Page 57: of Offshore Engineer Magazine (Sep/Oct 2024)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2024 Offshore Engineer Magazine

he AOGV technology has proved its capabilities over the seven years that have passed since the initial operation, on the Goliat installation in the

T

Barents Sea. Since then, Izomax has delivered a total of 200 operations worldwide that have caught the eye of the energy sector. This summer, Izomax signed a three- year global frame agreement with Shell. The supermajor has ambitions to use AOGV to reinvent their maintenance practices and introduce predictive maintenance measures to reduce downtime and unplanned outages while main- taining revenue streams.

In this article, I will highlight two case studies proving the versatility of the AOGV system and give a short ac- count of the R&D process.

Developing the AOGV

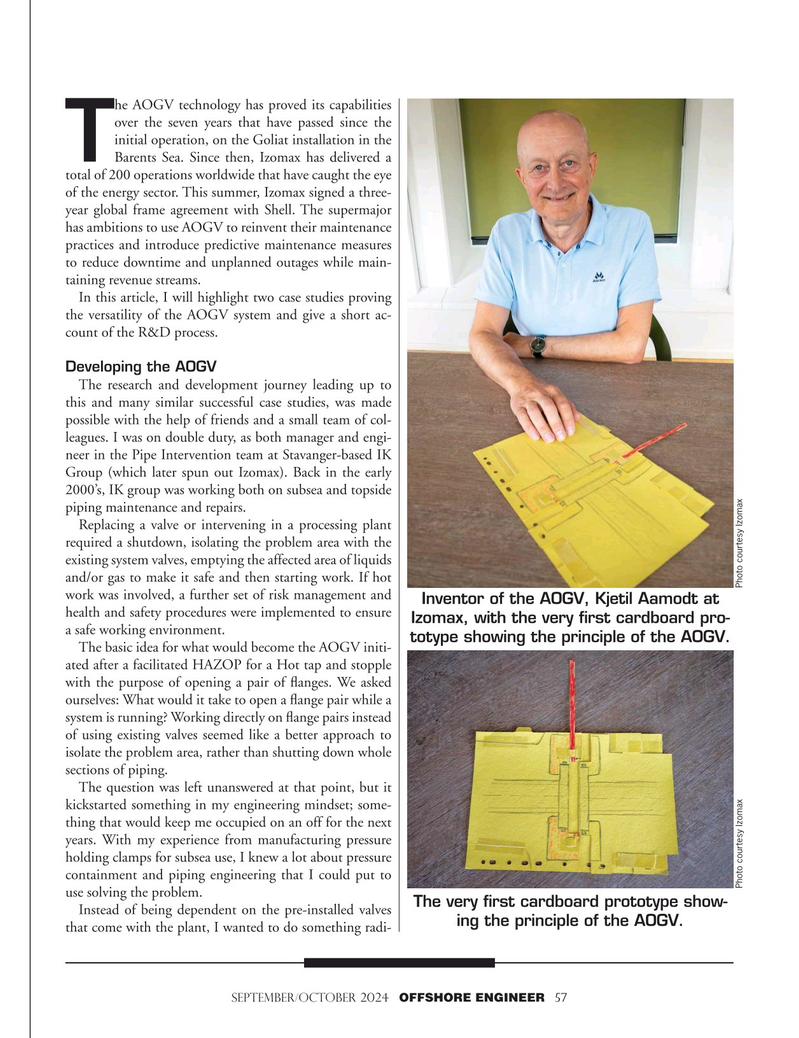

The research and development journey leading up to this and many similar successful case studies, was made possible with the help of friends and a small team of col- leagues. I was on double duty, as both manager and engi- neer in the Pipe Intervention team at Stavanger-based IK

Group (which later spun out Izomax). Back in the early 2000’s, IK group was working both on subsea and topside piping maintenance and repairs.

Replacing a valve or intervening in a processing plant required a shutdown, isolating the problem area with the existing system valves, emptying the affected area of liquids and/or gas to make it safe and then starting work. If hot work was involved, a further set of risk management and

Inventor of the AOGV, Kjetil Aamodt at health and safety procedures were implemented to ensure

Izomax, with the very first cardboard pro- a safe working environment.

totype showing the principle of the AOGV.

The basic idea for what would become the AOGV initi- ated after a facilitated HAZOP for a Hot tap and stopple with the purpose of opening a pair of ?anges. We asked ourselves: What would it take to open a ?ange pair while a system is running? Working directly on ?ange pairs instead of using existing valves seemed like a better approach to isolate the problem area, rather than shutting down whole sections of piping.

The question was left unanswered at that point, but it kickstarted something in my engineering mindset; some- thing that would keep me occupied on an off for the next years. With my experience from manufacturing pressure holding clamps for subsea use, I knew a lot about pressure containment and piping engineering that I could put to

Photo courtesy IzomaxPhoto courtesy Izomax use solving the problem.

The very first cardboard prototype show-

Instead of being dependent on the pre-installed valves ing the principle of the AOGV. that come with the plant, I wanted to do something radi- september/october 2024 OFFSHORE ENGINEER 57

56

56

58

58