Page 32: of Offshore Engineer Magazine (Mar/Apr 2024)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2024 Offshore Engineer Magazine

TECH FEATURE IMR

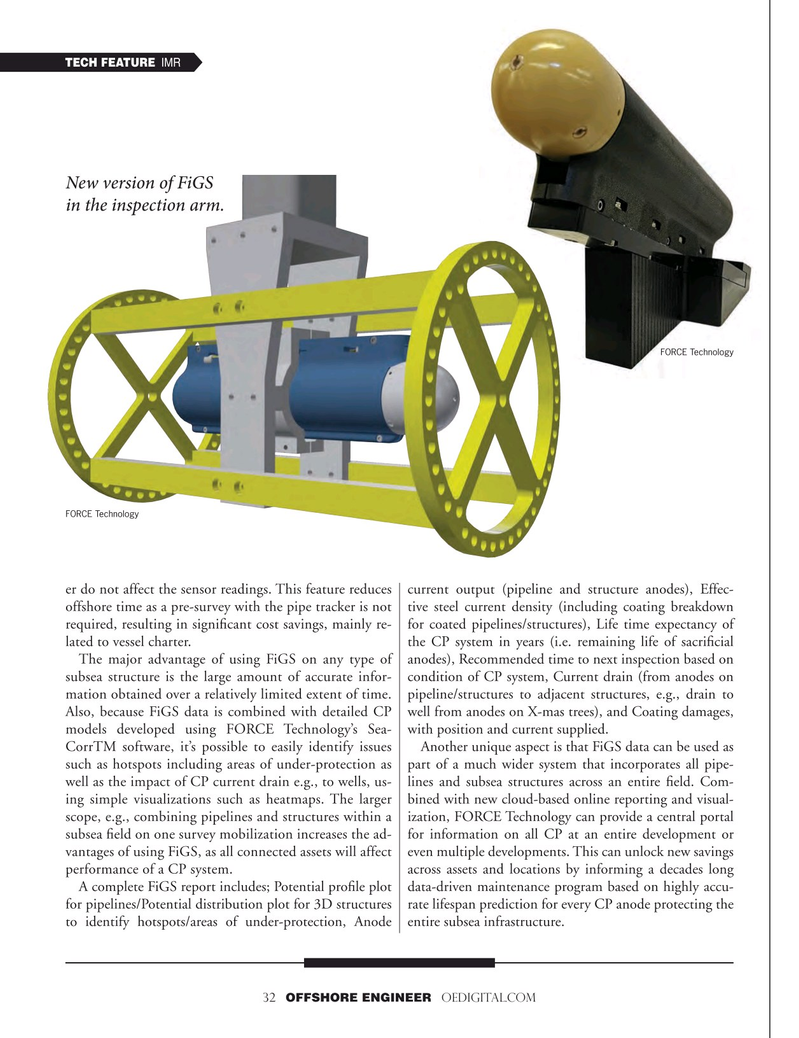

New version of FiGS in the inspection arm.

FORCE Technology

FORCE Technology er do not affect the sensor readings. This feature reduces current output (pipeline and structure anodes), Effec- offshore time as a pre-survey with the pipe tracker is not tive steel current density (including coating breakdown required, resulting in signifcant cost savings, mainly re- for coated pipelines/structures), Life time expectancy of lated to vessel charter. the CP system in years (i.e. remaining life of sacrifcial

The major advantage of using FiGS on any type of anodes), Recommended time to next inspection based on subsea structure is the large amount of accurate infor- condition of CP system, Current drain (from anodes on mation obtained over a relatively limited extent of time. pipeline/structures to adjacent structures, e.g., drain to

Also, because FiGS data is combined with detailed CP well from anodes on X-mas trees), and Coating damages, models developed using FORCE Technology’s Sea- with position and current supplied.

CorrTM software, it’s possible to easily identify issues Another unique aspect is that FiGS data can be used as such as hotspots including areas of under-protection as part of a much wider system that incorporates all pipe- well as the impact of CP current drain e.g., to wells, us- lines and subsea structures across an entire feld. Com- ing simple visualizations such as heatmaps. The larger bined with new cloud-based online reporting and visual- scope, e.g., combining pipelines and structures within a ization, FORCE Technology can provide a central portal subsea feld on one survey mobilization increases the ad- for information on all CP at an entire development or vantages of using FiGS, as all connected assets will affect even multiple developments. This can unlock new savings performance of a CP system. across assets and locations by informing a decades long

A complete FiGS report includes; Potential profle plot data-driven maintenance program based on highly accu- for pipelines/Potential distribution plot for 3D structures rate lifespan prediction for every CP anode protecting the to identify hotspots/areas of under-protection, Anode entire subsea infrastructure.

32 OFFSHORE ENGINEER OEDIGITAL.COM

31

31

33

33