Page 38: of Offshore Engineer Magazine (Jan/Feb 2025)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2025 Offshore Engineer Magazine

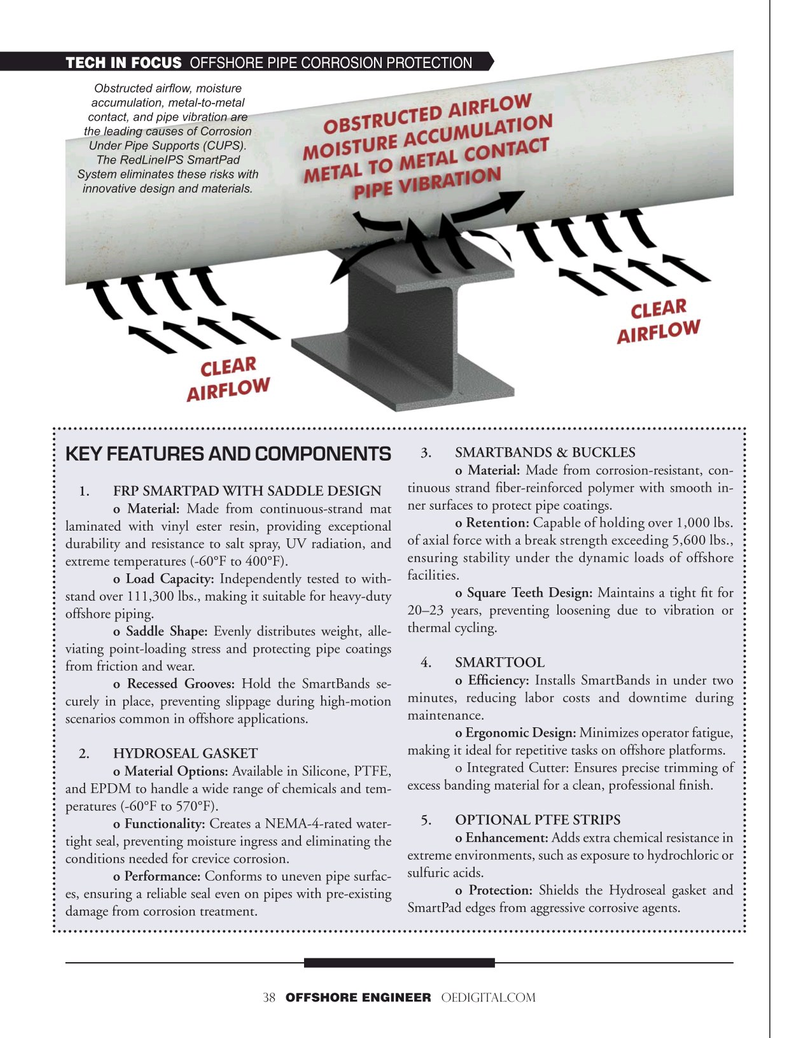

TECH IN FOCUS OFFSHORE PIPE CORROSION PROTECTION accumulation, metal-to-metal contact, and pipe vibration are the leading causes of Corrosion

Under Pipe Supports (CUPS).

The RedLineIPS SmartPad

System eliminates these risks with innovative design and materials.

3. SMARTBANDS & BUCKLES

KEY FEATURES AND COMPONENTS o Material: Made from corrosion-resistant, con- tinuous strand ?ber-reinforced polymer with smooth in- 1. FRP SMARTPAD WITH SADDLE DESIGN o Material: Made from continuous-strand mat ner surfaces to protect pipe coatings.

o Retention: Capable of holding over 1,000 lbs. laminated with vinyl ester resin, providing exceptional durability and resistance to salt spray, UV radiation, and of axial force with a break strength exceeding 5,600 lbs., ensuring stability under the dynamic loads of offshore extreme temperatures (-60°F to 400°F).

facilities.

o Load Capacity: Independently tested to with- o Square Teeth Design: Maintains a tight ?t for stand over 111,300 lbs., making it suitable for heavy-duty 20–23 years, preventing loosening due to vibration or offshore piping.

thermal cycling.

o Saddle Shape: Evenly distributes weight, alle- viating point-loading stress and protecting pipe coatings 4. SMARTTOOL from friction and wear.

o Ef?ciency: Installs SmartBands in under two o Recessed Grooves: Hold the SmartBands se- curely in place, preventing slippage during high-motion minutes, reducing labor costs and downtime during maintenance.

scenarios common in offshore applications.

o Ergonomic Design: Minimizes operator fatigue, making it ideal for repetitive tasks on offshore platforms.

2. HYDROSEAL GASKET o Integrated Cutter: Ensures precise trimming of o Material Options: Available in Silicone, PTFE, excess banding material for a clean, professional ?nish.

and EPDM to handle a wide range of chemicals and tem- peratures (-60°F to 570°F).

5. OPTIONAL PTFE STRIPS o Functionality: Creates a NEMA-4-rated water- o Enhancement: Adds extra chemical resistance in tight seal, preventing moisture ingress and eliminating the extreme environments, such as exposure to hydrochloric or conditions needed for crevice corrosion.

sulfuric acids.

o Performance: Conforms to uneven pipe surfac- o Protection: Shields the Hydroseal gasket and es, ensuring a reliable seal even on pipes with pre-existing

SmartPad edges from aggressive corrosive agents.

damage from corrosion treatment.

38 OFFSHORE ENGINEER OEDIGITAL.COM

37

37

39

39