Navigating the ABCs of SCR

By Joseph Keefe

On the way to Tier IV compliance, it turns out that experience counts.

In late February, the nation’s first Tier IV, Selective Catalytic Reduction (SCR) tugboat was christened. That’s probably not earthshaking news all by itself – after all, SCR isn’t all that new – but the event likely ushers in a new era of powerful domestic workboats that also come with a greener environmental footprint. How all of that comes together is a bigger story, and one which will play out again and again in the coming year or two. At the heart of it all is Crowley subsidiary Jensen Maritime Consultants, who today lead the design field with no less than seven Tier IV, SCR versions in development. Digging deeper, it isn’t hard to see why.

Below Deck, Behind the Scenes

The new Tier IV hull comes with a silver lining. With the larger size, customers can use it for multiple missions – something all operators are looking for in an increasingly competitive commercial environment. Jensen Vice President Johan Sperling explained the trend to Marine News in February, saying, “All these new vessels, they’re all multi-purpose tugs. For example, the 100’ foot design for Bay Delta has a half focs’le on it so that they can go out in rougher weather and do other things. That’s a key trend that we are seeing. And everything’s tighter – margins are tighter for everyone.”

It is here where Jensen excels, in part because of geography. “Operators have to figure out how to get maximum utilization out of their tugs and maybe for us, this is more intuitive, because we’re sitting right next to the harbor tug operators here at pier 17,” said Sperling, who adds, “So we hear their struggle every day, and they use these vessels for multiple purposes and one of the ways to do that is by making a multi-purpose tug. That comes with a back side because it costs more money to build it. And they have to determine how much more money they have to spend, and at what level of utilization for what compensation rate that they can get it back.”

The design challenges are many when it comes to building a new tug with Tier 4 and SCR. First and foremost, the increased physical footprint of the equipment comes into play. “Every tug, whether 90 or 100 feet LOA; are being maxed out. So whether you are adding tier four after treatment or something else, the engine rooms are just getting more and more packed. The second thing that has been a real challenge is that’s there is increased heat that both the engine manufacturers and the shipyards and everyone else didn’t take into account as much as they could have. We’ve had to increase flow of air into and out of the space,” he said. Sperling also reminds us, the technology is brand new. “We’ve seen it in cases where the solution didn’t lay out the way it was originally described. And then, you are redesigning on the fly and some of that is happening. But, arguably, that’s normal.”

Selective Catalytic Reduction

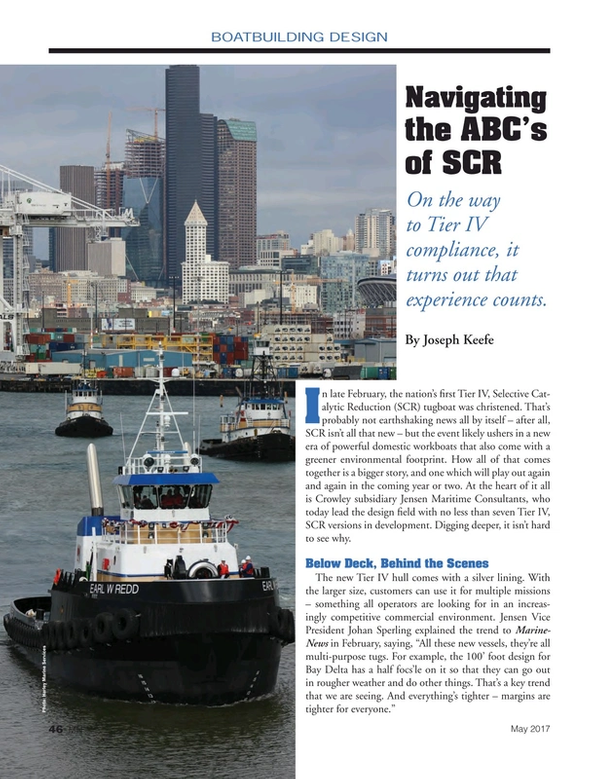

SCR systems scrub emissions by converting nitrogen oxide (NOx) into ammonia, which is then absorbed by ceramic bricks built into the engines. The technology significantly reduces the amount of NOx, particulate matter and hydrocarbons released into the environment, and makes the 120-foot vessel one of the cleanest-running tugboats in terms of marine emissions. In this case, the nation’s first Tier IV compliant tugboat employs a proprietary CAT SCR solution. Built at Diversified Marine’s shipyard in Portland, Oregon, Harley’s Earl W. Redd comes with Rolls-Royce US 255-P30-FP Z-drive propulsion and two Caterpillar 3516E diesel engines, for a rated 5,000 horsepower. Two, 125 kilowatt-hour (kW) John Deere generator sets provide the tug’s electrical power.

