North River Boats Thrives in a Challenging Build Market

By Joseph Keefe

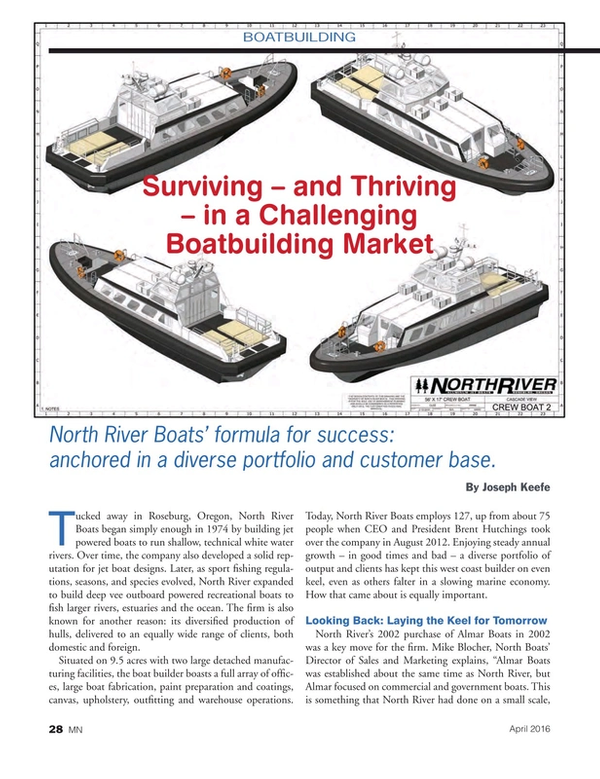

North River Boats’ formula for success: anchored in a diverse portfolio and customer base.

Tucked away in Roseburg, Ore., North River Boats began simply enough in 1974 by building jet powered boats to run shallow, technical white water rivers. Over time, the company also developed a solid reputation for jet boat designs. Later, as sport fishing regulations, seasons, and species evolved, North River expanded to build deep vee outboard powered recreational boats to fish larger rivers, estuaries and the ocean. The firm is also known for another reason: its diversified production of hulls, delivered to an equally wide range of clients, both domestic and foreign.

Situated on 9.5 acres with two large detached manufacturing facilities, the boat builder boasts a full array of offices, large boat fabrication, paint preparation and coatings, canvas, upholstery, outfitting and warehouse operations. Today, North River Boats employs 127, up from about 75 people when CEO and President Brent Hutchings took over the company in August 2012. Enjoying steady annual growth – in good times and bad – a diverse portfolio of output and clients has kept this west coast builder on even keel, even as others falter in a slowing marine economy. How that came about is equally important.

Looking Back: Laying the Keel for Tomorrow

North River’s 2002 purchase of Almar Boats in 2002 was a key move for the firm. Mike Blocher, North Boats’ Director of Sales and Marketing explains, “Almar Boats was established about the same time as North River, but Almar focused on commercial and government boats. This is something that North River had done on a small scale, but Almar dramatically broadened North River’s capabilities into complex workboats. Both factories remained open until the beginning of 2008 when Almar was absorbed into the North River Boats factory in Roseburg.”

Coming quickly up to speed on the complexities of the commercial and government boat world, North River then began building on the original Almar designs and expanding their portfolio diversity in terms of vessel sizes and types. Today, the firm’s business split is about 40 percent commercial/government boats and 60 percent recreational boats. The largest boat delivered to date is a Crew Transport vessel delivered to Trinidad & Tobago that – 52 feet LOA – equipped with twin diesel waterjets. Blocher adds, “This is soon to be surpassed, as we are designing a 56.5’ x 17’ crew transport vessel that will be delivered by the end of the year.”

Diverse Portfolio

In addition to as many as eight different recreational models that are sold through a dealer network, North River is capable of building more than 40 commercial boats annually. Building everything from charter fishing boats, U.S. Coast Guard Sub Chapter T Passenger Inspected boats, Hydrographic Survey boats, Law Enforcement and Patrol, Fire Rescue, Vessel Assist and for the U.S. Navy, North River’s reach into almost every aspect of the workboat market is deep.

