Page 48: of Offshore Engineer Magazine (Sep/Oct 2021)

Digital Transformation

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2021 Offshore Engineer Magazine

PRODUCTS POWER GENERATION

Methanol, Batteries for WTIV shore the north-western coast of Australia, at water depths of approximately 1,400 meters.

The project will involve constructing and installing a 27,000-ton (Topside and Hull) normally unattended foat- ing Field Control Station (FCS), approximately 6,500 tons of subsea compression infrastructure, and a 135km submarine power cable linked to Barrow Island.

ABB will provide the majority of the electrical equipment, both topside and subsea, for J-IC. The project will combine two core ABB technologies – power from shore and Variable

Speed Drive (VSD) long step-out subsea power – for the frst time. The electrical system will be designed to transmit 100 megavolt-amperes over a distance of approximately 140 km and at depths of 1,400 meters.

The contract was awarded following concept development and a front-end engineering and design (FEED) study. Work will start immediately, and the subsea compression system is expected to be in operation in 2025, ABB said.

ABB is working on a foating wind project too, through its

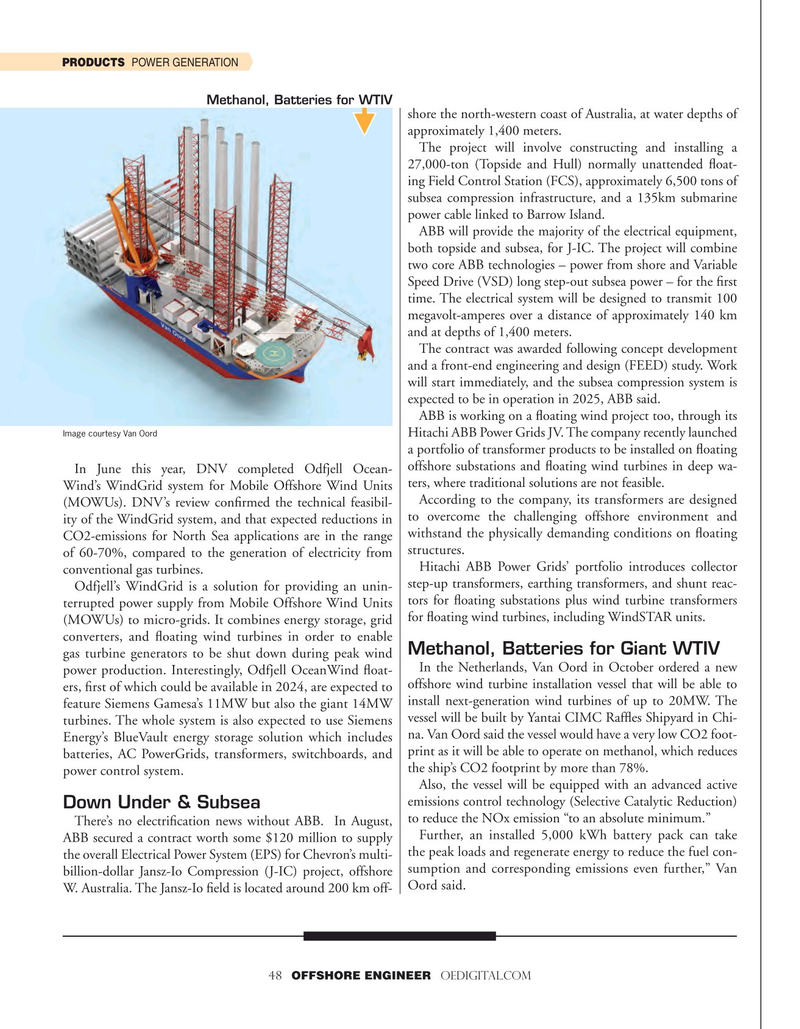

Image courtesy Van Oord

Hitachi ABB Power Grids JV. The company recently launched a portfolio of transformer products to be installed on foating offshore substations and foating wind turbines in deep wa-

In June this year, DNV completed Odfjell Ocean-

Wind’s WindGrid system for Mobile Offshore Wind Units ters, where traditional solutions are not feasible.

According to the company, its transformers are designed (MOWUs). DNV’s review confrmed the technical feasibil- ity of the WindGrid system, and that expected reductions in to overcome the challenging offshore environment and

CO2-emissions for North Sea applications are in the range withstand the physically demanding conditions on foating of 60-70%, compared to the generation of electricity from structures.

Hitachi ABB Power Grids’ portfolio introduces collector conventional gas turbines.

step-up transformers, earthing transformers, and shunt reac-

Odfjell’s WindGrid is a solution for providing an unin- terrupted power supply from Mobile Offshore Wind Units tors for foating substations plus wind turbine transformers (MOWUs) to micro-grids. It combines energy storage, grid for foating wind turbines, including WindSTAR units.

converters, and foating wind turbines in order to enable

Methanol, Batteries for Giant WTIV gas turbine generators to be shut down during peak wind

In the Netherlands, Van Oord in October ordered a new power production. Interestingly, Odfjell OceanWind foat- ers, frst of which could be available in 2024, are expected to offshore wind turbine installation vessel that will be able to feature Siemens Gamesa’s 11MW but also the giant 14MW install next-generation wind turbines of up to 20MW. The turbines. The whole system is also expected to use Siemens vessel will be built by Yantai CIMC Raffes Shipyard in Chi-

Energy’s BlueVault energy storage solution which includes na. Van Oord said the vessel would have a very low CO2 foot- batteries, AC PowerGrids, transformers, switchboards, and print as it will be able to operate on methanol, which reduces the ship’s CO2 footprint by more than 78%. power control system.

Also, the vessel will be equipped with an advanced active emissions control technology (Selective Catalytic Reduction)

Down Under & Subsea

There’s no electrifcation news without ABB. In August, to reduce the NOx emission “to an absolute minimum.”

Further, an installed 5,000 kWh battery pack can take

ABB secured a contract worth some $120 million to supply the peak loads and regenerate energy to reduce the fuel con- the overall Electrical Power System (EPS) for Chevron’s multi- billion-dollar Jansz-Io Compression (J-IC) project, offshore sumption and corresponding emissions even further,” Van

Oord said.

W. Australia. The Jansz-Io feld is located around 200 km off- 48 OFFSHORE ENGINEER OEDIGITAL.COM

47

47

3rd Cover

3rd Cover