At the design phase, and later when the boat is in operation, SCR adds many obstacles to the end result. Operators want more horsepower, and the bollard pull race is anything but over. The Tier 4 requirement has just added another headache. But says Sperling, it’s nothing that’s not solvable. “It means more design, more engineering; it means warmer engine rooms and tighter spaces. In addition, the operators got to handle urea, which is a new thing. And, that’s another physical constraint – you have to put in the urea tank. It has to be completely freestanding tank, which, depending on the design, that’s not an easy thing to squeeze in. and, although it can be made smaller if you are going back to the same dock every day, the Harleys, the Bay Deltas and the Crowleys don’t always know they’ll be going back to the same dock every time.”

For customers that aren’t looking for pure assist and escort tugs – multi-missioned hulls – Jensen might design the urea tank bigger than 80 percent of their operational window. In the early days of SCR, flexibility in the design shop is everything. Sperling explains further, “Another client (Bay Delta) wanted a high horsepower tug and we let them know we’d need to make the tug bigger and they said, ‘as long as it meets my tonnage requirements, no problem.’ But, we can’t make the tug any bigger so if in future, the engine OEM needs more space, we may be in trouble from a tonnage regulation standpoint.” He also concedes, “It is not straightforward. But, I would say it is less of a headache for us than it is for the operator. There’s nobody in the world that has more experience with a tier 4 tug than Jensen.”

Decisions, Decisions

Today, Jensen is involved with at least five Tier IV compliant tugboats under construction, with options of up to eight. Clients include McAllister (2), Bay Delta (1), Harley (1) and one more [undisclosed] client. The McAllister tugs will be their first to utilize high-efficiency catalytic after-treatment technology to reduce emissions and will have an approximate bollard pull of 90 short tons. On the other hand, says Johan Sperling, workboat operators have other options – but these come with caveats.

“It’s all regulatory at this point. I think the early adapters, there may have been a few who wanted to be green, but today, you have no choice. It’s too late now to plan a project and not be Tier 4 unless you go with diesel electric or a hybrid system. Above 804 HP, you must go Tier IV.”

A so-called “tier beater” arrangement – two or three smaller engines in tandem is feasible, but regardless of what an operator decides, the cost will increase. Those alternatives are there, but are more prevalent with lower horsepower assist tugs. There’s always a trade off – a series of smaller, ‘tier beater’ engines might require a large engine room, a wider boat and compromises somewhere else on the boat.

There is, says Sperling, a significant uptick in information being shared about diesel electric and/or hybrid arrangements and/or technology. “A lot of people don’t like urea – I don’t blame them. The after treatment system can be large, it is warm; it has all kinds of things that we’re not used to. So, people are looking at these other opportunities, but we just haven’t seen as much of it – yet. If you look internationally, it is being deployed.”

Today, the alternative technology is there, but the economics are not panning out. And here, unlike in Europe, there’s no advantage to being a little bit greener. For those operators choosing to go LNG, you might have a Chief engineer who has been running diesels for 25 years. Now, they need to learn new technology. That costs money. Projecting ahead just a bit, Sperling opines, “We’re in this weird space where people haven’t decided exactly what to do with the Tier 4 challenge. I happen to think that a lot of it is driven by oil prices and if we see prices go in a favorable direction for LNG, you might see LNG tugs in the harbor.”

Unfortunately, the price differential between an SCR engineered Tier 4 solution, hybrid, and/or LNG or dual fuel systems aren’t necessarily a straightforward calculation. But, says Sperling, Jensen is ahead of that curve as well. “There’s fuel consumption, there’s maintenance to think about; it is a huge amount of work – and we’ve done a ton of that for Crowley. We keep that in house. But, the capital costs between the other options and SCR is getting closer.” Bottom line? Sperling says that some customers feel that the SCR version is closer to what they’re used to for the mission(s) of their fleet. That said, “SCR – it is cheaper today – but if you plot those two lines, they are getting closer and closer. At some point probably, capital costs are the same – it’s a matter with what they are comfortable with,” he adds.

Following its christening, the Earl W. Redd joined Harley’s Olympic tug-and-barge operations along the U.S. West Coast, including in Alaska, the Puget Sound and on the Columbia River. Eventually, at least six and possibly seven more SCR enhanced, Tier IV compliant tugs will join the collective U.S.-flag workboat, from sea to shining sea. They’ll be built in different yards and be operated by different firms in different places with differing missions, but in the end, they’ll all have one thing in common: a clean, regulatory compliant SCR emissions solution that’s been skillfully designed by Jensen to maximize performance while giving up as little as possible in operational capabilities.

(As published in the May 2017 edition of Marine News)

Read Navigating the ABCs of SCR in Pdf, Flash or Html5 edition of May 2017 Marine News

Other stories from May 2017 issue

Content

- Op/Ed: USCG Forges the Future of Navigation page: 18

- Subchapter M Survey Reports page: 20

- OP/Ed: CVIDA Good for Environment & Economy page: 24

- Rolling on the River with CORBA page: 30

- Gulf of Mexico is Ground Zero for the Jones Act page: 36

- Rapp Marine Deck Equipment Rounds out New Harley Barges page: 40

- New Approaches to Inland Infrastructure Renewal page: 42

- Navigating the ABCs of SCR page: 46

- Tech File: HydroComp NavCad for Optimized Design page: 50