But Blocher says that the variety and number of North River’s customers is just as important. “Our customer base is as diverse as our boat portfolio. One of the things that set us apart from other commercial boat builders is our ability to efficiently design and build one-off products. Many of our competitors go after large government contracts that have multi-year IDIQ delivery orders. We have done a great job at going after the one to 10 boat contracts. We are able to deliver world-class products to a broader customer base.”

Buying a North River Boat can also include training and re-activation on commercial and government models. “We always conduct the re-activation on every vessel. This is to ensure proper delivery and set-up of the boat prior to it going into service. These are expensive boats and it is our responsibility to make sure the boat is functioning properly before putting it into service,” said Blocher.

Although the recreational market remains North River’s largest in terms of revenue, Blocher says the firm remains committed to not having more than a small percentage of our business with any one customer. “Although the recreational market is a large part of our business, we have many dealers within that market. This gives us the flexibility to adjust depending on how each market segment is doing. Our recreational business is sold out through our dealer network until the model year change in August with steady growth expected for the 2017 model year.” In 2016 alone, North River will produce as many as 325 recreational hulls. But, he adds, “The commercial market remains very strong for us. We are growing both internationally and with private commercial customers and staying steady with government work. We have a solid backlog with only a handful of open spots between now and spring 2017.”

With an eye towards the future, North River is aiming to add capacity that will eventually allow another 60 recreational boats and 20 commercial boats to be produced annually. Most boats are newly designed to meet current customer needs. Blocher explains, “We have several boats that are entirely new to North River, such as our Crew Transport boat and our Riverine shallow jet boat to name a couple.”

North River Boats only builds aluminum boats. Blocher spelled out that business strategy by saying, “We have very skilled personnel throughout our company with the majority of the production staff having over 10 years of experience. We believe in making the highest and best use of our limited capacity and building what we know best, which is aluminum boats. We have no intention of building other than aluminum boats.”

Beyond Our Shores

North River has also been exporting boats for several years. Aggressively concentrating on the Caribbean and Latin America markets, the firm typically ships three to five boats annually into this market. Blocher adds, “We recently completed three boats that went to Israel and are working on projects and quotes in many countries at this time.”

Closer to home, a relationship with Trinidad Pilots started through Almar Boats shortly after North River acquired Almar. The Pilots were looking for a more efficient and safer method of transporting their pilots. Their search took them to Almar Boats, and a factory visit was the first step in developing a long and mutually satisfying relationship.

Bridge Control Services Limited (BCSL) is based in Trinidad and Tobago and provides marine transport services to the Trinidad and Tobago Pilots’ Association and other companies in various sectors. A long-time North River customer, their fleet includes jet-propelled boats capable of speeds up to forty knots, all fully certified to effectively execute a wide array of services. Darren Josa, Director at BCSL, told Marine News in March, “We have 11 North River boats in our fleet, ranging in sizes from 38 feet up to 55 feet. The majority of BCSL’s fleet are pilot boats used for Launch Services and there is also one dedicated crew/ supply boat.”

Blocher told News in March, “I believe that we were one of the first companies to include roof top boarding for pilot transfers. By using roof top boarding, the pilot can enter/exit the vessel closer to the top of the ladder. The majority of incidents occur with the pilot falling from the ladder so by giving the pilot fewer rungs to climb we have improved safety for the transfer. This, combined with the speed of the vessels (approximately 40 knots), enables Trinidad Pilots to grow their business by opening up the vessels to various other uses as well as reducing the travel time to and from transfers.”

We asked Josa why BCSL had purchased so many North River Boats and he replied, “North River has continuously proven to be a reliable boat building supplier, who provides strong and unique vessel designs suitable to our company’s needs. We keep coming back because of their professionalism, competitive prices, excellent customer and after sales service, their dependability when it comes to meeting our time-frames for delivery and the quality and durability of the vessels. North River also offers a wide range of vessel designs.”

One of North River’s latest designs for BCSL is a crew transport vessel provides seating for 24 passengers and a maximum load of 3 tons of cargo. Service speed is very important to BCSL’s customers, so they require a service speed no less than 30 KT. The new boat will be fitted with triple Caterpillar C12 705hp marine diesel engines with ZF 360 transmissions and Hamilton HJ364 jets. Other features include an exceptional fendering system, and state-of-the-art navigational system.

