Page 39: of Offshore Engineer Magazine (Jan/Feb 2025)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2025 Offshore Engineer Magazine

HOW THE SMARTPAD SYSTEM MITIGATES OFFSHORE CORROSION 1. PREVENTS GALVANIC CORROSION o The non-metallic FRP construction eliminates metal-to-metal contact, breaking the electrochemical circuit that causes galvanic corrosion in saltwater environments.

2. ELIMINATES CREVICE CORROSION o The Hydroseal gasket blocks moisture from entering the pipe/pad interface, preventing the water pooling that fosters crevice corrosion.

3. IMPROVES AIRFLOW o The saddle design elevates the pipe above the support, enhancing air?ow and promoting evaporation, further reducing the risk of moisture retention.

4. FACILITATES PROACTIVE MAINTENANCE o The system’s quick removal and reinstallation enable rapid visual inspections, reducing reliance on costly meth- ods like radiography or ultrasound. This improves the ability to detect early signs of corrosion and address them promptly.

5. REDUCES MECHANICAL STRESS o The saddle shape evenly distributes pipe loads, eliminating point-loading stress that could otherwise lead to coating failure and localized corrosion.

Advantages for Offshore Applications

Compared to conventional solutions like welded me- tallic supports or epoxied FRP pads, the SmartPad Sys- tem offers unique advantages tailored to offshore and coastal environments:

UÊCorrosion Resistance: Built to withstand harsh ma- rine environments with high salt exposure and humidity.

UÊInstallation Speed: Installs in under two minutes without welding, epoxy, or line shutdowns, drastically re- ducing downtime.

UÊVersatility: Suitable for pipes from ½” to 72” in di- ameter, making it adaptable for diverse piping needs on offshore platforms.

UÊDurability: UV-stable and long-lasting materials en- sure reliable performance for 20–30 years, even in extreme conditions.

UÊCost Ef?ciency: Eliminates the need for expensive welding permits, skilled labor, and prolonged maintenance schedules.

UÊSustainability: Reusable components promote sus- tainability and reduce waste, aligning with green initiatives in maritime industries.

Applications in Offshore and

Coastal Facilities

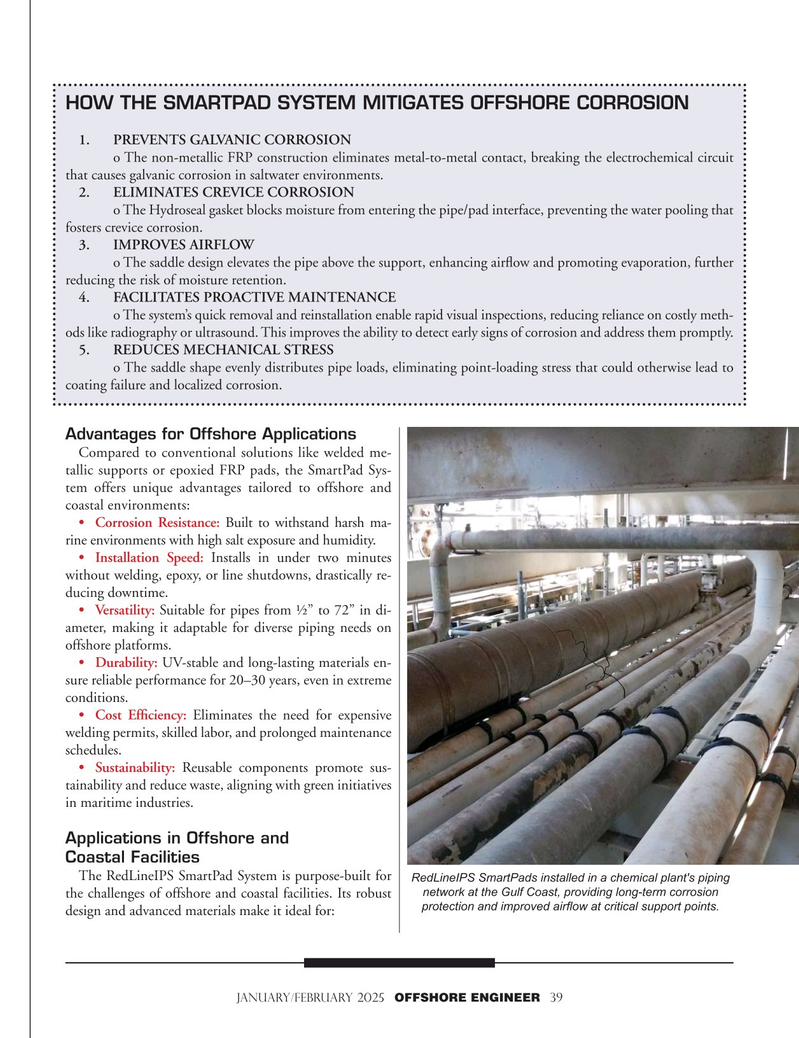

The RedLineIPS SmartPad System is purpose-built for

RedLineIPS SmartPads installed in a chemical plant's piping network at the Gulf Coast, providing long-term corrosion the challenges of offshore and coastal facilities. Its robust design and advanced materials make it ideal for: january/february 2025 OFFSHORE ENGINEER 39

38

38

40

40