Page 26: of Marine Technology Magazine (May 2008)

Undersea Defense Edition

Read this page in Pdf, Flash or Html5 edition of May 2008 Marine Technology Magazine

accurate structural layout information available, it is possible \ to develop useful three-dimensional concept models that can be managed, in real time, in order to provide a general understanding of the location and orientation of an ROV.

These models can vary in complexity, from the custom full-physics training models that are becoming more pop- ular in the ROV industry, to much more simple on-the- fly models that can be developed using off-the-shelf soft- ware. The technology exists, in the form of Doppler

Velocity Log-aided inertial navigation systems, to provide adequate positioning and orientation information for the

ROV that can be fed into the models; these models can then be utilized to supplement real-time inputs from video and sonar sensors to enhance overall situational awareness.

Flooded Mine: A Challenging Environ

For the purposes of this article, we shall focus on a con- fined access environment with poor visibility where water depths and access required remoteinvestigation: specifical- ly, a flooded mine with water depths approaching 1500 feet. The Cameco Corporation is a large producer of ura- nium based in Canada. In October 2006, the main mine at their developmental Cigar Lake facility in northern

Saskatchewan suffered a roof cave-in resulting in the mine flooding at a rate of approximately 15,000 to 20,000 gal- lons per minute.

The mine had been designed to contain such an event with the installation of two 12-foot diameter highpressure bulkhead doors located within the mine so that, when closed, the doors would isolate the ore body floors (in development) from the mill/production facility area (near completion), allowing the mine to flood, but to protect the mill/production assets. During evacuation, one door was closed successfully but the other failed to seal despite heroic efforts on the part of the miners. After several attempts, and with frigid water flooding through the door and increasing in volume at an alarming rate, it became apparent that the door was not going to able to be closed.

Reluctantly, the miners evacuated the mine.

The failed bulkhead door was located approximately 1500 feet below ground surface. By the time flooding had stabilized, water had completely flooded the mine and risen within the single vertical access shaft to within 55- feet below ground surface.

Given the estimated $19 billion value of the mine, no time was spared by Cameco in starting on a recovery pro- gram. They decided upon a two pronged approach 26 MTR May 2008

A view down Cigar Lake Mine Shaft 1. The actual floor to be investigated was 1500 feet below the ground surface; water had flooded to within 60-feet of the ground surface.

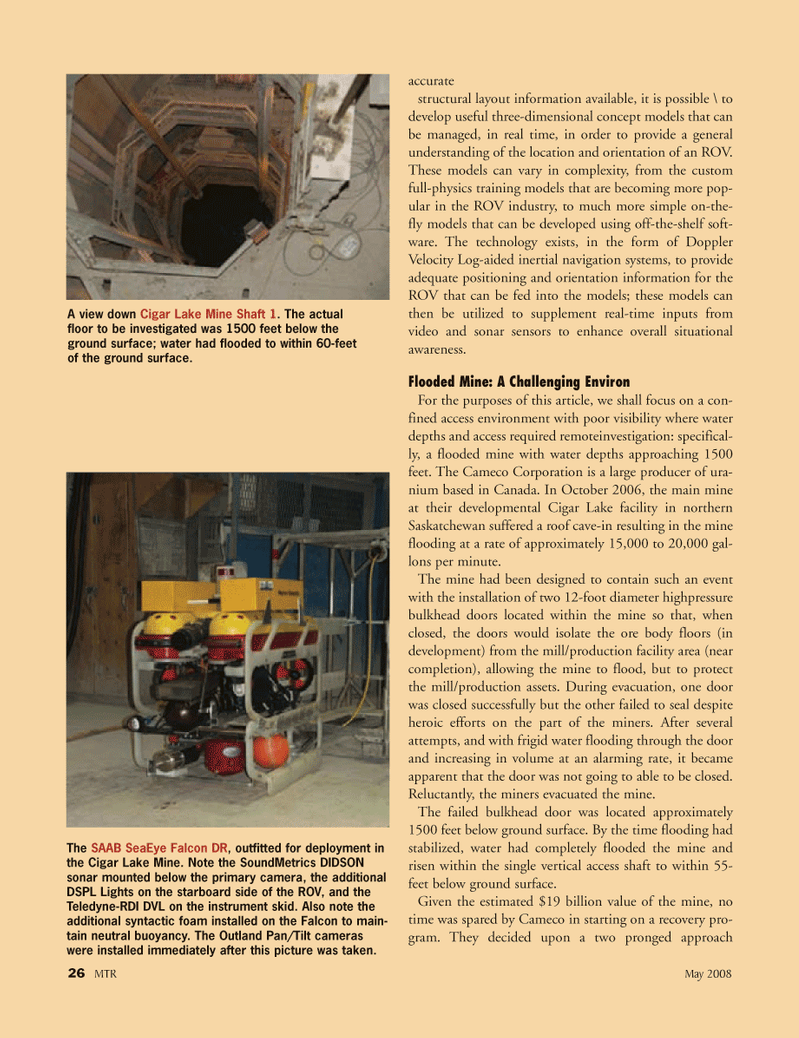

The SAAB SeaEye Falcon DR, outfitted for deployment in the Cigar Lake Mine. Note the SoundMetrics DIDSON sonar mounted below the primary camera, the additional

DSPL Lights on the starboard side of the ROV, and the

Teledyne-RDI DVL on the instrument skid. Also note the additional syntactic foam installed on the Falcon to main- tain neutral buoyancy. The Outland Pan/Tilt cameras were installed immediately after this picture was taken.

MTR#4 (17-32).qxd 5/13/2008 9:59 AM Page 26

25

25

27

27