Page 27: of Marine Technology Magazine (May 2008)

Undersea Defense Edition

Read this page in Pdf, Flash or Html5 edition of May 2008 Marine Technology Magazine

www.seadiscovery.com Marine Technology Reporter 27 towards rehabilitation. The main rehabilitation plan was to bring in two land-based drill rigs which were to drill down to the site of the rockfall area, pump grout to form a large plug in the fall. Once set in place and proved to be sealing, the mine could be dewatered on the downstream side so that rehabilitation could proceed. The second approach involved Cameco contracting Nuytco Research, in Vancouver, BC, to provide a robotic option to perform a condition assessment of the mine in the region of the open bulkhead door and of the door itself. To support them in this undertaking, Nuytco contracted SeaView

Systems to provide their SeaEye Falcon DR remotely- operated vehicle (ROV). Together the two companies took a 'white paper" development approach with the only restriction to the problem being the state-of-the-art of applicable underwater technology. As visibility was expect- ed to be near zero, the need for the best available real-time remote imaging equipment and accurate navigation was identified as being a critical requirement for the successful completion of the project.

To address the issue of real-time imaging equipment in poor visibility situations, Nuytco and SeaView identified: (1) A SoundMetrics DIDSON imaging multibeam sonar, mounted to on a tilt platform to track the pri- mary Falcon camera (2) A CDL MiniPulse profiling sonar (3) An Imagenex 881a imaging sonar (4) Two Outland Technology Pan & Tilt cameras (5) Two 150W DeepSea Power and Light halogen lamps to be deployed in addition to the standard low light

SeaEye Camera.

To address the issue of real-time navigation, an inertial navigation system was necessary. Having had earlier expe- rience with deploying a Doppler-velocity log-aided

Inertial Navigation System (INS) on the ROV, Mr.

Matthew Cook at SeaView Systems recommended that the ROV be positioned using a CDL Minipos INS system and that Nuytco contract SeaView's historical partner in

INS operations, SeaVision Marine Services LLC in

Connecticut.

Aided Inertial Navigation

The CDL MiniPos is an INS that is built around a

Kearfott T16 Ring Laser Gyroscope (RLG). A monolithic

RLG provides highly accurate heading, pitch, and roll information in real time at a rate of nearly 20 Hz. This information, when paired with the data from linear accelerometers in three dimensions (x, y, and z) can pro- duce an accurate dead-reckoning position for the INS in

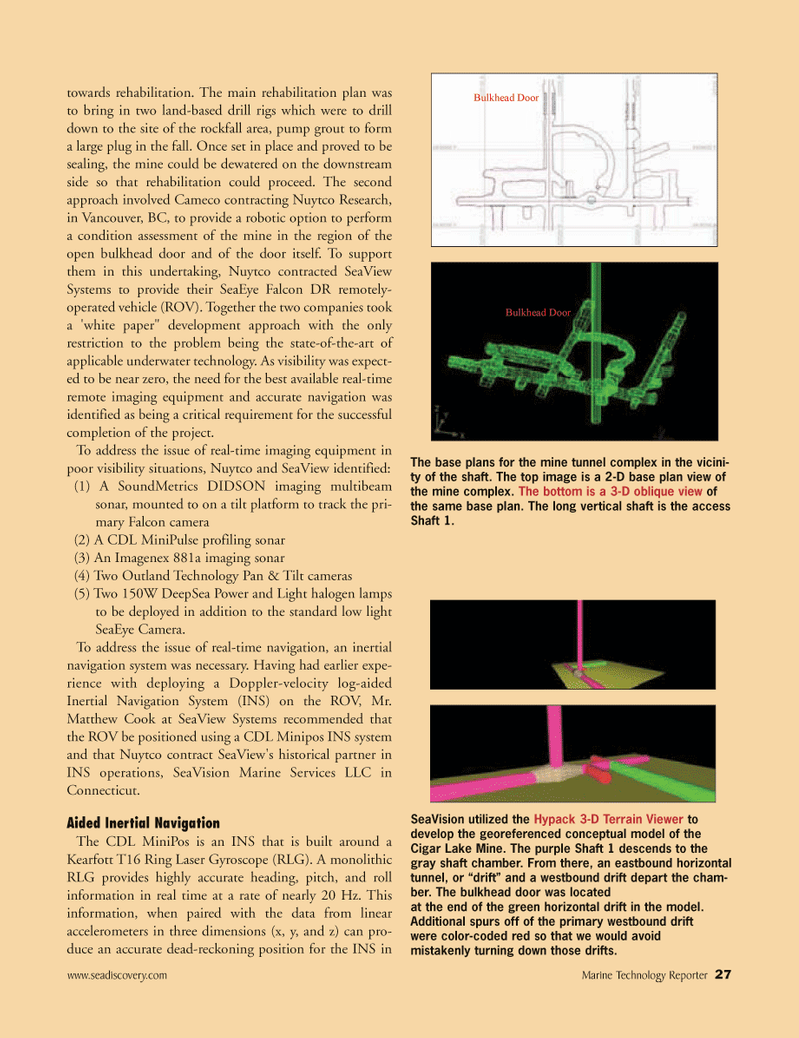

Bulkhead Door

Bulkhead Door

The base plans for the mine tunnel complex in the vicini- ty of the shaft. The top image is a 2-D base plan view of the mine complex. The bottom is a 3-D oblique view of the same base plan. The long vertical shaft is the access

Shaft 1.

SeaVision utilized the Hypack 3-D Terrain Viewer to develop the georeferenced conceptual model of the

Cigar Lake Mine. The purple Shaft 1 descends to the gray shaft chamber. From there, an eastbound horizontal tunnel, or “drift” and a westbound drift depart the cham- ber. The bulkhead door was located at the end of the green horizontal drift in the model.

Additional spurs off of the primary westbound drift were color-coded red so that we would avoid mistakenly turning down those drifts.

MTR#4 (17-32).qxd 5/13/2008 9:59 AM Page 27

26

26

28

28