Josa says that BCSL’s goal is to be the premier and most innovative maritime service provider in the region. “That being said, we always look for suppliers who can contribute to our overall goals,” he adds. And, while price is important to BCSL, Josa says it isn’t the only reason that they keep coming back, year after year. “The maintenance costs for the North River vessels are economical and parts for repairs are easily accessible,” he explains, adding quickly, “With regards to prices, North River’s prices are comparable with other competitors. However, what sets them apart from the competition is the customizability of their boats, the after sales service and the working relationship we have developed with their staff.”

Many Designs for Myriad Customers

According to Mike Blocher, a key aspect of North River’s success is the firm’s ability to custom design for a wide range of customers. With two in-house designers, North River will reach outside to get help when appropriate. Blocher explains, “We have a great design team and generally do the majority of design and calculations in-house. For the times that we do need to sub-contract a certified PE we use Boksa Marine Design in Florida. We also use a local PE in Seattle Washington for some of our US Coast Guard Sub Chapter T Passenger Inspected boats.”

The firm’s pilot boat designs are a perfect example of their design capabilities. “The twin diesel Hamilton Jet design is great for coming alongside ships at pilot transfer speeds. Traditional propeller designs can get ‘stuck’ to the side of the ship making it hard to pull away from the ship after the transfer is complete,” Blocher explains, adding, “With the twin diesel jets it is very simple. The ability to adjust the buckets during transfer not only helps keep the hull against the ship during the transfer but allows the operator to easily pull away when the transfer is complete. It is very important to work with Hamilton Jet on these pilot boats to get the cavitation ratio correct. Our background is with jet boats and we do an excellent job at making sure we pair the right hull with the right engine and jet combination.”

Out of those plans come many different types of vessels and the firm has delivered or is in the process of building a wide variety of hulls. The portfolio, in addition to its considerable recreational output, includes:

- 38’ Valor Fire Boat to North Kitsap Fire and Rescue in Washington State

- Two (2) Fire Boats for the U.S. Army

- 11 U.S. Navy Force Protection Large boats (fleet protection / law enforcement vessel)

- 33’ – 38’ Pilot Boat with twin or triple outboard propulsion and standard cabin configuration

- 40’ – 45’ Pilot Boat with standard cabin configuration (Choice of twin jet or twin propeller)

- 45’ – 57’ Pilot Boat with choice of standard or aft cabin (Choice of twin or triple jet or twin propeller)

Sectors, Service and Selection:

Thriving – and not just surviving – in boatbuilding today involves many things. For North River, it means delivering aluminum quality and variety to commercial, government, and recreational clients; domestic and foreign. CEO Brent Hutchings told Marine News, “Over the last three years, sales have tripled and we continue to see strong demand across the three primary market segments we serve: Recreational, commercial and government. We owe our success to our amazing employees who deliver the best quality and service available in the heavy-gauge aluminum market.”

At the same time, Hutchings also says that North River’s diversification strategy is deliberate, adding “Since boat building is an inherently cyclical business, North River has worked hard for many years to develop customers throughout the United States and the world. Our sales staff regularly exhibit at international trade shows to maintain our global focus. We also work to spread our exposure across industries and agencies within each geographic market.”

North River’s approach insulates the company against the economic cycle and is the foundation for its growth and success. The business model also enables knowledge transfer from one segment to the other. So far, it’s a winning formula, in good times and bad for the domestic boatbuilding markets. In any endeavor, being all things to all people is a difficult thing to do. North River Boats doesn’t claim to do that. Arguably, their business model is about as close as it gets.

(As published in the April 2016 edition of Marine News)

Read North River Boats Thrives in a Challenging Build Market in Pdf, Flash or Html5 edition of April 2016 Marine News

Other stories from April 2016 issue

Content

- Interview: Frank Foti - President & CEO, Vigor Industrial page: 12

- The Master’s Authority: a Vital SMS Caveat page: 18

- How Politics Impacts OPA 90 Responder Immunity page: 20

- Support for Uniform National Discharge Legislation Builds page: 22

- Manage and Mitigate Risk on the Water page: 26

- North River Boats Thrives in a Challenging Build Market page: 28

- AIS Regulations: New Responsibilities and Opportunities page: 40

- Workboat Comms: Controlling Connectivity Costs page: 44

- Pontoon Deck Preservation for Floating Dry Docks page: 48