Page 58: of Marine Technology Magazine (June 2014)

Hydrographic Survey

Read this page in Pdf, Flash or Html5 edition of June 2014 Marine Technology Magazine

Products

Axis: New Security Cameras

The AXIS Q60-S PTZ Dome Network Cameras in nitrogen-pressurized stainless steel casings can resist the corrosive effect of sea water and cleaning chemicals, and withstand high-pressure steam cleaning. Pressurized nitrogen prevents inter- nal condensation. Axis Communications launched three outdoor-ready, marine- grade stainless steel cameras that enable 360° coverage of wide areas in resolu- tions up to HDTV 1080p and great zoomed-in detail with up to 36x optical zoom.

AXIS Q60-S cameras, with SAE 316L stainless steel and a nylon clear dome cover, can operate in -30°C to 50°C (-22°F to 122°F). They have IP66, IP6K9K,

NEMA 4X and MIL-STD-810G 509.5 approvals, ensuring protection against dust, rain, high pressure/steam jet cleaning, snow, ice and salt fog. www.axis.com

Hardide Coatings

Hardide Coatings completed its fi rst application for a remotely operated vehicle (ROV) for Seatronics with exceptional test results, the company claims, resulting in improved performance. Since using the coating on a critical part of the thruster system, the Predator ROV manufactured by Seatronics reportedly has increased in performance and power, with critical wear issues also improved. David Currie, Managing Director at Seat- ronics, said: “The Observation-class ROV sector is a growing market for us and we want to make the Preda- tor as maintenance-free as possible. The Hardide coat- ing solved the wear issues we were facing and increased the performance of the ROV. Using the Hardide coating on the Predator was like tuning a car to get more miles per gallon and getting F1 performance.” Seatronics manufactures the Predator ROV mainly for the oil and gas market to support operations using a diver or larger

ROV to provide backup and support. www.hardide.com

Free Annual Calibration

Tritex NDT Ltd. is offering free annual calibration for the life of its range of products, including the Multi- gauge 3000 Underwater Metal Thickness Gauge. The gauge is used to measure metal thickness to determine levels of corrosion, without having to fi rst remove coat- ings. Only the metal substrate is measured due to the

Multiple Echo technology used. The Multigauge 3000 is a simple, robust underwater thickness gauge designed to survive harsh conditions that exist in the offshore and underwater environment. The bright red 10mm LED display ensures the measurements can be seen by the diver, even in poor visibility. The gauge is hand held and only one probe type is required. www.tridexndt.com ... Worth 1000 Words ...

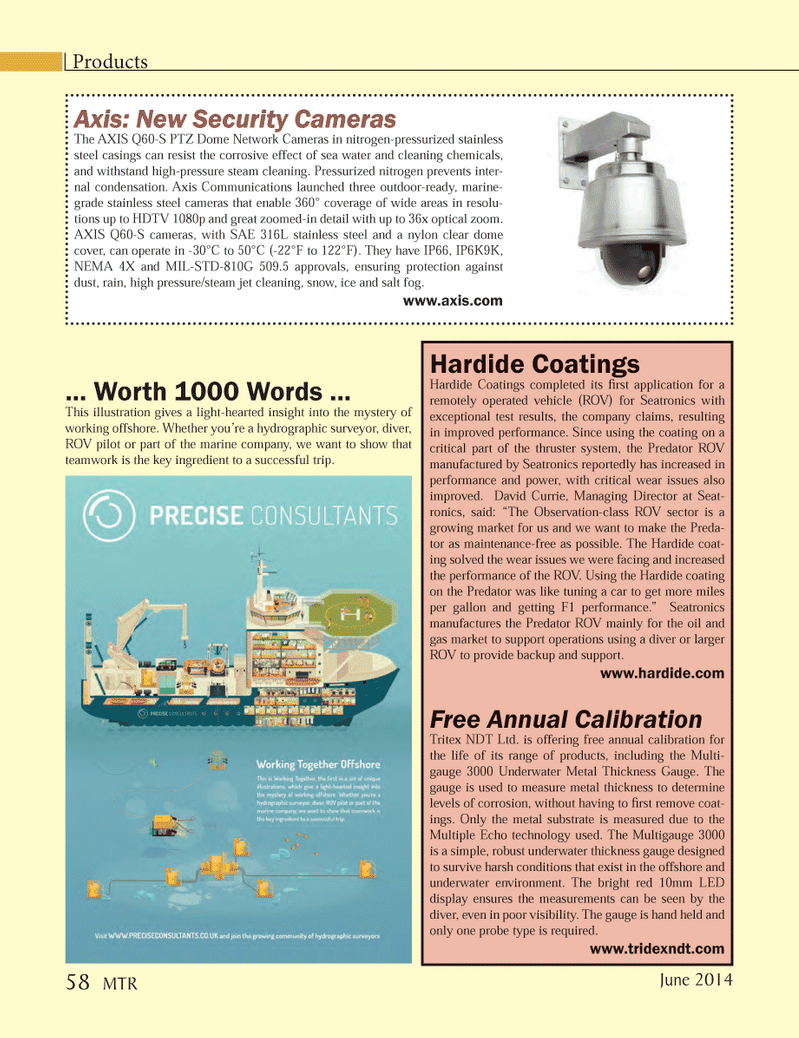

This illustration gives a light-hearted insight into the mystery of working offshore. Whether you’re a hydrographic surveyor, diver,

ROV pilot or part of the marine company, we want to show that teamwork is the key ingredient to a successful trip.

June 2014 58 MTR

MTR #5 (50-64).indd 58 6/9/2014 11:03:19 AM

57

57

59

59