Page 30: of Offshore Engineer Magazine (Mar/Apr 2022)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2022 Offshore Engineer Magazine

OFFSHORE WIND AI & ROBOTICS manned aerial vehicles (UAVs/drones) can’t spot. with plans for larger vehicles. However, it’s delivering “Drones are fantastic for a quick global inspection, to ? nd drones or blade crawling robots via USVs that many see as an area with problems, BladeBUG can then ascertain how se- offering a signi? cant opportunity.

rious they are or do the repairs,” says Cieslak. “We’re the next The Drone Swarm for Unmanned Inspection of Wind Tur- stage follow up inspection and [can] either repair or provide bines (Dr-SUIT for short) is aiming to deploy aerial drones more information to a repair specialist onshore, which means for offshore wind farm inspection from USVs. It is now being the rope access team can go and there won’t be any surprises.” led by Airborne Robotics with partners Ocean In? nity, the

The next goal is a repair module to perform cleaning University of Portsmouth, and Bentley Telecom. The group and sanding of areas before treatment. Imagine a power has said it plans to have a system demonstration in 2022. sander moved across the blade surface using the body of

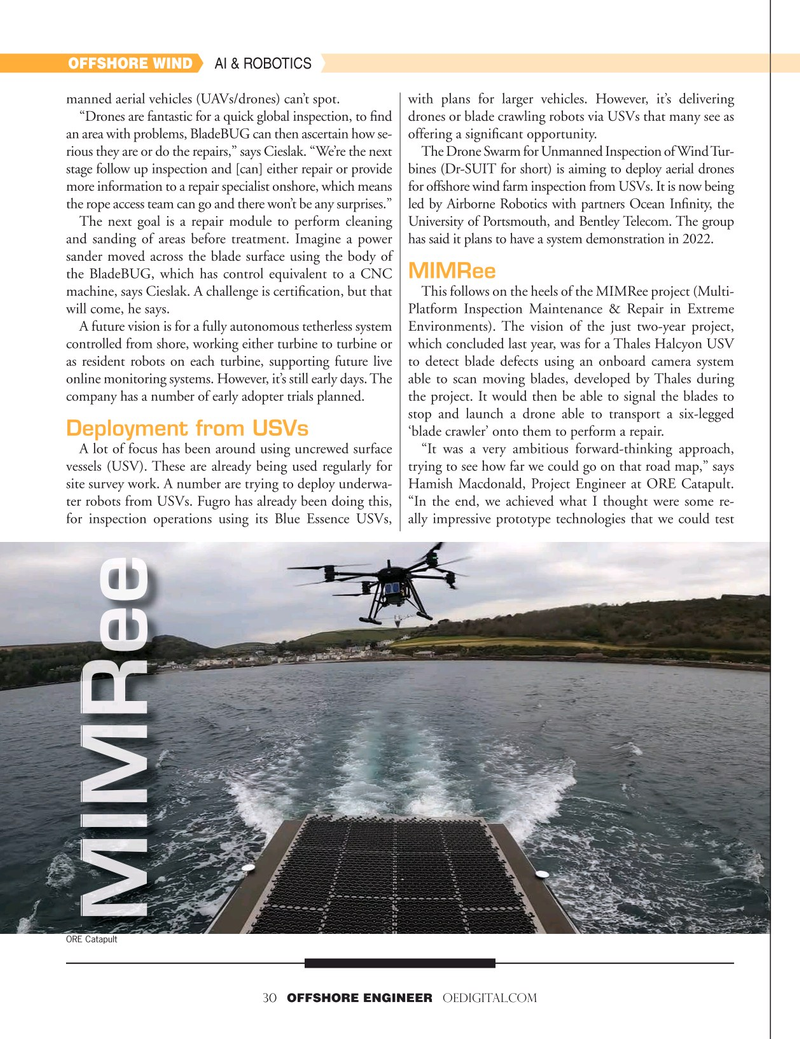

MIMRee the BladeBUG, which has control equivalent to a CNC machine, says Cieslak. A challenge is certi? cation, but that This follows on the heels of the MIMRee project (Multi- will come, he says. Platform Inspection Maintenance & Repair in Extreme

A future vision is for a fully autonomous tetherless system Environments). The vision of the just two-year project, controlled from shore, working either turbine to turbine or which concluded last year, was for a Thales Halcyon USV as resident robots on each turbine, supporting future live to detect blade defects using an onboard camera system online monitoring systems. However, it’s still early days. The able to scan moving blades, developed by Thales during company has a number of early adopter trials planned. the project. It would then be able to signal the blades to stop and launch a drone able to transport a six-legged

Deployment from USVs ‘blade crawler’ onto them to perform a repair.

A lot of focus has been around using uncrewed surface “It was a very ambitious forward-thinking approach, vessels (USV). These are already being used regularly for trying to see how far we could go on that road map,” says site survey work. A number are trying to deploy underwa- Hamish Macdonald, Project Engineer at ORE Catapult. ter robots from USVs. Fugro has already been doing this, “In the end, we achieved what I thought were some re- for inspection operations using its Blue Essence USVs, ally impressive prototype technologies that we could test

ORE Catapult 30 OFFSHORE ENGINEER OEDIGITAL.COM

29

29

31

31