Page 59: of Marine Technology Magazine (June 2014)

Hydrographic Survey

Read this page in Pdf, Flash or Html5 edition of June 2014 Marine Technology Magazine

Sonardyne System to

Monitor North Sea

CO2 Leaks

Sonardyne International is taking part in a new Energy Tech- nologies Institute (ETI) project within the Carbon Capture

Storage (CCS) program to develop a Carbon Dioxide (CO2) marine and shallow subsurface monitoring system for under- ground CCS sites in the North Sea. The system will monitor for any CO2 leakage from saline aquifers and offshore stor- age sites such as oil and gas fi elds, both active and depleted.

The development of a U.K.-based North Sea CCS industry is an important element in the government’s initiative to sig- nifi cantly cut greenhouse gas emissions by 2050, mitigat- ing against high future energy costs and for developing high value, low carbon industries. Other members of the Con- sortium are lead participant Fugro GEOS Ltd., the National

Environment Research Council (NERC – as represented by the National Oceanography Centre and British Geological

Society), Plymouth Marine Laboratory and the University of Southampton.

Using technologies already proven in the offshore and oceanographic industries, combined with new remote sens- ing technology, the consortium will develop an integrated leak detection system that is capable of both wide area cov- erage by AUVs/ASVs (Autonomous Underwater Vehicles/

Autonomous Surface vehicles) and continuous automated monitoring of high risk areas. For these sites, the use of

Sonardyne’s Automatic Leak Detection Sonar (ALDS) has been proposed. ALDS is both an active and passive sonar capable of monitoring more than one billion cubic feet of water for the smallest of leaks. The system is fully auto- mated, offering reliable detection, rapid notifi cation and lo- calization of leaks. It provides continuous 360° coverage, detecting leaks after only tens of seconds.

As the data is gathered from both ALDS, the AUVs/ASVs and other monitoring technologies, it will be relayed to shore using a combination of wireless acoustic and satel- lite communications and existing reservoir infrastructure acting as surface-to-shore relay stations. Sonardyne’s Au- tonomous Monitoring Transponders (AMTs) will form the core power, data logging and communications backbone for this data sensing and relay. AMT’s autonomously acquire acoustic ranges and sensor data is then time-stamped and logged internally for recovery via the integrated high-speed acoustic telemetry modem. This autonomy allows measure- ments to be made over long periods of time and a wide range of sensors for the detection of CO2 can be interfaced and integrated, providing an ultra-low power platform for up to fi ve years unattended deployment. www.sonardyne.com

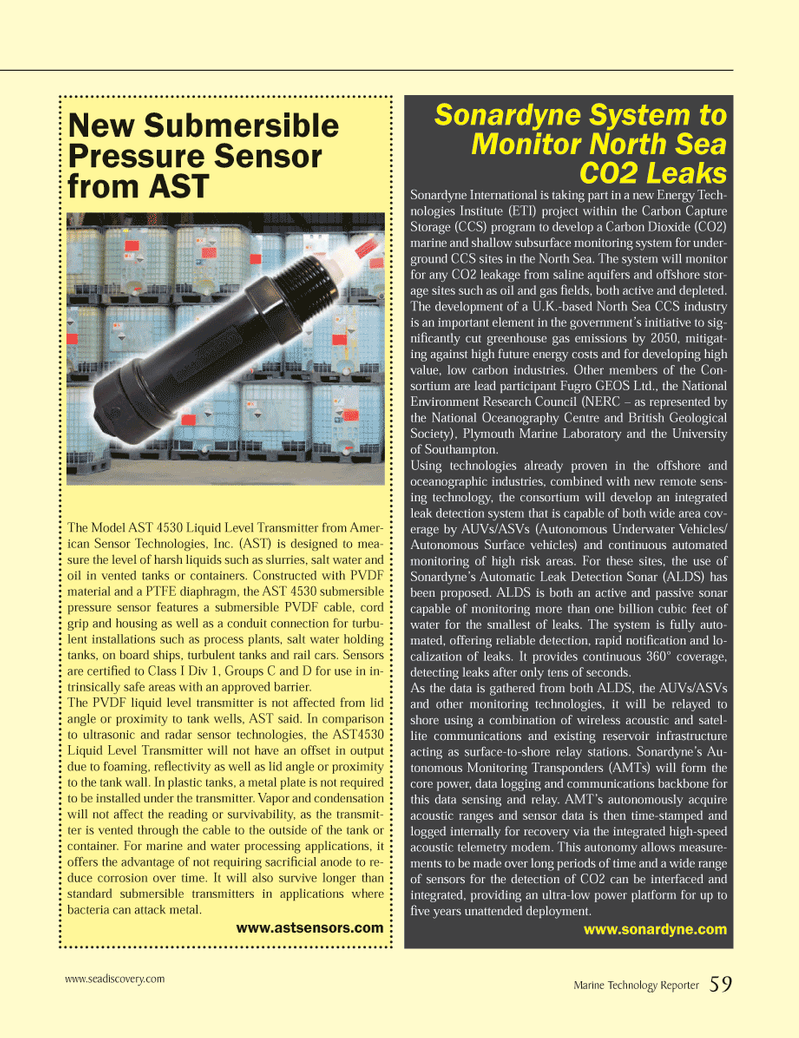

New Submersible

Pressure Sensor from AST

The Model AST 4530 Liquid Level Transmitter from Amer- ican Sensor Technologies, Inc. (AST) is designed to mea- sure the level of harsh liquids such as slurries, salt water and oil in vented tanks or containers. Constructed with PVDF material and a PTFE diaphragm, the AST 4530 submersible pressure sensor features a submersible PVDF cable, cord grip and housing as well as a conduit connection for turbu- lent installations such as process plants, salt water holding tanks, on board ships, turbulent tanks and rail cars. Sensors are certifi ed to Class I Div 1, Groups C and D for use in in- trinsically safe areas with an approved barrier.

The PVDF liquid level transmitter is not affected from lid angle or proximity to tank wells, AST said. In comparison to ultrasonic and radar sensor technologies, the AST4530

Liquid Level Transmitter will not have an offset in output due to foaming, refl ectivity as well as lid angle or proximity to the tank wall. In plastic tanks, a metal plate is not required to be installed under the transmitter. Vapor and condensation will not affect the reading or survivability, as the transmit- ter is vented through the cable to the outside of the tank or container. For marine and water processing applications, it offers the advantage of not requiring sacrifi cial anode to re- duce corrosion over time. It will also survive longer than standard submersible transmitters in applications where bacteria can attack metal. www.astsensors.com www.seadiscovery.com

Marine Technology Reporter 59

MTR #5 (50-64).indd 59 6/9/2014 11:03:53 AM

58

58

60

60