Page 11: of Offshore Engineer Magazine (May/Jun 2024)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2024 Offshore Engineer Magazine

s offshore oil and gas infrastructure ages and the ever-present risk posed by equipment failure looms, new solutions are required to help keep

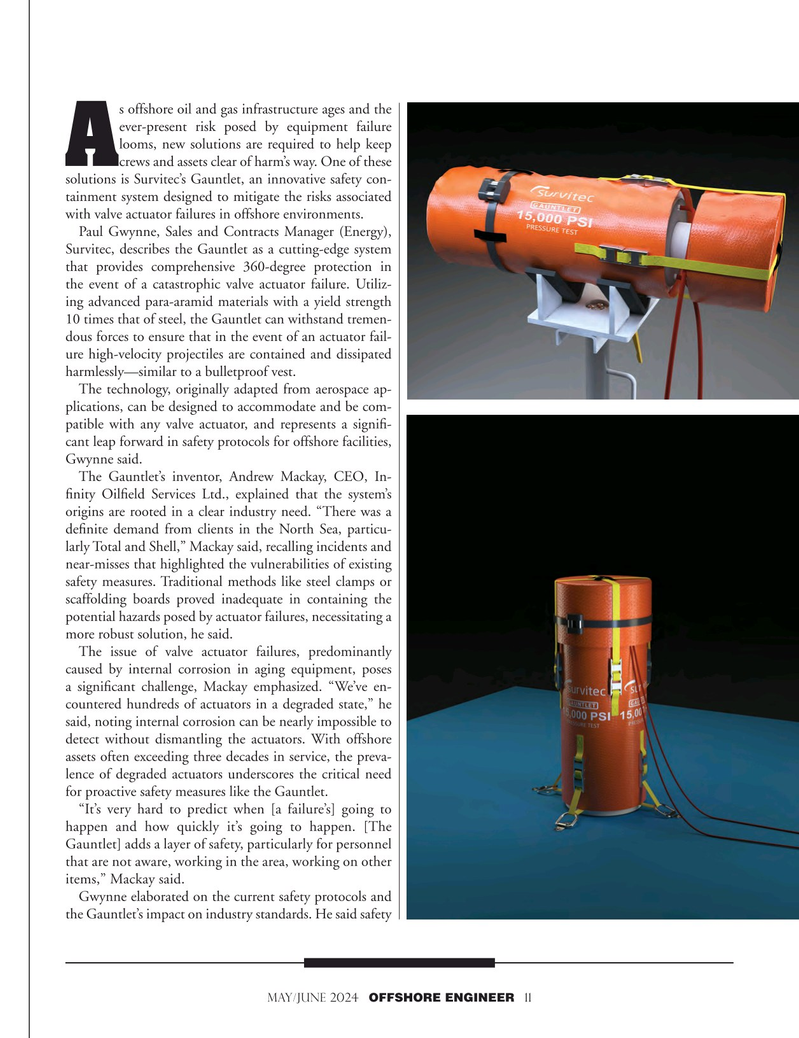

A crews and assets clear of harm’s way. One of these solutions is Survitec’s Gauntlet, an innovative safety con- tainment system designed to mitigate the risks associated with valve actuator failures in offshore environments.

Paul Gwynne, Sales and Contracts Manager (Energy),

Survitec, describes the Gauntlet as a cutting-edge system that provides comprehensive 360-degree protection in the event of a catastrophic valve actuator failure. Utiliz- ing advanced para-aramid materials with a yield strength 10 times that of steel, the Gauntlet can withstand tremen- dous forces to ensure that in the event of an actuator fail- ure high-velocity projectiles are contained and dissipated harmlessly—similar to a bulletproof vest.

The technology, originally adapted from aerospace ap- plications, can be designed to accommodate and be com- patible with any valve actuator, and represents a signif- cant leap forward in safety protocols for offshore facilities,

Gwynne said.

The Gauntlet’s inventor, Andrew Mackay, CEO, In- fnity Oilfeld Services Ltd., explained that the system’s origins are rooted in a clear industry need. “There was a defnite demand from clients in the North Sea, particu- larly Total and Shell,” Mackay said, recalling incidents and near-misses that highlighted the vulnerabilities of existing safety measures. Traditional methods like steel clamps or scaffolding boards proved inadequate in containing the potential hazards posed by actuator failures, necessitating a more robust solution, he said.

The issue of valve actuator failures, predominantly caused by internal corrosion in aging equipment, poses a signifcant challenge, Mackay emphasized. “We’ve en- countered hundreds of actuators in a degraded state,” he said, noting internal corrosion can be nearly impossible to detect without dismantling the actuators. With offshore assets often exceeding three decades in service, the preva- lence of degraded actuators underscores the critical need for proactive safety measures like the Gauntlet.

“It’s very hard to predict when [a failure’s] going to happen and how quickly it’s going to happen. [The

Gauntlet] adds a layer of safety, particularly for personnel that are not aware, working in the area, working on other items,” Mackay said.

Gwynne elaborated on the current safety protocols and the Gauntlet’s impact on industry standards. He said safety

MAy/june 2024 OFFSHORE ENGINEER 11

10

10

12

12