energy. An E-type was also mo- to ? nd new and innovative ways of working, Ampelmann’s bilized in Norway this year for DeepOcean to support the W2W solutions continue to create greater cost and safety ben- hook-up and commissioning of the Valhall Flank West (VFW) e? ts for operators which can then be passed down the supply project, operated by Aker BP. This marked the company’s ? rst chain. The hexapod technology has unlocked the full freedom project in Norway. It is currently supporting the Normand in motion compensation to ensure the safe transfer of person-

Jarstein vessel enabling the transfer of key personnel to the nel and cargo anywhere in the world.

The E1000 system in cargo transfer mode

Source: Ampelmann

JULY/AUGUST 2019 OFFSHORE ENGINEER 53

52

52

54

54