Page 42: of Marine Technology Magazine (May 2014)

AUV Operations

Read this page in Pdf, Flash or Html5 edition of May 2014 Marine Technology Magazine

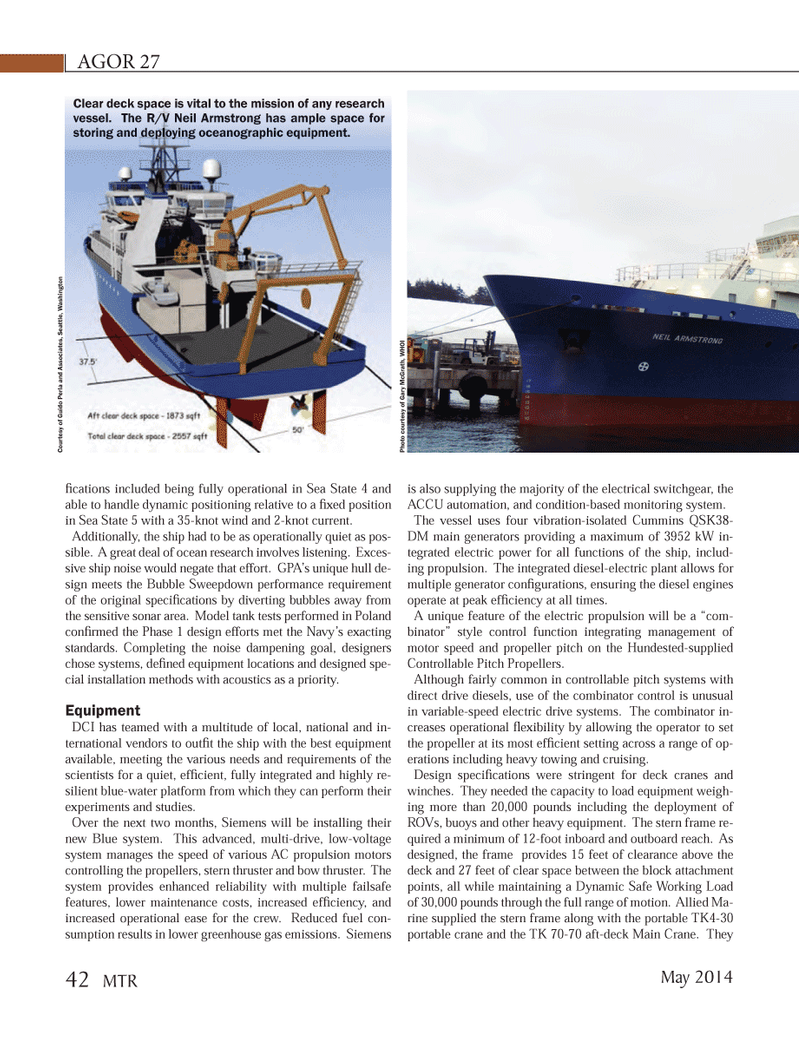

AGOR 27 Þ cations included being fully operational in Sea State 4 and able to handle dynamic positioning relative to a Þ xed position in Sea State 5 with a 35-knot wind and 2-knot current. Additionally, the ship had to be as operationally quiet as pos- sible. A great deal of ocean research involves listening. Exces- sive ship noise would negate that effort. GPAÕs unique hull de- sign meets the Bubble Sweepdown performance requirement of the original speciÞ cations by diverting bubbles away from the sensitive sonar area. Model tank tests performed in Poland conÞ rmed the Phase 1 design efforts met the NavyÕs exacting standards. Completing the noise dampening goal, designers chose systems, deÞ ned equipment locations and designed spe- cial installation methods with acoustics as a priority. EquipmentDCI has teamed with a multitude of local, national and in-ternational vendors to outÞ t the ship with the best equipment available, meeting the various needs and requirements of the scientists for a quiet, efÞ cient, fully integrated and highly re- silient blue-water platform from which they can perform their experiments and studies. Over the next two months, Siemens will be installing their new Blue system. This advanced, multi-drive, low-voltage system manages the speed of various AC propulsion motors controlling the propellers, stern thruster and bow thruster. The system provides enhanced reliability with multiple failsafe features, lower maintenance costs, increased efÞ ciency, and increased operational ease for the crew. Reduced fuel con- sumption results in lower greenhouse gas emissions. Siemens is also supplying the majority of the electrical switchgear, the ACCU automation, and condition-based monitoring system. The vessel uses four vibration-isolated Cummins QSK38- DM main generators providing a maximum of 3952 kW in- tegrated electric power for all functions of the ship, includ- ing propulsion. The integrated diesel-electric plant allows for multiple generator conÞ gurations, ensuring the diesel engines operate at peak efÞ ciency at all times. A unique feature of the electric propulsion will be a Òcom-binatorÓ style control function integrating management of motor speed and propeller pitch on the Hundested-supplied Controllable Pitch Propellers. Although fairly common in controllable pitch systems with direct drive diesels, use of the combinator control is unusual in variable-speed electric drive systems. The combinator in- creases operational ß exibility by allowing the operator to set the propeller at its most efÞ cient setting across a range of op- erations including heavy towing and cruising. Design speciÞ cations were stringent for deck cranes and winches. They needed the capacity to load equipment weigh- ing more than 20,000 pounds including the deployment of ROVs, buoys and other heavy equipment. The stern frame re- quired a minimum of 12-foot inboard and outboard reach. As designed, the frame provides 15 feet of clearance above the deck and 27 feet of clear space between the block attachment points, all while maintaining a Dynamic Safe Working Load of 30,000 pounds through the full range of motion. Allied Ma- rine supplied the stern frame along with the portable TK4-30 portable crane and the TK 70-70 aft-deck Main Crane. They Courtesy of Guido Perla and Associates, Seattle, Washington Photo courtesy of Gary McGrath, WHOI Clear deck space is vital to the mission of any research vessel. The R/V Neil Armstrong has ample space for storing and deploying oceanographic equipment. May 201442 MTRMTR #4 (34-49).indd 42MTR #4 (34-49).indd 425/12/2014 4:19:12 PM5/12/2014 4:19:12 PM

41

41

43

43